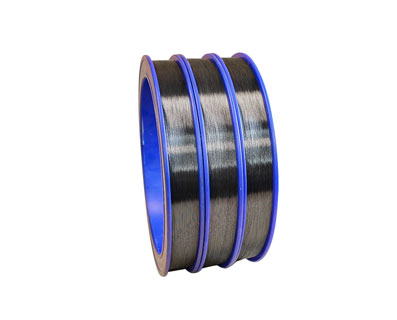

Molybdenum Metal Bar

High quality prue molybdenum bar for sale! As a typical product of the insoluble metal Mo, molybdenum bar is a rod mainly made of molybdenum. Therefore, molybdenum bar or molybdenum rod can be referred to as molybdenum bar or molybdenum rod in many cases. The purity of molybdenum bar for sale is 99.7%. Because of its good thermal, mechanical, chemical, electrical and other properties, it is widely used in smelting, power equipment and other fields. Contact our molybdenum bar supplier and get the latest molybdenum bar price!

Specification of Molybdenum Metal Bar

|

GRADE |

Mo content |

Content of added elements |

The sum of other impurity elements |

Content of each impurity element |

|||

|

Co、Mg |

La2O3 |

Si、AL、K |

Y2O3 |

||||

|

MoCo |

≥99.95 |

≤0.05 |

≤0.01 |

||||

|

MoLa |

≥99.95 |

≤0.05 |

≤0.01 |

||||

|

MoK |

≥99.95 |

≤0.05 |

≤0.01 |

||||

|

MoY |

≥99.95 |

≤0.05 |

≤0.01 |

||||

|

Mo1 |

≥99.95 |

≤0.05 |

≤0.01 |

||||

|

Mo2 |

≥99.90 |

≤0.10 |

≤0.01 |

||||

Size Specification(Unit: mm)

|

Molybdenum square bars |

Molybdenum round bar |

||

|

a |

L |

φ |

L |

|

11≤a≤17 |

≥350 |

17≤φ≤100 |

≥500 |

Application of Molybdenum Metal Bar

Conventional molybdenum strip is mainly made of molybdenum wire; High temperature molybdenum strip can be used to prepare high strength wire cutting molybdenum wire, high temperature electric heating element, electric light source material, electric vacuum device and high temperature structural parts, etc. Molybdenum strip is mainly used as an additive to improve the strength and toughness of steel at high temperature.

As one kind of molybdenum products, Molybdenum rod is used for large slab and is the raw material of molybdenum silicide heating element. Fmo-2 is used for silicon controlled wafer, molybdenum tip and other raw materials. Can also be used in powder metallurgy materials, building materials and chemical, petroleum industry. Molybdenum is one of the essential trace elements in plants and is used as trace element fertilizer in agriculture.

Application of Molybdenum Metal Bar

Production Process of Molybdenum Metal Bar

Production Process of Molybdenum Metal Bar

Production package after years of practice, we think mainly crystal bar type B molybdenum acid as by roasting process via reduction, suppression of sintered article further deep processing of raw material is better, the current domestic processing filaments article molybdenum manufacturers also continue to use this material as drawn filaments molybdenum strip of raw materials, in addition to the product shape appearance, the content of major elements, such as kalium, sodium, physical properties, such as Ratio, particle size and so on all must meet certain requirements, and maintain a relatively stable.

From the perspective of production methods, the preparation process of molybdenum strip is as follows:

molybdenite concentrate → oxidative roasting → calcining → leaching → ammonium molybdate solution → purification → neutralization crystallization → ammonium polymolybdate solution → dissolution → evaporation crystallization → ammonium secondary molybdate → calcining → molybdenum trioxide → reduction → molybdenum powder → molding sintering → molybdenum strip.

Note that ammonia should be added during leaching and dissolution; Hydrochloric acid should be added during neutralization and crystallization. The gas used in reduction is hydrogen.

Features of Molybdenum Metal Bar

From the physical and chemical properties, ordinary molybdenum strip has various advantages of metallic molybdenum, such as bright and shiny surface, high melting point, high specific gravity, high strength, large hardness, low thermal expansion coefficient, high temperature resistance, good conductivity and so on. Note: Molybdenum strips are silver in color and black when lubricant and oxide coating are retained on the surface.

In terms of appearance and shape, the molybdenum strip is rectangular and cylindrical; From the surface state, molybdenum strip can be alkali washed, polished, polished and polished; From the point of use, molybdenum bar can be divided into conventional molybdenum bar, high temperature molybdenum bar and steel making molybdenum bar.

There are many refractory metal suppliers, but we are one of the best choices for you.

Send product request

Other supplier products

| Tungsten Sheet | Tungsten content ≥99.95% total of other elements ≤0.05% content of a single element ≤0.01%. Tungsten sheet metalApplication fields: ... | |

| Tungsten Wire | As one of the most professional tungsten wire suppliers and tungsten wire manufacturersin China, HSG provides pure tungsten wire wholesale. Tungste... | |

| Refractory Metals | As one of the reliable refractory metal suppliers, Huasheng Metal are keeping a large and comprehensive inventory of the highest quality in form of... | |

| Ferro Molybdenum | Ferro molybdenum is a ferroalloy composed of molybdenum and iron, generally containing 50-60% molybdenum, with a high ferro molybdenum melting poin... | |

| Ferro Molybdenum | Ferro Molybdenum Ferro molybdenum is a ferroalloy composed of molybdenum and iron, generally containing 50-60% molybdenum, with a high ferro molyb... |

Same products

| Metal Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Metal Insulated Composite Panel Systems The system is composed of fire-resistant composite metal... | |

| AluzincMg-Al-Zn Alloy Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | AluzincMg-Al-Zn Alloy Composite Panel Systems Introducing magnesium aluminum zinc composite pane... | |

| Aluminium Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Aluminium Insulated Composite Panel Systems This system features composite panels manufactured i... | |

| 3D Aluminium Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | 3D Aluminium Composite Panel Systems The 3D Aluminium Composite Panelutilizes aluminum alloy she... | |

| Calcium Silicate Board Integrated Exterior Wall Insulation | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Calcium Silicate Board Integrated Exterior Wall Insulation and Decoration Panel Leboomoffers hig... |