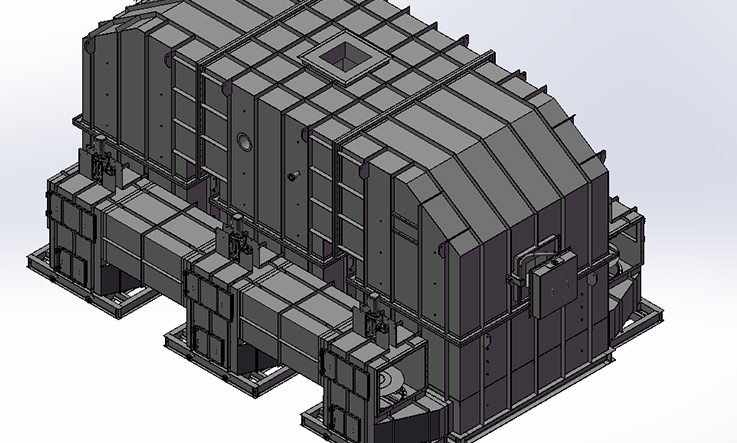

RYYT 452 Series Metal Decorating Machine

RYYT 452 series is the market and technology leader in the field of metal decorating presses. RYYT 452 series provides a high-performance metal printing solution and excellent print quality. It is an automatic offset printing machine with low make-ready times and is easy to operate. RYYT 452 series include 1-color, 2-color , 3-colour, 4-colour , 5-color, 6-color, 8-colour, multi color printing machineand we can provide 1-color, 2-color, 3-colour, 4-colour, 5-color, 6-color, 8-colour, multicolor printing machineat a suitable price.

RYYT 452 Series multicolor printing pressSpecifications

|

CONFIGURATIONS |

RYYT1452W/1-COLOR |

RYYT2452/2-COLOR |

RYYT3452/3-COLOR |

|

Maximum sheet size |

1145×950mm |

1145×950mm |

1145×950mm |

|

Minimum sheet size standard |

712×510mm |

712×510mm |

712×510mm |

|

Sheet thickness standard |

|||

|

Maximum printing area |

1135×945mm |

1135×945mm |

1135×945mm |

|

Size of printing plate |

1160×1040×0.3mm |

1160×1040×0.3mm |

1160×1040×0.3mm |

|

Size of pre-bar blanket |

1175×1135×1.9mm |

1175×1135×1.9mm |

1175×1135×1.9mm |

|

Gripper margin |

3-5mm |

3-5mm |

3-5mm |

|

Maximum mechanical speed |

5000 sheets/hrMaximum printing speed depending upon printing shop conditions and ingoing material quality |

||

|

Height of infeed table |

916mm |

916mm |

916mm |

|

Maximum weight of feeder pile |

|||

|

Power of main motor |

15 kw |

15kw+15kw |

15kw+15kw+15kw |

|

Capacity of air pump |

80+100(m³/hr) |

80+100(m³/hr) |

80+100(m³/hr) |

|

Dimension of machine(LxWxH) Length without inspection table |

6850x3700x2460mm |

10750x3700x2460mm |

14750x3700x2460mm |

|

Total connected load of machine without dryers |

36kw |

56kw |

76kw |

|

Running pressing of air cylinder |

|||

|

Compressed air |

≥140m³/h |

||

RYYT 452 Series Main Technical Performance

Three printing cylinders are arranged vertically for easy operation;

Quick gripper for printing plate and rubber cloth to reduce lead time;

Drive system of ink/water supply can be separated from the main motor to avoid dry abrasion of the rubber roller;

Advanced structure for dynamic pressure adjustment of water/ink roller makes easy operation;

Automatic adjustment of synchronization between feeder and main motor by easy operation of push button;

The shaft-less drive is used. Four printing couples are controlled by individual motor so they are independent.

The synchronized optic cable between printing couples, through the virtual main axis as reference, makes the four units quite synchronized.

Main drive device with simple structure has only one communication bus to connect PLC and is easy for service;

All cylinders/rollers and delivery device and double sheet ejector are coupled pneumatically featuring simple structure and easy operation;

Water/ink duct rollers are controlled separately by frequency converter for continuous speed change, and are synchronized/traced with main motor;

Reasonable and advanced arrangement of china offset printing machine water/ink rollers guarantees printing quality;

All three big cylinders use advanced high precision bearing support to ensure quality printing;

Hard lining structure ensures solid screen dot;

High point closing of jaws with strong gripping force and reliable transfer;

Sheet transfer by imported electronic device and standard air cylinder features simple structure and accurate transfer;

The stock lift mechanism is operated by worm wheel and chain wheel with strong load capability and without slip;

A No-sheet detector for stock controls the air pump operation and holds back the stock lift.

