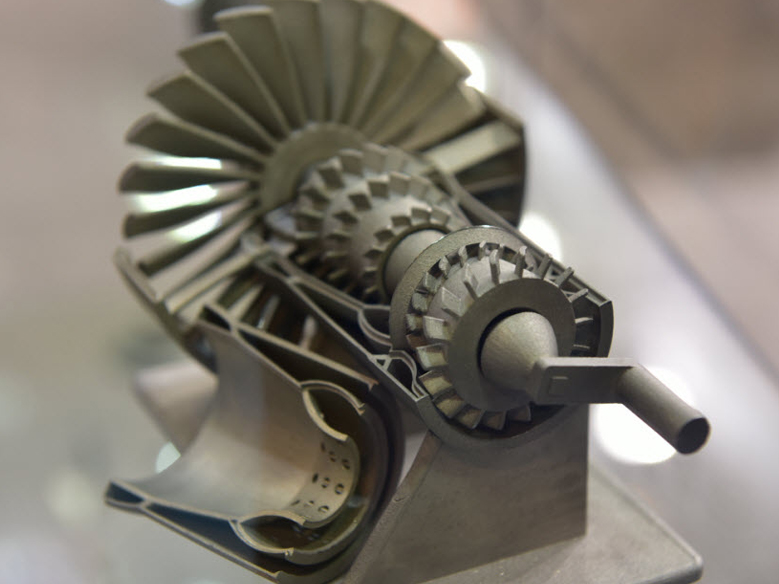

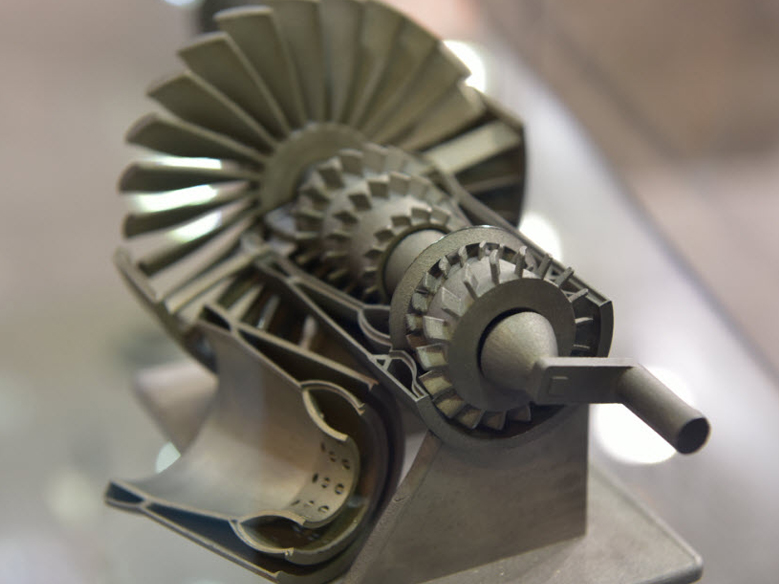

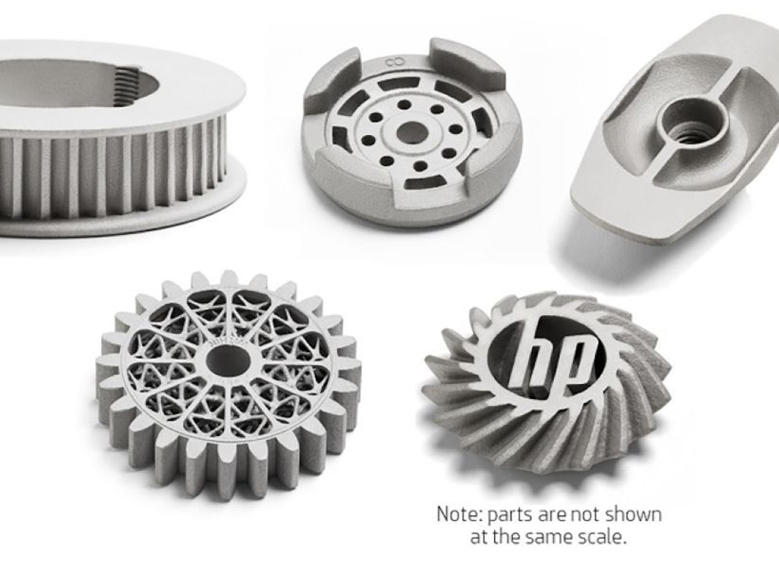

SLS Nylon Printing

3D printed nylon parts can be used for product verification or directly used as functional products. The product is 3d prototype printing with light weight and shorter production cycle. It has great application space in automobile, aerospace, art creation, medical treatment and other fields. SLS products have many surface pores after forming, and the surface roughness is about Ra12.5. The surface roughness, finish and coloring of SLS products cannot meet the requirements of practical use.

SLS Nylon Printing Material Properties

Nylon material, as a classic material, is famous for its excellent durability, high specific strength, high toughness, low wear resistance and corrosion resistance, and has been widely used in the field of processing and manufacturing.

Nylon is a name for Polyamide fiber. It's called PA . For some users who often use PLA, PLA printing is flexible, suitable for many occasions, and It has the general strength required for ordinary occasions, but when it is used in professional occasions, it will find it is not suitable. PLA printed parts cannot be exposed to sunlight for long periods of time and are not suitable for applications above 100°C. If ABS is used for 3D printing, it will be found that it is more durable than PLA. However, 3D printed ABS parts are usually not as strong as injection parts, and printed parts are generally not strong enough due to the adhesion between layers.

