General Plastic Extrusion Profiles

A die or group of dies are used to heat raw plastic material during the plastic extrusion manufacturing process and shape it into a continuous profile or length. Flexible plastic goods called general plastic extrusion profilesare employed in a wide range of tasks like sealing, edging, decorating, and reinforcing. These extruded plastic profilesfrom plastic profile manufacturerare frequently constructed from popular plastic materials like PVC, PE, PP, or ABS, and they come in a variety of forms including tubes, channels, rods, strips, and sheets. Because to their great strength, endurance, and resistance to chemicals and the elements, they offer a practical and affordable option for a variety of sectors.

Types of General Extruded Plastic Shapes

Custom ABS Extrusions Profile

ABS extrusions profile, known for its strength and impact resistance, is widely used in the construction and automotive industries.

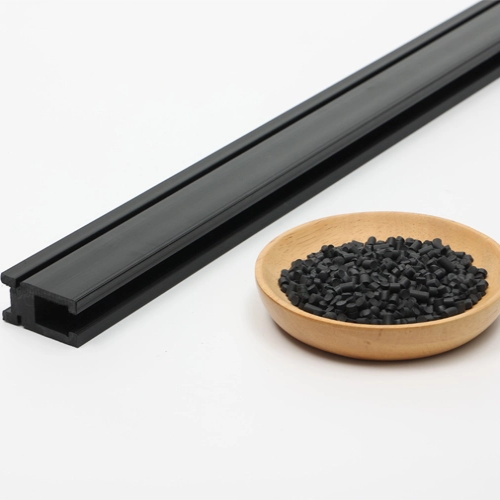

Custom PP/PE Extrusion Profile

PP (polypropylene) and PE (polyethylene) extrusion profiles are highly durable and chemical-resistant, making them ideal for the packaging, storage, and transportation industries. These profiles can be customized to meet specific project requirements and come in a variety of shapes, such as tubes, channels, rods, strips, and sheets. Overall, general plastic extrusion profiles offer versatile solutions for many applications in various industries.

How General Plastic Extrusion Profiles Are Made?

Raw plastic material is heated and shaped into an uninterrupted profile or length during the profile custom extrusion process. Plastic powder or pellets are first melted, then fed into a barrel where they are pushed at a high pressure through a die or series of dies. A water bath or other cooling system is used to drive plastic material through a die that has been molded to the required profile. The material is then trimmed to the required length and form after being extruded. For usage in several applications across numerous sectors, extrusion profiles may be made in a range of forms and sizes.

As one of extrusion profile manufacturers, we can offer sorts of related products for sale, anything you need, please contact us.

Send product request

Other supplier products

| Custom PP/PE Extrusion Profile | PPextrusion/PE extrusion profile is the process of producing custom extruded products using Polypropylene (PP) or Polyethylene (PE) material. PP/PE... | |

| Custom Mirror Surface Profiles | Custom mirror frame profilesare used in applications where a reflective surface is desired for aesthetic or functional purposes. These profiles are... | |

| Soft PVC Extrusion Profile | Soft PVC extrusionprofiles have a flexible and rubber-like texture that makes them ideal for applications requiring cushioning, sealing, or impact ... | |

| Customized Plastic Extrusion Profiles | custom plastic profile extrusion custom profile plastics oem extrusion profile/ custom extruded rubber profiles custom plastic extrusions manufa... | |

| Soft PVC Extrusion Profile | Soft PVCextrusion profiles have a flexible and rubber-like texture that makes them ideal for applications requiring cushioning, sealing, or impact ... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |