Pipe Welding & Cutting Machines

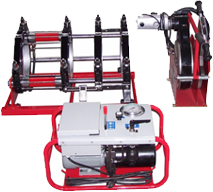

Butt Welding Machine is suitable for butt fusion of plastic pipes made of PE, PP and PVDF material. It has a Certification of CE and ISO. The Color is red or customized. Applicable Materials: PE, HDPE, PP, PVDF, PPR, PB.

Pipe welding & cutting machines are necessary for metal pipe procedure. Plaswelding is a professional industrial welding machine manufacturer & supplier that can provide various kinds of reliable welding and cutting machines. As one of the leading plastic welding machine suppliersin China, we have our own factory and own a wide range of pipe welding machines for sale including plastic pipe welders, fusing welding equipment for pipes, etc. If you want to get more information, please contact us now and get an attractive price.

What plastic is used for types of plastic welding?

The machine is used to weld pipes made from PE, PP, PVDF and can not be used to weld material without description, otherwise the machine may be damaged.

Or some accident may be resulted in.

PE material

Polyethylene is a thermoplastic resin prepared by polymerization of ethylene. In industry, it also includes the copolymer of ethylene and a small amount of α-olefin. Polyethylene odorless, non-toxic, feel like wax, has excellent low temperature resistance, good chemical stability, can withstand the erosion of most acids and bases. Insoluble in general solvents at room temperature, low water absorption and excellent electrical insulation.

PP material

Polypropylene is a polymer formed by addition polymerization of propylene. It is a white waxy material with a transparent and light appearance. The melting point is 189 ℃ and the temperature range is-30mm 140 ℃. It is widely used in the production of fiber products such as clothing, blankets, medical devices, automobiles, chemical containers, etc., as well as food and drug packaging.

PVDF material

PVDF, also known as fluoroplastic, is a kind of high-crystallization, high-performance geothermal plastic, which is suitable for a wide range of temperatures and provides full security for high-temperature applications; it has good anti-ultraviolet properties, even if installed outdoors, ultraviolet radiation does not affect its life and material properties at all.

How to use plastic pipe weldingmachine

(1) Before welding, firstly, check if the material, diameter and wall thickness are the required ones. Secondly check if there are scratches or fissures on the surface of pipes/fittings.

(2) Clean the inside and outside surface of pipe ends to be welded.

(3) Place the pipes/fittings in inserts of frame. The pipe out of the basic frame should be supported to the same central axial of clamps. Fasten the screws of clamps to fix the pipes/fittings.

(4) Test the drag pressure: open the pressure regulation valve completely, lock the swing check valve tightly and then push forward the direction valve meanwhile adjust the pressure regulation valve.

(5) Open the pressure regulation valve completely, lock the swing check valve tightly and then push forward the direction valve meanwhile adjust the pressure regulation valve to set the system pressure equals to drag pressure add butting pressure.

(6) Separate the pipes/fittings ends after turning swing check valve in anti-clockwise direction to relief the pressure to lowest.

(7) Close the pipes/fitting ends and check the alignment of them. The maximal misalignment should not exceed 10% of the wall thickness, and it could be improved by loosening or tightening the screws of clamps.

(8)Clear the dust or slit on the surface of heating plate, and put the heating plate between the pipe ends after it reaches required temperature. Close the pipes/fittings end.

(9) Turn swing check valve anti-clockwise to reduce the pressure (not more than drag pressure) and turn swing check valve in clockwise direction to the end. Press the button “T2”.

(10) Open the frame and take out the heating plate and close two melting ends as quickly as possible.

(11)Keep the bar of direction valve on the close position for 2~3 minutes, put the bar of direction valve on middle position and press the button (“T5”) to count cooling time until it is over.

Types of Pipe Welding & Cutting Machines for Sale

Pipe welding & cutting machines are necessary for metal pipe procedure. Plaswelding is a professional industrial welding machine manufacturer & supplier that can provide various kinds of reliable welding and cutting machines.

Butt Welding Machine

HYDRAULIC butt welding machines are suitable for PE & PP pipes and fittings on the building site and in factory.

CNC Welding Machine

CNC Automatic Butt Welding Machine is suitable for HDPE/PP pipes and fittings of gas pipe line.

Workshop Welding Machine

LHJ serial workshop welding machine can fabricate the equal welding fittings in PE or other plastic.

Saddle Welding Machine

Saddle welding machine can fabricate the reducing tee welding fittings in PE, PP or other thermoplastic material.

Electric Welding Equipment

Electric welding machine is a special equipment for PE pipe electric melting welding.

