Plastic Injection Molding Machine

Focus on quality and professional industries solutionNINGBO LEADWAY MACHINERY TECHNOLOGY CO.,LTD.Dear sir or madam,Website: thanks for your attention and trust our LEADWAY Company, and giving us the opportunity to cooperate with your esteemed company. In order to make sure that you can buy an ideal brand IMM, please read the whole file carefully.The LEADWAY FÜHRUNG Series IMM accumulated our team's years of knowledge & experience of IMM, this series IMM focus on providing clients the high speed, high efficiency, reliable and professional solutions. Till now, Chinese brands IMM in the world-wide always means low price, and unreliable quality, and only can work some low doorsill products, in the high-tech required and professional industries, clients have to pay a sky-high price to buy the Euramerican & Japanese brands IMM, and it made the investment risks to be high. LEADWAY FÜHRUNG Series IMM adopted the latest European technology, world top quality brands electrical & hydraulic parts, the key mechanical parts, like: platen, cylinder, spline, tie-bars, toggle pins, etc., our suppliers are same as the KraussMaffei, ENGEL, DEMAG, SUMITOMO, WOOJIN in China. On technology, our technicians were the main responsible persons for some world famous brands IMM OEM projects. This made our FÜHRUNG Series IMM keeps pace with the world advanced technology and will be able to process the high level & professional projects.Thanks to all of our reliable & friendly suppliers' best support, and our outstanding Admin dept. LEADWAY controlled its cost in a competitive range, thus made us can provide you a pretty competitive price on your hard projects, and will reduce your investment risks immediately, for some normal products, LEADWAY FÜHRUNG Series also will be your ideal choice, for its affordable price, high efficiency & reliable quality, which will help you to keep a normal production without worries, increase your production capacity & products quality, and increase your marketing competition.In order to thanks for your support to our company, we will reward you with our advanced machines, competitive price and all-around service; make both of us achieve a successful and fruit-full cooperation.Thanks and best regardsLEADWAY MACHINERY TECHNOLOGY CO., LTD.Kris Lou – Sales Manager1. About LEADWAY:Leading TechnologyExperienced & Efficient TeamAccurate & Reliable MachineryDevelopmental Innovation & ResearchWorld-wide 7 x 24 ServiceAffordable PriceYour Solution & Custom-made Partner(Operation side of FÜHRUNG series IMM)(Non-operation side of FÜHRUNG series IMM)The FÜHRUNG injection molding machine adopted the most optimized design; it is the best toggle IMM in China, and near performance as European IMM, especially with an acceptable price.2.Why LEADWAY?2.1. Technology team: From 2006 to 2010, LEADWAY team was an OEM team for some European machines, we accumulated lots of experience on advanced technology, this is why we know how to make quality machines, and we also know customers needs on quality, safe and efficient machines.2.2. Excellent suppliers: Machine parts is one of the most important factor for machine quality, LEADWAY not only adopts the top level parts for hydraulic and electric unit, but also the mechanical unit we also cooperate with the same suppliers of KRAUSSMAFFEI, ENGEL, HUSKY, DEMAG, etc. The excellent suppliers and quality parts are our first step to ensure our excellent quality.2.3. Most strict installation and inspection: Using quality parts is not all for quality, the strict installation and inspection is another most important factor for machine quality, each set of machine from LEADWAY Company was installed and inspected under the strictest condition. 2.3. Safety machine: During production, safety is the most important. LEADWAY machine has the most reliable hardware, this is the first step of safety; Secondly, we cooperate with TÜV Rheinland, it ensure our machine can meet your high necessary for safety.Before start each machine in our factory, LEADWAY needs the hydraulic oil must through the filter, ensure hydraulic oil to pump is clean enough, it's quite important for machine working life, and ensure each machine to customer is qualified Remarks: We are able to supply customers the CE certificated machines, but pls note it in orders.2.4. We got reputation from the top quality competitors - When LEADWAY's first FÜHRUNG machine showed in Europe, lots of competitors engineers (such as: ENGEL, ARBURG, DEMAG, KRAUSMAFFEI) visited us, our quality and design got their high praised.2.5. First-class customers: Because of LEADWAY's excellent quality, lots of customers who were using European machines are turning to LEADWAY, and we are the supplier of SIEMENS in Brazil. Now, we also won lots of orders from Europe market.2.6. Stricter precision standard: (comparison of GB and LEADWAY standard of platen parallelism)Clamping Force "0"Space between tie-barsChinese GBLEADWAY standard≧200 ~ 250mm≦0.25mm0.10 ~ 0.15mm>250 ~ 400mm≦0.30mm0.10 ~ 0.20mm>400 ~ 630mm≦0.40mm0.15 ~ 0.30mm>630 ~ 1000mm≦0.50mm0.15 ~ 0.35mm>1000 ~ 1600mm≦0.60mm0.20 ~ 0.40mm>1600 ~ 2500mm≦0.80mm0.35 ~ 0.55mmMax. Clamping ForceSpace between tie-barsChinese GBLEADWAY standard≧200 ~ 250mm≦0.12mm0.08mm>250 ~ 400mm≦0.15mm0.10mm>400 ~ 630mm≦0.20mm0.15mm>630 ~ 1000mm≦0.25mm0.20mm>1000 ~ 1600mm≦0.30mm0.20mm>1600 ~ 2500mm≦0.40mm0.30mm3.LEADWAY FÜHRUNG Series Machine Main Advantages:Energy Saving:Precision and energy saving servo system with optimized designed hydraulic circuit, the energy saving capacity is near with full-electric machine.High speed:Fast response hydraulic system, sensitive controller system, and the best optimized mechanical sys., highly improved machine's cycleModularity:You can always come back for seconds, thanks to FÜHRUNG modular design, upgrades and retrofits are a piece of cake.Reliability:All of hydraulic and electric parts adopt world top brands, the whole mechanical system's rigidity is much higher than Chinese normal IMM, the key mechanical parts' supplier same as world first-class IMM brands.Stability:More than 20 years experience in this field, and several years OEM experience for world famous brands IMM, FÜHRUNG series can serve you perfect performance and stability.Clean:Maintenance free lubrication material used on adjustment sys., linear guide rail for injection system, grease lubrication for movable platen, ensure a clean production environment for you.Cost-performance:FÜHRUNG not only has the near performance with world high level IMM, but also its price is easy affordable.Individuality:We will custom-made your FÜHRUNG according to your menu and necessary, and our wide range options nearly covered all of your necessary.User-friendly:Easy for operation, convenient for maintenance, FÜHRUNG makes everything easy.4. LEADWAY FÜHRUNG Series Machine Advantages on Each Unit:4.1 Clamping Unit:With the global necessary for low-carbon and environmental protection, and the fast development of plastic industry, multi-cavity, light-weighting and fast cycle already become the demands for injection molding factories, AND, FÜHRUNG will be your right choice.4.1.1. FÜHRUNG machine main advantages of clamping unit:● Larger space between tie-bars, suitable for larger molds and multi-cavity necessary.