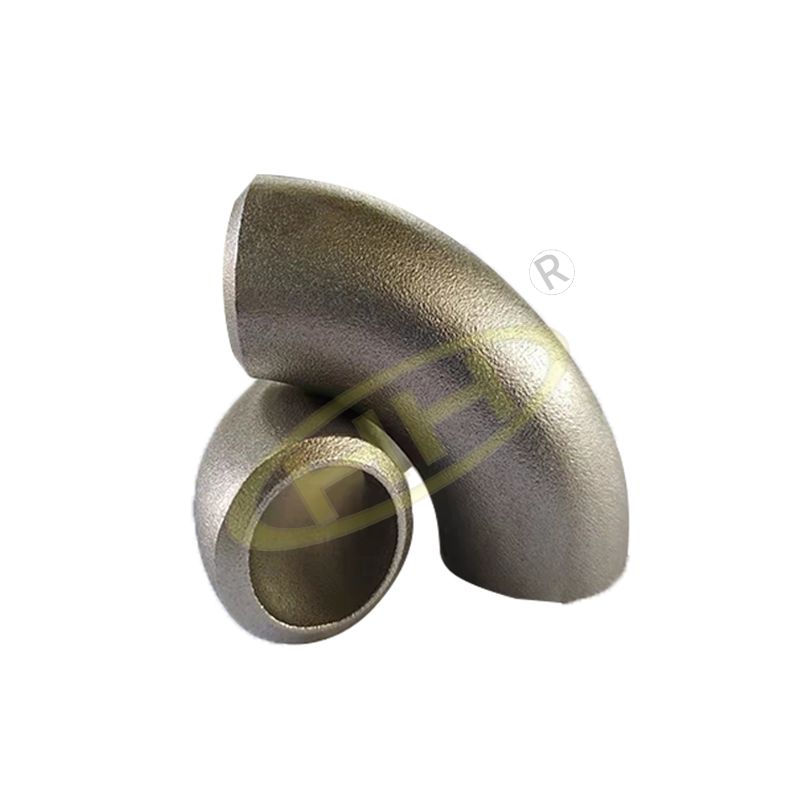

Casting Powder

During continuous casting process, in order to compensate heat to the crystallizer, make the liquid surface inside crystallizer form into slag quickly, and facilitate smooth and continuous casting, our company has developed new casting powder. G-High casting power can reduce the probability of defective billets. Customers can choose suitable casting power according to different steel grade, casting format and casting speed. According to the content of carbon, we can produce casting powder especially for high carbon steel, medium carbon steel, mild steel and stainless steel. We can produce casting powder according to customers’ requirement. Besides casting power for crystallizer, we also produce die casting powder, which is widely used in casting & foundry industry, and it can remarkably improve the billet yield.

Other supplier products

|

|

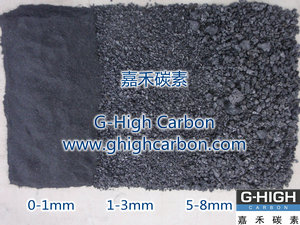

Low Nitrogen Calcined Petroleum Coke |

By strictly practicing YB/T 192-2001, G-High Carbon develops many kinds of carbon-additives according to customers’ requirements, which conta... |

|

|

Graphite Petroleum Coke |

G-High Graphite Petroleum Coke is widely used as carburant in the steel-making industry and precision casting industry, reduction pregnant agent in... |

|

|

Low Nitrogen Carbon Additive |

By strictly practicing YB/T 192-2001, G-High Carbon develops many kinds of carbon-additives according to customers’ requirements, which conta... |

|

|

Low Nitrogen Recarburizer |

By strictly practicing YB/T 192-2001, G-High Carbon develops many kinds of carbon-additives according to customers’ requirements, which conta... |

|

|

Fluorite |

Fluorite belongs to mineral products and its main ingredient is calcium fluoride, which takes up 40-90%. Fluorite with 75% min calcium fluoride can... |

All supplier products

Same products