Automatic Pipe Saw Machine

Hydraulic operated pipe saws, specially used for the preparation of pipe segments in PE, PP and so on.

Arched Surface Pipe Saw

Arched surface pipe saw can cut branch pipe with specific radian while fabricating the welding fittings in PE, PP, etc.

What plastic is used for types of plastic welding?

The machine is used to weld pipes made from PE, PP, PVDF and can not be used to weld material without description, otherwise the machine may be damaged.

Or some accident may be resulted in.

PE material

Polyethylene is a thermoplastic resin prepared by polymerization of ethylene. In industry, it also includes the copolymer of ethylene and a small amount of α-olefin. Polyethylene odorless, non-toxic, feel like wax, has excellent low temperature resistance, good chemical stability, can withstand the erosion of most acids and bases. Insoluble in general solvents at room temperature, low water absorption and excellent electrical insulation.

PP material

Polypropylene is a polymer formed by addition polymerization of propylene. It is a white waxy material with a transparent and light appearance. The melting point is 189 ℃ and the temperature range is-30mm 140 ℃. It is widely used in the production of fiber products such as clothing, blankets, medical devices, automobiles, chemical containers, etc., as well as food and drug packaging.

PVDF material

PVDF, also known as fluoroplastic, is a kind of high-crystallization, high-performance geothermal plastic, which is suitable for a wide range of temperatures and provides full security for high-temperature applications; it has good anti-ultraviolet properties, even if installed outdoors, ultraviolet radiation does not affect its life and material properties at all.

How to use welding machine for plastic pipe

(1) Before welding, firstly, check if the material, diameter and wall thickness are the required ones. Secondly check if there are scratches or fissures on the surface of pipes/fittings.

(2) Clean the inside and outside surface of pipe ends to be welded.

(3) Place the pipes/fittings in inserts of frame. The pipe out of the basic frame should be supported to the same central axial of clamps. Fasten the screws of clamps to fix the pipes/fittings.

(4) Test the drag pressure: open the pressure regulation valve completely, lock the swing check valve tightly and then push forward the direction valve meanwhile adjust the pressure regulation valve.

(5) Open the pressure regulation valve completely, lock the swing check valve tightly and then push forward the direction valve meanwhile adjust the pressure regulation valve to set the system pressure equals to drag pressure add butting pressure.

(6) Separate the pipes/fittings ends after turning swing check valve in anti-clockwise direction to relief the pressure to lowest.

(7) Close the pipes/fitting ends and check the alignment of them. The maximal misalignment should not exceed 10% of the wall thickness, and it could be improved by loosening or tightening the screws of clamps.

(8)Clear the dust or slit on the surface of heating plate, and put the heating plate between the pipe ends after it reaches required temperature. Close the pipes/fittings end.

(9) Turn swing check valve anti-clockwise to reduce the pressure (not more than drag pressure) and turn swing check valve in clockwise direction to the end. Press the button “T2”.

(10) Open the frame and take out the heating plate and close two melting ends as quickly as possible.

(11)Keep the bar of direction valve on the close position for 2~3 minutes, put the bar of direction valve on middle position and press the button (“T5”) to count cooling time until it is over.

Competitive Plaswelding Pipe Welding Machine

Specializing in the production of supply automatic docking hot melt welding machine, semi-automatic docking hot melt welding machine, HDPE butt fusion welding machines,PE butt welding machine,large diameter plastic pipe socket welding machine.

As aprofessional pipe cutting machine manufacturer, we provide pe pipe fusion welding machine, ppr fusion welding machine, industrial welding machine for sale, polypropylene pipe welding, plastic welding machine for sale, china plastic pipe welding machineand etc. Want to knowplastic welding machine priceor more? Contact us.

Send product request

Other supplier products

| Features of Pipe Saw | Hydraulic operated pipe saws, especially used for the preparation of pipe segments in PE, PP and other thermoplastic materials for the production o... | |

| CNC Welding Machine | Features of Automatic Tube Welding Machine CNC Automatic Butt Welding Machine is suitable for HDPE/PP pipes and fittings of gas pipeline. The heat... | |

| Gas/Oil | Wuxi Plaswelding Machinery Co., Ltd. is one of theprofessional PE pipe welding machine manufacturers, HDPE butt fusion welding machine, PVC pipe we... | |

| Hydraulic Butt Welding Machine | Features of lRemovable PTFE coated heating plate with high accurate temperature control system; lElectrical planning tool; lBe made of lightw... | |

| Automatic Pipe Saw Machine | Features of Pipe Cutting Saw Hydraulic operated pipe band sawespecially used for the preparation of pipe segments in PE, PP and other thermoplasti... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |