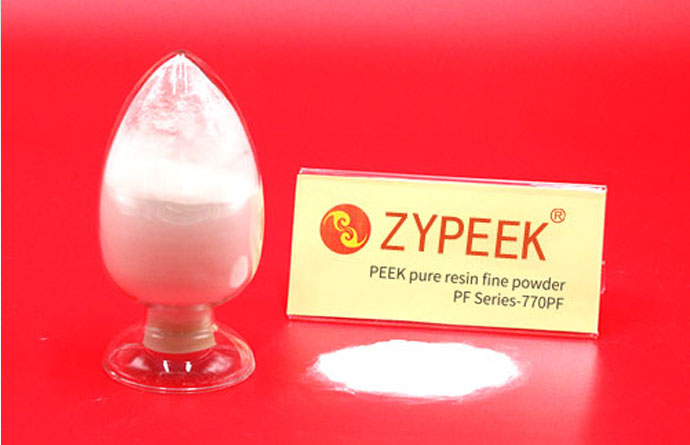

Natural PEEK Raw Material Applications

Natural PEEK Plastic Applications

PEEK polyetheretherketone raw material has excellent comprehensive properties and can replace traditional materials such as metals and ceramics in many special fields. PEEK has applications in mechanical engineering, aerospace, automotive industry, medical, electrical and electronics, pharmaceutical, and food processing industries, of which the transportation industry (including automobiles and aviation), machinery industry, and electrical and electronic industry account for the highest proportion of applications.

What Is Peek Material?

Peek (polyetheretherketone) is a high-performance engineering thermoplastic that is used in a wide range of industries including aerospace, automotive, medical devices and electronics. It is a semi-crystalline thermoplastic that offers high temperature, chemical, wear and fatigue resistance combined with excellent mechanical properties.

The properties of Peek plastic include high strength, stiffness, good dimensional stability, excellent creep resistance and low friction coefficient. It is also an excellent electrical insulator, with good resistance to radiation and excellent resistance to hydrolysis.

Peek is often used as a substitute for metals due to its high strength to weight ratio and because of its ability to be easily machined and molded into complex shapes. It is also used in healthcare applications due to its biocompatibility, resistance to sterilization and low corrosion.

Peek is available in different grades based on its intended use. Unfilled Peek is the most commonly used grade and is ideal for applications in which high mechanical and wear resistance is required. Other grades of Peek include glass-filled, carbon-filled and mineral-filled Peek, each designed to meet specific properties and applications.

Overall, Peek is a versatile material that can be used in various industrial applications that require high-performance, lightweight materials that exhibit exceptional mechanical and thermal properties.

What Is Peek Plastic Used For?

Peek (Polyetheretherketone) plastic is a high-performance thermoplastic used for a wide range of industrial applications. Its unique combination of properties makes it ideal for use in high-demanding applications where durability and strength are critical factors. Here are some of the most common uses of Peek plastic:

Aerospace Industry: Peek plastic is used in the aerospace industry for parts that require high-temperature resistance, such as engine components, structural parts, and electrical components.

Medical Industry: Peek plastic partsare used in the medical industry for applications such as dental implants, orthopedic implants, and surgical instruments. It is biocompatible, lightweight, and has excellent wear resistance.

Automotive Industry: Peek plastic is used in the automotive industry for parts such as gears, pumps, and bearings that are subjected to high-temperature and high-stress applications.

Electrical and Electronics: Peek plastic is used in the electrical and electronic industry for parts such as connectors, insulation, and components that require high-temperature resistance, low water absorption, and excellent dimensional stability.

Oil and Gas Industry: Peek plastic materialis used in the oil and gas industry for parts such as valve seats, seals, and connectors that require resistance to high pressure, high temperature, and corrosive environments.

Overall, applications of peekare numerous in the industrial sector, where high-performance, lightweight, and durable materials are required.

Send product request

Other supplier products

| Compression Molding Peek | Compression Molding PEEK PEEK has excellent corrosion resistance, radiation resistance, high-temperature resistance, low-temperature resistance,... | |

| PEEK Seal Material in Mechanical | PEEK Seal Materialin Mechanical PEEK is a kind of mateiral with both rigidity and toughness, excellent mechanical properties, wear resistance, s... | |

| CA Series-550CA30 PEEK Carbon Fiber Reinforcement | CA Series-550CA30 PEEK carbon fiberreinforcement is a 30% carbon fiber reinforced PEEK plastic material, the addition of carbon fiber significantly... | |

| PEEK Valve in Home Appliances | PEEK Valvein Home Appliances PEEK has good wear resistance, self-lubrication, non-toxicity, high-temperature resistance, low density, and can de... | |

| ZYPEEK PEEK Raw Materials | PEEKthermoplastic polymerraw material is a kind of semicrystalline aromatic polvmer and its main chain of macromole is consist of arvl. ketone, and... |

Same products

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | Seller: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | Seller: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |