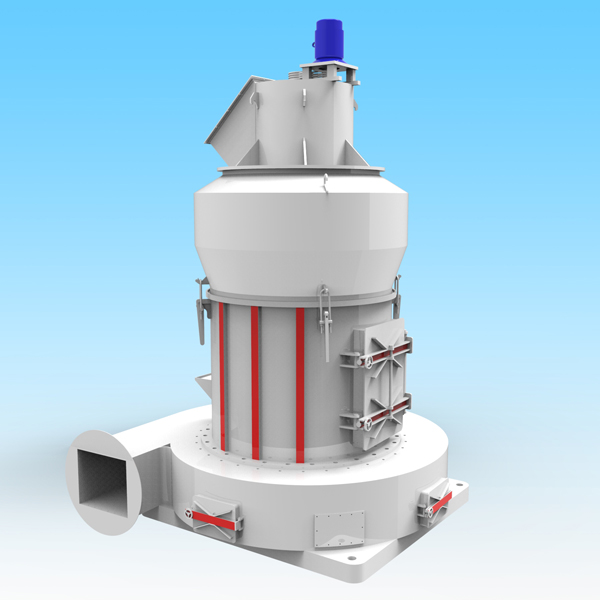

GK1720A Pendulum Grinding Mill

GK1720A Grinding Mill is designed by our technicians based on GK1720 mill.This is a large type mill with optimized design.

Technical & Structural Benefits of GK1720A Pendulum Grinding Mill:

Optimized shock-absorption design for the main unit, reduce vibration when the mill running.

Optimized design for the main unit structure, improve overall strength and rigidity.

The innovative design of the "maintenance-free device" for grinding roller assembly, Refill grease every 30 days.

Optimize inside design of the main unit, keep the roller and grinding ring abutting contact during running, improve grinding efficiency and operational reliability, and reduce the high failure rate of vertical pendulum grinding mill.

Equipped with water cooling structure for reducer of the main unit. Reducer adopts German technology.

Automatic control for air blower valve, reduce operating labor intensity。

Integral installation of air blower; water cooling system ensures running efficiency.

Running more smoothly, High capacity, low noise, energy saving.

Intelligent control. The one button start and stop system and fault alarm system reduce operating personnel.

|

Model |

Max Feeding Size |

Product Fineness (mash) |

Capacity |

Gross Weight |

Total Installed Power |

|

GK2500 |

≤35mm |

80-325mesh |

kg/h |

66t |

625kw |

|

GK2150 |

≤35mm |

80-325mesh |

kg/h |

64t |

548kw |

|

GK1720A |

≤35mm |

80-325mesh |

6000-25000kg/h |

49t |

|

|

GK1620A |

≤30mm |

80-325mesh |

3000-18000kg/h |

||

|

GK1500 |

≤20mm |

80-325mesh |

2500-16000kg/h |

31t |

242kw |

|

5R4128 |

≤20mm |

80-325mesh |

2000-14000kg/h |

220kw |

|

|

5R4125 |

≤20mm |

80-325mesh |

2000-14000kg/h |

202kw |

|

|

GK1280 |

≤20mm |

80-325mesh |

1500-10000kg/h |

19t |

|

|

4R3220 |

≤20mm |

80-325mesh |

1000-7000kg/h |

Preparation before operation of GK1720A Pendulum Grinding Mill:

Check that the supply voltage meets corresponding requirements. Don't start the machine when the voltage is lower than 360 v. Check the electric circuit in the light of drawing.

Check all joint bolts for tightness, especially the bolts in host chamber.

Check drive belt for looseness and tightness. The mainframe can rotate freely by moving it with hands. Check grinding rollers for flexible movement. The buffer spring above the roller assembly in the main unit should be screwed up to 185mm(see drawing 2); the length of four spring should be kept on the same size.

See that governor valve of inlet pipe air blower is in "off" position(it is automatically controlled by the pneumatic valve. Before start the blower, power on it to test it first. Normally the positioning pin is fixed to the positioning hole. After electromagnetic switch valve is energized, under the effect of air pressure, the cylinder activities section stretches out and drive the connecting rod, then the valve plate is open. When it is powered off, the valve is closed.)( see drawing 4)

Check the chain of the elevator for looseness and tightness.

Lubricate all parts according to the lubrication table. Lubricants are filled before use.The grease is clean. Check all the joints for oil leakage.

Regulate the discharge opening of jaw crusher in line with the nature of materials. The particle size is less than 35 mm.

Check motors for rotating direction.

Check pulse dust collector:

Start induced draft fan. Check shell and discharge valve for air leakage.

Keep the pressure of air compressor piping system on 0.5-0.7 MPa. Check

We provide roller ball mill,contact us now.

Send product request

Other supplier products

| Pendulum Grinding MillPendulum Grinding Mill | Pendulum Grinding Mill Pendulum mill is also called as suspension roller or Raymond mill. It is a "ring and roller" powder-making mill equipment, w... | |

| Pendulum Grinding Mill | Pendulum millis also called as suspension roller or Raymond mill. It is a "ring and roller" powder-making mill equipment, which is combined with ai... | |

| Raymond Mill | As national powder R&D center, GUIKUANG has made much efforts and contributions for the development of powder industry more than 40 years. Raym... | |

| Vertical Grinding Mills | vertical milling machines GKLM series vertical grinding mill is one advanced powder making mill through our engineer research and experience a... | |

| Ball Mill | The Handling Materials and Main Types of Ball Mill: Ball mill is a key equipment for grinding materials, widely used in powder-making production li... |

Same products

| Metal Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Metal Insulated Composite Panel Systems The system is composed of fire-resistant composite metal... | |

| AluzincMg-Al-Zn Alloy Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | AluzincMg-Al-Zn Alloy Composite Panel Systems Introducing magnesium aluminum zinc composite pane... | |

| Aluminium Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Aluminium Insulated Composite Panel Systems This system features composite panels manufactured i... | |

| 3D Aluminium Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | 3D Aluminium Composite Panel Systems The 3D Aluminium Composite Panelutilizes aluminum alloy she... | |

| Calcium Silicate Board Integrated Exterior Wall Insulation | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Calcium Silicate Board Integrated Exterior Wall Insulation and Decoration Panel Leboomoffers hig... |