Intelligent RYYT 453 Series Metal Printing Machine

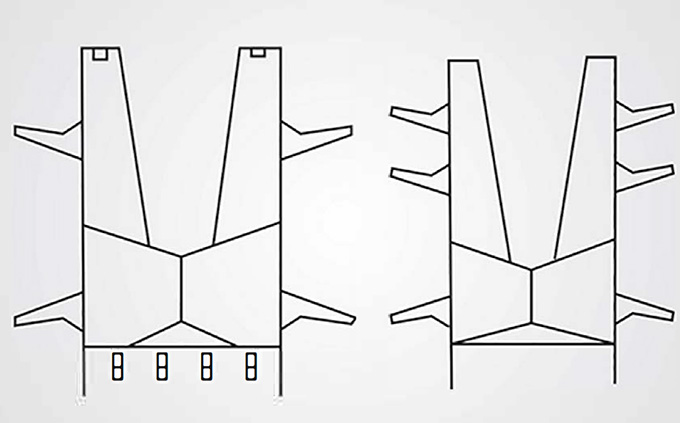

China's first intelligent metal printing machine comes from RYYT 453 series. Especially the upgraded 453 series achieve full automation, the series of metal printing press is intelligence, digital, and information, provide users with high efficiency, high performance, low cost of automatic metal printing production line. RYYT 453 series include 1-colour, 2 colour printing machine, 3 colour offset printing machine, 4 colour offset printing machine, multicolor offset printing machine and as one of the metal offset printing presses manufacturers we sell 1-color, 2 color printing machine, 3-colour, 4-colour, multi-color machines at a suitable price.

RYYT 453 Series Color Printing Press Specifications

|

CONFIGURATIONS |

RYYT2453W/2-COLOR |

RYYT4453/4-COLOR |

RYYT6453/6-COLOR |

|

Maximum sheet size |

1145×950mm |

1145×950mm |

1145×950mm |

|

Minimum sheet size standard |

712×510mm |

712×510mm |

712×510mm |

|

Sheet thickness standard |

|||

|

Maximum printing area |

1135×945mm |

1135×945mm |

1135×945mm |

|

Size of printing plate |

1160×1040×0.3mm |

1160×1040×0.3mm |

1160×1040×0.3mm |

|

Size of pre-bar blanket |

1175×1135×1.9mm |

1175×1135×1.9mm |

1175×1135×1.9mm |

|

Gripper margin |

3-5mm |

3-5mm |

3-5mm |

|

Maximum mechanical speed |

5000 sheets/hrMaximum printing speed depending upon printing shop conditions and ingoing material quality |

||

|

Height of infeed table |

916mm |

916mm |

916mm |

|

Maximum weight of feeder pile |

|||

|

Power of main motor |

17(kw/unit)x2 |

17(kw/unit)x4 |

17(kw/unit)x6 |

|

Capacity of air pump |

80+100(m³/hr) |

80+100(m³/hr) |

80+100(m³/hr) |

|

Dimension of machine(LxWxH) Length without inspection table |

10750x3700x2460mm |

19050x3700x2460mm |

26914x3700x2460mm |

|

Total connected load of machine without dryers |

56kw |

104kw |

148kw |

|

Running pressing of air cylinder |

|||

|

Compressed air |

≥140m³/h |

||

|

CONFIGURATIONS |

New generation RYYT 4453/4-COLOR |

|

Maximum mechanical speed |

6500 sheets/hr Depending on production condition |

|

K Value |

yellow (Y) ≥ 30% |

|

magenta (M) ≥ 34% |

|

|

cyan (C) ≥ 38% |

|

|

black (BK) ≥ 45% |

RYYT 453 Series Multi Color Printing Machine Main Technical Performance

Centralized control system

Central remote console, centralized control, simple and efficient metal decorating printing operation.

Automatic sheet size change

Input the sheet size in the centralized control system, press the “Confirm” button to finish the multi-printing adjustment of the pusher and side lay. Also, can a fine adjustment of the side lay in running mode, reduce manpower and higher efficiency.

Gripper front lay remote control device

The centralized control system can accurately and fast finish the fine adjustment of the front lay in running mode, it also can improve the efficiency.

INKPRO Ink fountain remote control system

Directly presetting the CIP3 date into the ink console, automatically preset the ink quantity. Then complete the ink set, through the 36 ink color sections to remotely adjust the quantity of ink in each area. The memory storage function of multiple order data presetting and read the setting data is necessary automatically. In addition, it can complete the closure of the whole ink key, also has the function with a one-button sheet closing system. Saving the time of ink mixing, with higher efficiency, reduce the chromatic aberration of different batches

Auto ink wash-up device

Finish the multi-printing press units or single-printing press unit ink wash up by one button, saving the cost of cleaning agent, reduce workforce, saving the washing time by about 35 minutes with high efficiency and green environmental protection

Alcohol dampening system

The automatic offset printing machine is composed of an alcohol box with temperature control function, water rollers, and a heat preservation sink with liquid level detection function, ensuring uniform, stable and reliable water on the layout

Electric feed

Through the button and electric motor control, the feeder can be adjusted to move left and right, forward and backward to achieve the optimal feeding position, which saves manpower and is easy to operate.

RYYT 453 Series Multi Color Metal Printing Machine

After decades of development, Ruiyuan's RYYT 453 series metal printing machine is now intelligent and convenient, greatly reducing costs and creating maximum value for customers, unanimously received the praise of customers.

Innovative Solutions of the Upgraded 453 Series

Digital sheet-change system by one button

Input the sheet size and thickness into the centralized control system, directly set up by one button: finish from the feeder - in feed - main motor - UV curing - stacker's all the gauge distance and printing cylinders press adjustment within 3 minutes, saving 37 minutes by the sheet-change system, with higher efficiency.

INKPRO Ink fountain remote control system

Directly presetting the CIP3 date into the ink console, automatically preset the ink quantity. Then complete the ink set, through the 36 ink color sections to remotely adjust the quantity of ink in each area. The memory storage function of multiple order data presetting and read the setting data is necessary automatically. In addition, it can complete the closure of the whole ink key, also has the function with a one-button sheet closing system. Saving the time of ink mixing, with higher efficiency, reduces the chromatic aberration of different batches.

Auto ink mixing device

Mixing ink device controlled by the centralized control system to mix ink automatically. Improve ink fluidity, reduce workforce, ensure ink uniform, ink more stable in normal production.

Centralized control of dampening water system

Real-time detection and automatic adjustment of the alcohol concentration of dampening, temperature, and conductivity data to keep the dampening water system stable, and helpful for high-quality printing.

Temperature control of the ink delivery system

Achieved ink constant temperature, keep the ink tack & viscosity stable, improve the quality of printing through heating or refrigeration control system, it also has the memory storage function and read when necessary.

Automatic blanket scrubbing device

Multi-printing units blanket can be cleaned at the same time by one-button control, which can reduce workforce and saving about 19 minutes with normal wash time, get the higher efficiency and protect the environment.

Test sheet management system

Save workforce and improve efficiency by test sheet management system.

Online monitoring

Online video monitoring, monitoring the differences with self-learning function, and reject the unqualified products automatically, ensure the unqualified products do not flow into the next process.

Automatic VAC Stack

To achieve non-stop production, one box is used for collecting unqualified products, the other two boxes receive the sheet change-over freely. After meeting the set collection quantities, it can land and output the sheet automatically, when receiving the pallet and rising automatically to prepare for receiving the next sheet, without any operator set up. It's very intelligent and convenient.

Automatic feeder of pallets

The device completes collection and separation of the pallet automatically, feeder moves the pallet to the stacker position automatically, without any operator set up, It's very intelligent and convenient.

For more informationabout 4 color offset printing machine priceand 5 colour printing machine, please feel free to contact us!

RUIYUAN, as one of the mostexcellent offset printing machine manufacturers, offers a wide range of china offset printing machinefor you to choose from.

Send product request

Other supplier products

| Metal Heat Transfer Thermal Oxidation Device(TNV) | Direct fired thermal oxidizer(TNV) is used to purify industrial waste gases containing high concentrations of organic pollutants, The system is cha... | |

| UV Drying Machine | The introduction of the LED UV multi-color system has revolutionized UV curing in the metal printing industry. One LED UV lamp is installed between... | |

| Metal Heat Transfer Thermal Oxidation Device(TNV) | Metal heat transfer thermal oxidation device(TNV) is used to purify industrial waste gases containing high concentrations of organic pollutants, Th... | |

| Wickets for Ovens | We can also provide various sizes and specifications of wickets with chrome plating, nickel plating, chrome plating, and zinc plating as surface tr... | |

| UV Coating Machine | As one of the leading spot uv coating machine manufacturersin China, RUIYUAN continues technological innovation of spot uv coating machine to enhan... |

Same products

| Vacuum Casting Plastic | Seller: Industry Proto-mold Limited | Vacuum casting process: free mold opening, low production cost, forming speed, high processing ac... | |

| Titanium 3D Printing Service | Seller: Industry Proto-mold Limited | Titanium 3d printing servicefor Titanium alloy parts has very high strength, precise dimensions, ... | |

| Stamped Sheet Metal Parts | Seller: Industry Proto-mold Limited | Stamped Sheet MetalParts Proto-mold purchased advanced large laser cutting machine 3 sets, Amada... | |

| Stainless Steel Printing | Seller: Industry Proto-mold Limited | For parts with complex structure, stainless steel 3d printing servicecan realize integral printin... | |

| SLS Nylon Printing | Seller: Industry Proto-mold Limited | 3D printed nylon parts can be used for product verification or directly used as functional produc... |