Sheet Metal Bending

Sheet metal bending is a process in which a metal sheet is passed through a pressure device and a special mold to transform a flat sheet into a three-dimensional process called bending.

Due to the different materials, thicknesses, lengths, and widths of the plates and the different shapes and angles to be formed, there are bending machines with different tonnage and size pressure equipment, with upper and lower molds of different heights, shapes and V sizes. Special molds with special shapes, such as u bend sheet metal and z bending sheet metal. As one of the most professional sheet metal bending manufacturers, we have the AIGENI Bending Machine and HRIGEI Bending Machine. Bending is a cold working process. Under the pressure of the upper or lower die of the bending machine, the metal sheet is first elastically deformed and then enters plastic deformation. At the beginning of plastic custom sheet metal bending, the sheet is free to bend. The mold or the lower mold presses the sheet material, and the inner surface of the sheet and the lower mold V-groove gradually closes, and the radius of curvature and the bending arm are gradually reduced, and the pressing is continued until the stroke ends, so that the upper and lower molds and the sheet metal are three. The point is close to full contact, and a V-bend is completed at this time, which is commonly known as a bend. Our tolerances are less than 5.0 for sheets of ±0.1 and 5.0 or more for ±0.3.

We are professional sheet metal bending companyand we provide the sheet metal bending services.

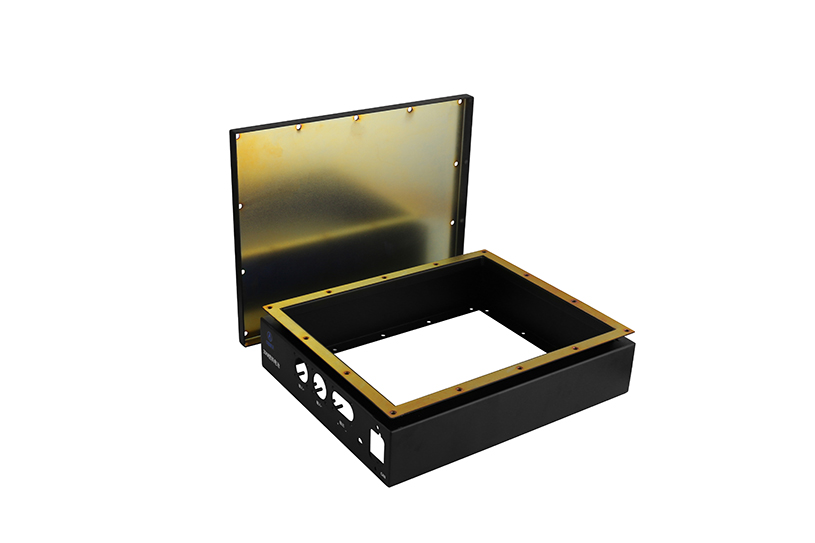

Computer enclosure

OEM Laser Cutting custom computer case sheet metal part,computer enclosure Computer host shell, computer chassis, accessories, cabinets, various of electronic sheet metal bending parts.

Material: Aluminum 5052, Carbon steel, Stainless steel, etc

surface treatments Finish: black anodize, Plating, Painting, Powder coating and deburred.

Process: bending (total process: blanking - flat grinding - bending - pressure riveting - welding - surface treatment)

Expansion: Usually, the chassis or the electric cabinet are made of cold-rolled steel sheets of 6 mm or less, or galvanized sheets and electrolytic plates, because it is convenient and the cost is not high.

If it is made of aluminum plate, it is recommended to buy the model 5052 aluminum plate, because this aluminum plate has better tensile resistance and can be bent. High food-grade is required.

Stainless steel 304.316.430, anti-oxidation, easy to form, high hardness.

Electronic power box

Material: secc、spcc、sgcc

Surface treatments finish: Powder coating and deburred.

Process: sheet metal forming bending

Tolerance: +/-0.1mm

Sheet Metal Bending Materials

Materials of sheet metal bending parts include SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel

Sheet Metal Bending Custom Solutions

Sending the drawing or your demand to us. Let us know your products’ details and we could offer the sample for you.

Send product request

Other supplier products

| Stamping Computer Enclosures | Stamping Computer Enclosures Surface treatment: We are capable of providing various treatments, including powder coating, anodizing, silk print... | |

| Custom Laser Welded Parts | Detail Material: Stainless Steel/Aluminum/Iron/SECC Thickness: 1.5mm Surface treatment: Spray and powder coating Process: Blanking - hydraulic f... | |

| Precision Sheet Metal Cabinets | Detail precision sheet metal cabinetis Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal drawersis one of th... | |

| Custom Aluminum Parts | As a professional CNC metal parts manufacturer, HSJ is specialized in billet aluminum parts and custom aluminum component manufacturing. Materia... | |

| Sheet Metal Cabinets | Sheet metal has the characteristics of lightweight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, a... |

Same products

| Metal Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Metal Insulated Composite Panel Systems The system is composed of fire-resistant composite metal... | |

| AluzincMg-Al-Zn Alloy Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | AluzincMg-Al-Zn Alloy Composite Panel Systems Introducing magnesium aluminum zinc composite pane... | |

| Aluminium Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Aluminium Insulated Composite Panel Systems This system features composite panels manufactured i... | |

| 3D Aluminium Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | 3D Aluminium Composite Panel Systems The 3D Aluminium Composite Panelutilizes aluminum alloy she... | |

| Calcium Silicate Board Integrated Exterior Wall Insulation | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Calcium Silicate Board Integrated Exterior Wall Insulation and Decoration Panel Leboomoffers hig... |