Nylon consumable is a kind of high strength, very durable 3D printing consumable. Very tough, at the same time good adhesion between layers, more solid than ABS consumables.

Mechanical Properties of SLS Nylon 12 Printing

Nylon has excellent mechanical properties. Its tensile strength, compressive strength, impact strength, rigidity and wear resistance are better, suitable for manufacturing some need to high strength, high toughness products. However, its mechanical properties are greatly affected by temperature and humidity, and its tensile strength decreases with the increase of temperature and humidity. Nylon has good impact properties. It increases with the increase of temperature and water absorption, and hardness decreases with the increase of water content.

Now the price of nylon 12 sls powder is reasonable, if you have needs, please contact us.

As one of the rapid cnc prototyping services, Medical equipment are large, CNC model and small batch production of vacuum casting is very suitable for medical production and testing.

Other supplier products

|

|

Titanium 3D Printing Service |

Titanium 3d printing service for Titanium alloy parts has very high strength, precise dimensions, and their mechanical properties are better than t... |

|

|

Titanium 3D Printing Service |

Titanium 3d printing servicefor Titanium alloy parts has very high strength, precise dimensions, and their mechanical properties are better than th... |

|

|

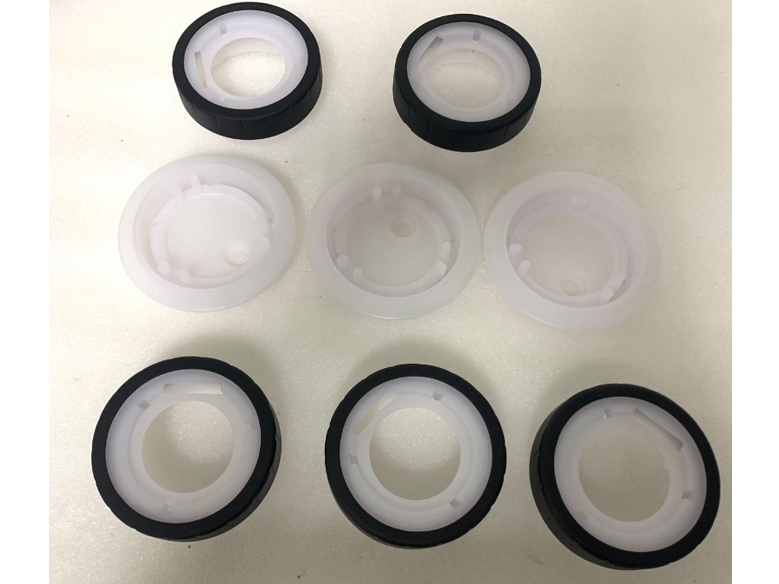

Vacuum Casting Plastic |

Vacuum casting process: free mold opening, low production cost, forming speed, high processing accuracy, support small batch customization and othe... |

|

|

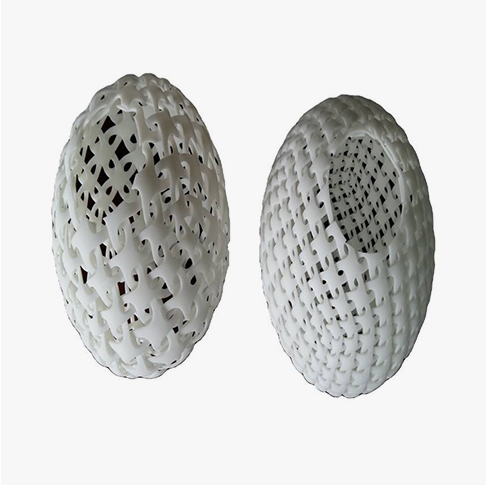

SLA Plastic 3D Printing |

SLA printingis focused on the surface of a light cured material, which is solidified from point to line and line to surface. SLA printing of SLA 3d... |

|

|

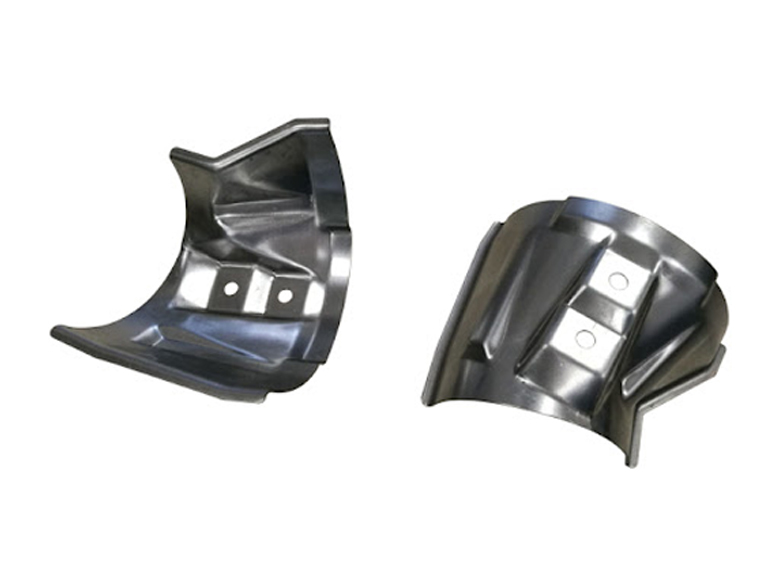

Stamped Sheet Metal Parts |

Stamped Sheet MetalParts

Proto-mold purchased advanced large laser cutting machine 3 sets, Amada precision CNC bending machine 15 sets, heavy oil ... |

All supplier products

Same products