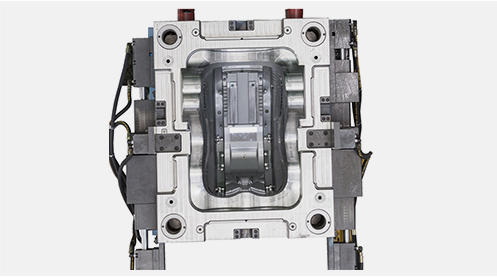

Car Seat Mould for Kids

Child safety mouldy car seatsare seats specially designed to protect children from injury or death in a collision. The main structure of the child safety seat is a plasticpart produced by the child safety car seat mould , and there are also some metal parts to fix or support these plastic parts. The product design and mold design of the child safety car seat mold are the most important. For example, the thickness and design of the ribs of the plastic parts will lead to the surface of the plastic parts with sink marks, and the requirements for steel selection and mold processing equipment are also very high. Green Vitality provides professional solutions to customers for each project.

High-quality Injection Mold for Child Safety Seat

The production output of child safety seat mold is very large, so high-quality child safety chair mold is very important. An efficient mold cooling system can shorten the injection cycle and save more processing costs and time. We are very concerned about the mold cooling system and mold production stability. Our goal is to ensure customers to run as little mold repair work as possible, and be able to perform mass production efficiently and stably.

Basic Information for Child Safety Seat Mold

Specifications of Green Vitality Injection Mould

Description Child safety seat mold

Plastic material PP

Mould dimension(mm) 1600*1000*980

Mould weight (T) 10T

Mould cavity&core steel P20

Nos of Cavity 1*1

Manufacture time (day) 60 days

Mould life ≥500000

Molding cycle (S) 100 S

Cooling line connector type DME NS350 SERIES quick coupling,

Mold Characteristics excellent cooling system design

Short cycle time

Advantage of Green Vitality Injection Mould

We have more than 20 years of experience in plastic injection mold manufacturing, rich experience in Child Safety Seat mold.

We have advanced process and inspection equipment and regular investment in leading-edge equipment.

As an injection molding supplier, we can participate in and assist customers from the initial product design and development to the entire stage of mold making and product production and delivery.

We provide a perfect project Management System.

We provide innovative solutions based on varied industry experience.

We guarantee our molds for the life of your project.

How to Choose A Suitable Child Safety Seat?

Choose a child safety seat that meets or exceeds the safety standards for motor vehicles.

Before using the child safety seat for the first time, learn how to install the seat and use the seat belt.

If you know that the safety seat has had an accident, don't use it. It may be damaged in ways you can't see.

Do not use child safety seats with missing parts or without production date and model number.

Check the recommended "validity period" of the safety seat. If there is no instruction manual, please do not use the seat.

If the safety seat has cracks or other signs of wear, do not use it.

More kinds of plastic molded parts, please visit our website.

Send product request

Other supplier products

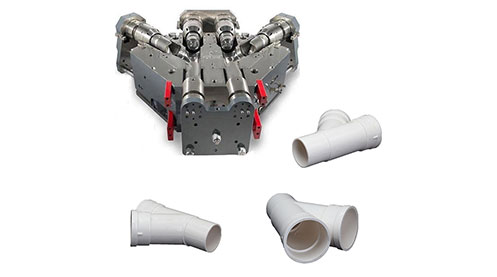

| PVC Pipe Fitting Mould | PVC fitting mould is playing an important role in the pipeline systems, they are used for connection, control, direction change, diversion, sealing... | |

| Keyboard Mould | Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard key mol... | |

| LCD TV Mould | TV screen frame mold is used to produce TV screen frames, it should be strong and assembly well with the screen. It has an undercut to lock the scr... | |

| Industrial Plastic Injection Mold | Plastic Mould Industry The industrial plastic injection moldis replacing metal products in many fields of industrial applications to meet the requ... | |

| Game Controller Mold | Game Controller Molds To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, mach... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |