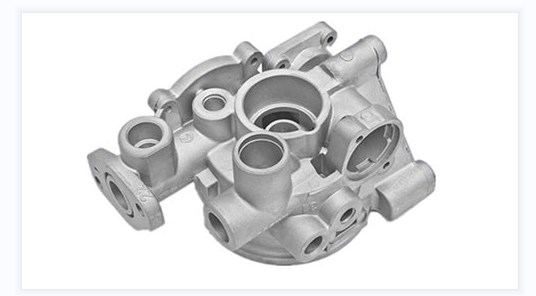

Aluminum Die Casting Mold

Aluminum High Pressure Die Casting Mold

When working at high or low temperatures, they also maintain good mechanical properties and have good corrosion resistance. properties and antioxidant properties. Die castings are widely used in construction, hardware, equipment, machine tools, ships, aerospace, automobiles, electronics, computers, electrical appliances, lamps, and many other fields.

Aluminum Die Casting Applications

Aluminium die casting mold is used frequently in the automotive industry as a durable, lightweight alternative to steel and iron. Its electrical and thermal conductivity properties make it well suited for the telecommunications and computer industries. Its lightweight makes it an excellent choice for portable applications.

Aluminum Die Casting Capabilities

Aluminum Die Casting Mold Specification

Material Capabilities Aluminum alloy, zinc alloy

Molding Processes die casting

Machine Size/ Clamping Force 100 - 800 Tons

Number of Cavities One or Multiple

Production Volume 5,000 units up to 100,000+

Manufacture time (day) 30-45 days

Quality Certifications ISO 9001:2015

Benefits Of Aluminum Die Casting

It can manufacture metal parts with complex shapes, clear outlines, thin walls, and deep cavities. Because molten metal maintains high fluidity at high pressure and high speed, metal parts that are difficult to machine by other processes can be obtained.

The material utilization rate is high. Due to the high precision of die castings, they can be assembled and used with only a small amount of machining.

High production efficiency. Due to high-speed filling, the filling time is short, the metal industry solidifies rapidly, and the die-casting operation cycle speed is fast.

We Provide Full Service For Die Casting Projects

Green Vitality custom die casting solutions include:

DFM and Design optimization Suggestions

Mold flow simulation analysis

Rapid prototyping

Custom Die Casting Tooling design

Die-casting

CNC and conventional machining

Surface finishing

Coatings, plating, painting

Assembly

Testing & Reports

Packaging &Delivery

We can offer kinds of injection molding dies for sale, if you have needs, please contact us.

If you want to know more kinds of injection molded parts, please visit our website.

Send product request

Other supplier products

| Game Controller Mold | To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time wil... | |

| Game Controller Mold | Game Controller Molds To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, mach... | |

| Medical Plastic Injection Mold | Provide complete solutions from product design/mold manufacturing/injection mass production. Provide professional medical consumables and medical ... | |

| Industrial Plastic Injection Mold | Plastic Mould Industry The industrial plastic injection moldis replacing metal products in many fields of industrial applications to meet the requ... | |

| Medical Test Tube Mold | As a container for nucleic acid detection, there is a huge amount of consumption every day in the world. How to produce with high efficiency and hi... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |