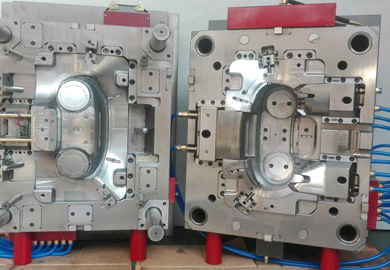

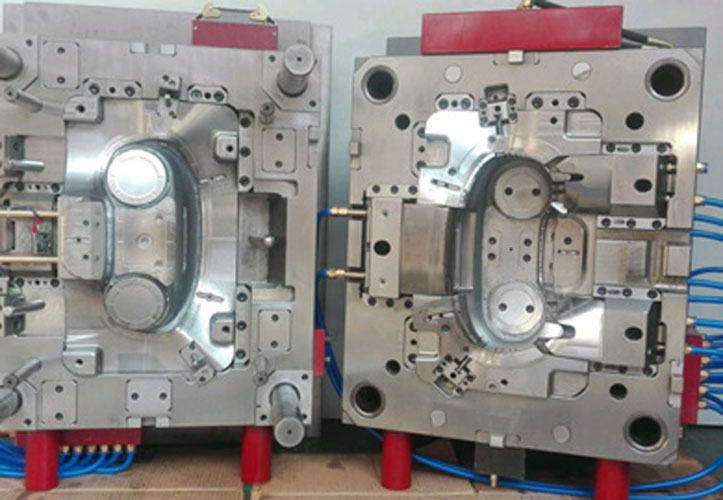

2K Mould

2k injection molding is a manufacturing process that refers to molding two materials or colors into one plastic part.

This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of the 2K mouldingprocess is generally according to cost and customization considerations.

Features of 2K Mold

Physical appearance

The physical appearance of 2K injection molding about aesthetic value or beauty is high as many colors can be blended in the molding stages.

Cost-efficiency

Because all 2K moldingmanufacturing procedures are finished in the injection stage, it can save plastic injection molding cost and lower the labor and material fees.

Customization

We can provide custom-made plastic injection molding products to meet your demanding need. It is possible to finish the products with 2K plastic injection mouldingwith softer edges.

The Specification of 2K Mould

|

Part material |

PC + ABS |

|

Cavity |

1L + 1R |

|

Mold accuracy |

+ / - 0.01 |

|

Mold steel |

|

|

Moldbase steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

6 lifters |

|

Exporting country |

Germany |

|

Delivery time |

4 weeks |

|

Mold quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

How does 2K MouldWork?

Since there are a lot of benefits of 2K injection molding, can I learn more about the working principle of 2K mould?

2K injection mouldingoperates in one machine which is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The 2K plastic injection moulding is then rotated automatically and another type of plastic is injected from a second nozzle into the mold. When using the 2k injection moldingtechnology process, material selection is very important to the injection.

GM-TECH is an experienced plastic injection molding factory, we provide plastic parts injection molding, injection molded partsand etc. Contact us to know more about plastic mold technology.

Send product request

Other supplier products

| Die Casting Mould | We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sale... | |

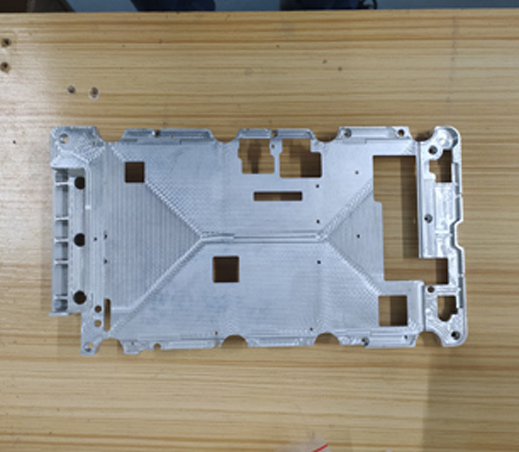

| Prototype Part | GM-TECH, a plastic injection manufacturer, has been manufacturing tools for injection molding of plastics for various industries for more than 10 y... | |

| Automotive Part | GM-TECH, injection molding supplier,has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. W... | |

| Vacuum Moulding | GM-TECH, a plastic injection company, has been manufacturing tools for injection molding of plastics for various industries for more than 10 years.... | |

| 2K Mould | GM-TECH, injection moulding manufacturers,has been manufacturing tools for injection molding of plastics for various industries for more than 10 ye... |

Same products

| How the financial industry chooses a time synchronization solution | Seller: California Triangle | In the financial industry, time synchronization is an important foundation for ensuring trading, ... | |

| Share the transformation plan of time server | Seller: California Triangle | In the era of rapid technological development, accurate time synchronization is crucial for all w... | |

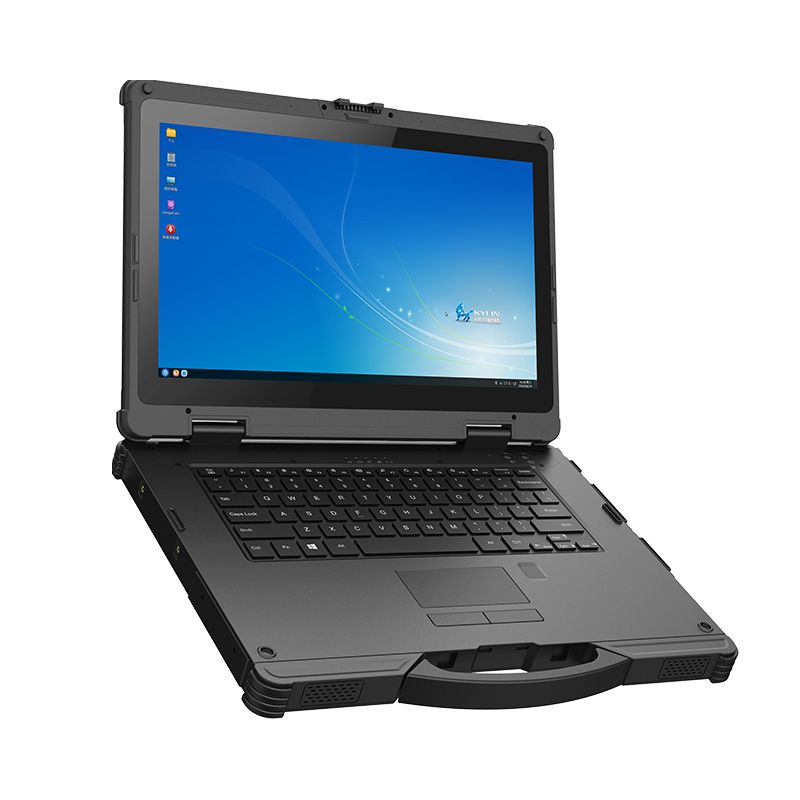

| 14 inch IP65 i5-1135G7/i7-1165G7 1920*1200 Windows Home rugged laptop | Seller: Shenzhen Sata Computer Equipment Co., Ltd | • Support for Win 10 Home system. • Intel® Core™ i5-1135G7/i7-1165G7, greatl... | |

| Super light and small industrial mini PC support DP display port for advertising | Seller: Shenzhen Sata Computer Equipment Co., Ltd | CPU Intel® Pentium N3700 (Quad Core, Quad thread, Base 1.6GHz, turbo 2.24GHz 2MB... | |

| 7 inch Full IP67 waterproof 1000nits sunlight readable capacitive touch screen monitor | Seller: Shenzhen Sata Computer Equipment Co., Ltd | Panel size 7" Resolution 1024*600 Aspect ratio 16:9 ... |