Ferro Alloy

Ferro alloys meaning

Ferroalloy is a general term for alloys composed of iron and silicon, manganese, chromium, titanium, tungsten, molybdenum, tantalum, niobium and other elements. It cannot be used to cast parts directly, but only as a reducing agent or additive in the casting or steelmaking process. Ferro alloys commonly used in casting are ferro tungsten, ferromolybdenum, ferrovanadium, ferroniobium,ferrosilicon and ferromanganese. Ferroalloy is one of the essential raw materials in iron and steel industry and casting industry. Its main uses: one is as a deoxidizer, remove excess oxygen in liquid steel; The other is as alloying element additive to improve the quality and performance of steel.

As one of the professional ferro alloys traders, HSG ferroalloy company offers varioustypes of ferro alloys. We also offer our customers a good ferro alloys price. Contact us and get affordable bulk ferro alloys price!

Ferro Alloys Meaning and Definition

Ferro alloys are a category of alloys that are primarily composed of iron, with other elements added in varying quantities to achieve specific properties and characteristics. These alloys are used in a wide range of industrial applications, including steelmaking, casting, and welding. Ferro alloys are typically produced by smelting or melting iron alloyed with other metals in an electric arc furnace. Common ferro alloys include ferrosilicon, ferromanganese, ferrochrome, ferrotungsten, ferrovanadium, ferroboron, ferrophosphorus, and ferrosilicon magnesium. The properties of these alloys can be tailored to meet specific application requirements by adjusting the ratios of the alloying elements.

Huasheng Metal, as one of the most professional refractory metal suppliers in China, know clearly about ferro alloys types. We offer differnt types of ferro alloys for specific applications. If you have any doubts about ferro alloys and not sure about what ferro alloys types to choose, please feel free to contact us.

Ferro Alloy Plant Process

There are many production methods of ferroalloys, most of ferro alloy plant processes are produced by pyrometallurgy. According to the smelting equipment used, operation method and heat source, it is mainly divided into the following categories:

According to the refractory metal suppliers production equipment, it can be divided into blast furnace method, electric furnace method, out-of-furnace method, converter method and vacuum resistance furnace method.

According to the different heat sources, it is divided into carbothermal method, electrothermal method, electrosilicon thermal method and metal thermal method.

According to the different production and operation process characteristics, it is divided into flux method, solvent-free method, slag-free method, slag-containing method and continuous and batch smelting methods.

Benefits of Using Ferro Alloy

01

Deoxidizers

Ferromanganese and ferrosilicon are the most widely used deoxidizers in steelmaking. Strong deoxidizers are aluminum (aluminum iron), calcium silicon, silicon zirconium, etc. (see deoxygenation of steel).

02

Alloy Additives

The common varieties used as alloy additives are: ferromanganese, ferrochrome, ferrosilicon, ferrotungsten, ferromolybdenum, ferrovanadium, ferrotitanium, nickel-iron, niobium (tantalum) iron, rare earth iron alloy, ferroboron, ferrophosphorus, etc.

03

Inoculant

Ferroalloys are added into molten iron before casting to improve the crystalline structure of cast iron. In addition, it is also used as a reducing agent for the production of other ferroalloys and non-ferrous metals by metal thermal reduction. Alloy additives for non-ferrous alloys; Small amounts are also used in the chemical industry and other industries.

Send product request

Other supplier products

| Refractory Metals | Refractory Metals As one of the reliable refractory metal suppliers, Huasheng Metal are keeping a large and comprehensive inventory of the highest... | |

| Ferro Vanadium | Ferro Vanadium HSG Metal has ferro vanadiumfor sale! Get the latest ferro vanadium price! Ferro Vanadium is typically manufactured from Vanadiu... | |

| Molybdenum Tube | Molybdenum tubehas high melting point, high strength, good thermal conductivity, high temperature resistance and corrosion resistance; Can be us... | |

| Niobium Tube | Niobium and niobium alloy tubes, rods and wires are widely used in chemistry, electronics, aviation and aerospace because of their high melting poi... | |

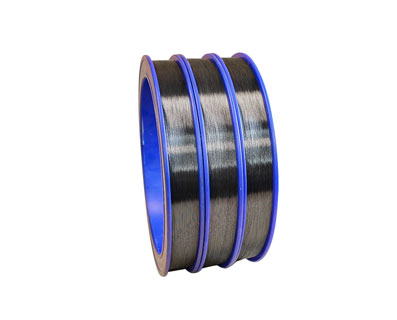

| Tungsten Wire | As one of the most professional tungsten wire suppliers and tungsten wire manufacturersin China, HSG provides pure tungsten wire wholesale. Tungste... |

Same products

| Metal Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Metal Insulated Composite Panel Systems The system is composed of fire-resistant composite metal... | |

| AluzincMg-Al-Zn Alloy Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | AluzincMg-Al-Zn Alloy Composite Panel Systems Introducing magnesium aluminum zinc composite pane... | |

| Aluminium Insulated Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Aluminium Insulated Composite Panel Systems This system features composite panels manufactured i... | |

| 3D Aluminium Composite Panel Systems | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | 3D Aluminium Composite Panel Systems The 3D Aluminium Composite Panelutilizes aluminum alloy she... | |

| Calcium Silicate Board Integrated Exterior Wall Insulation | Seller: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Calcium Silicate Board Integrated Exterior Wall Insulation and Decoration Panel Leboomoffers hig... |