RUIYUAN, as one of the mostexcellent offset printing machine manufacturers in china, offers a wide range of offset machinefor you to choose from.

Send product request

Other supplier products

| CTP Computer to Plate Printing Machine | CTP (computer to plate ctp) refers To Computer direct Plate making, which uses laser scanning To record digital page information on the Plate, and ... | |

| Regenerative Thermal Oxidizer (RTO) | Regenerative Thermal Oxidizer (RTO) produced by RUIYUAN uses ceramic media to recover upwards of 97% of the available energy and is widely consider... | |

| Drying | The drying systems are used at the end of the metal printing pressand coating production lines in order to improve the print quality and yield. The... | |

| Metal Printing & Coating Machines And System Automation Solution | RUIYUAN has been a designer and manufacturer of metal printing and coating equipment for over 20 years. we committed to Manufacture Top World Class... | |

| Metal Coating Machine | Fully automatic metal coating is the essential process for anti-rust and brightness effect before and after printing for metal sheets made of tinpl... |

Same products

| Vacuum Casting Plastic | Seller: Industry Proto-mold Limited | Vacuum casting process: free mold opening, low production cost, forming speed, high processing ac... | |

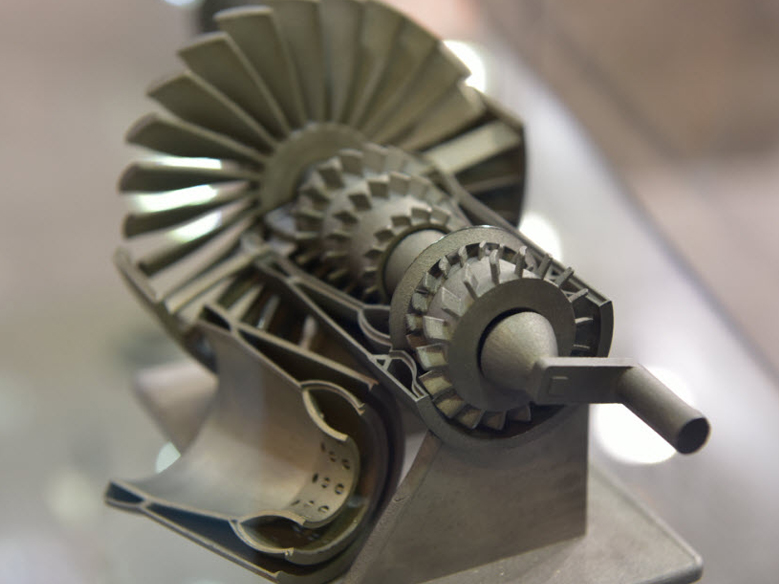

| Titanium 3D Printing Service | Seller: Industry Proto-mold Limited | Titanium 3d printing servicefor Titanium alloy parts has very high strength, precise dimensions, ... | |

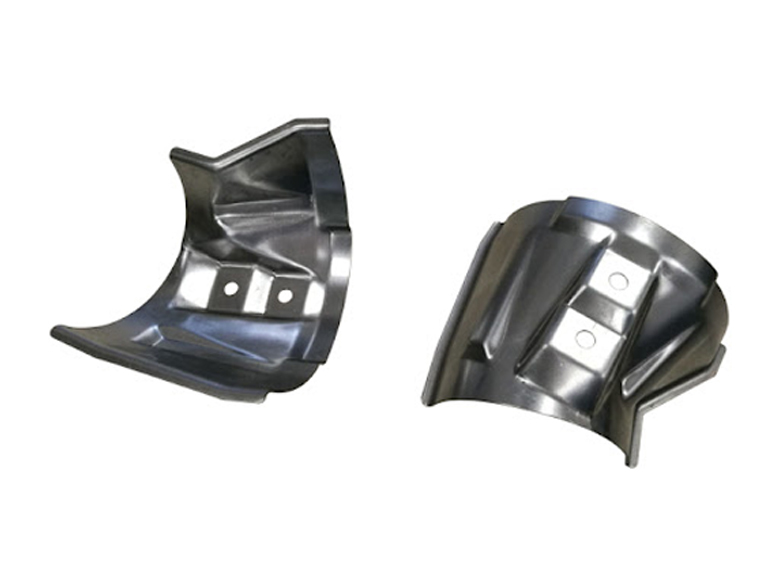

| Stamped Sheet Metal Parts | Seller: Industry Proto-mold Limited | Stamped Sheet MetalParts Proto-mold purchased advanced large laser cutting machine 3 sets, Amada... | |

| Stainless Steel Printing | Seller: Industry Proto-mold Limited | For parts with complex structure, stainless steel 3d printing servicecan realize integral printin... | |

| SLS Nylon Printing | Seller: Industry Proto-mold Limited | 3D printed nylon parts can be used for product verification or directly used as functional produc... |