● Longer and wider guide length, higher repeatability precision, improve product quality and mold working-life.● EUROMAP T-SLOT platen, easy for moulds installation.● Better designed mechanical structure and toggle system, faster cycle time, and improve production efficiency.● European type ejector structure, larger space, convenient for maintenance.● Prepared enough space for upgrade and retrofits.● Built-in and adjustment free mechanical safety bar, more safe and convenient.● Upgraded parts, Graphite-copper bushes and slider used on tie-bar, ejector and movable platen, ensure fast and precise mold close and open.● Much higher rigidity mechanical system than normal Chinese IMM, not only improve machine's using-life, but also can protect mold.4.1.2. FÜHRUNG clamping unit advantages to compare with Chinese brands IMM:A.Rigidity and strength comparison: (same model machine : 160T machine)From this comparison, we are easy to know that LEADWAY FÜHRUNG Series platen is much stronger than other Chinese brands IMM, the working life will be much longer.B.Repeatability precision comparison: (same model machine : 160T machine)From above picture, FÜHRUNG platen with larger size, more mould size available, and guide is wider, clamping unit keeps perfect balance, ensure high repeatability. From above picture, FÜHRUNG guide length is much longer, even moulds is very heavy, when machine move in high speed, platen still keep one-line movement, ensure the highest repeatability. C. Parts on clamping unit comparison:From above table, we are clear to know FÜHRUNG machine parts is much better than normal machine.4.2 Injection Unit:FÜHRUNG series adopt high-tech modular design, to meet various applications can adjust speed and pressure independently to mold high demanding components, for example: electric components, electric connector, thin-wall container, caps, light guide plate, optical camera lens etc.4.2.1. FÜHRUNG machine main advantages of injection unit:● Single injection cylinder, can avoid the double cylinder's pressure difference, injection more stable and precise.● Dual linear guide rail, low friction, faster speed, more precise and stable.● Dual carriage cylinder, avoid injection unit moving left and right, perfect for fast and precise injection. ● Full supported injection unit, avoid injection unit moving up and down, ● Injection proportional back-pressure control, convenient for operation, and data more stable.● All of screw L:D = 20:1, prepared the installation place for different size screws, more convenient.● To compare with normal IMM, injection speed improved higher than 30%, mold cavity easy to full filled , product internal stress will be lower and quality will be more stable.● The key parts, like injection cylinder, spline etc, our suppliers are same as world high level IMM manufacturers, reliable quality.4.2.2. FÜHRUNG injection unit advantages to compare with Chinese brands IMM:Full supported injection unit base, ensure injection unit no any up and down under high pressure injection, injection will be much more precise. Double linear guide rails, higher precise and lower friction, much lower resistance during injection and plasticization, and the injection will be more stable. Highly module design, easy for future function update and service, especially the good choice for precise and speed injection.Separated and two sides fixed injection base, long distance and empty between two sides, and guide by two bars, friction is very high, after long time working, the bars will deformation, and the bushes easy to wear, under high pressure injection, the injection unit will up and down, not suitable for precise injection,4.2.3. Normal injection unit analyzation:The normal structure injection unit movement is driven by double injection pistons, but the hydraulic oil volume in the two pistons always different, it made the force power of the two pistons are different, and will cause injection unit will shake left and right.The normal structure injection unit, when machine act the injection and plasticizing movement, the hydraulic motor will move back and forward for each cycle, and there are double injection cylinders, it means lots of friction and needs more power for this movement, and speed can not to be very fast under same energy consumption.4.2.3. Why FÜHRUNG machine injection is precise?The FÜHRUNG injection unit drives by hydraulic motor directly, few transmission mechanisms, and no hydraulic oil differences, the injection unit only move in one-line;When FÜHRUNG machine act plasticizing and injection movement, only the injection piston move inside, the injection unit no movement like normal structure, it means much less friction, and less power needed.FÜHRUNG machine injection unit adopts GERMANY TRELLEBORG rotary shaft seal, long working life and will avoid leaking.Full supported injection unit base, high speed double linear guide rails, no matter under what kinds of working condition, it keeps the best stability and repeatability.Double balance carriage cylinder, single injection cylinder, tripartite guaranty for precise injection.4.3 Hydraulic Unit:Thanks to FÜHRUNG modular designed hydraulic system, no matter energy saving technology, or simultaneous / parallel movement for high speed high efficiency production, we are easy to solve for you.4.3.1. FÜHRUNG machine main advantages of hydraulic unit:● Energy saving: standard with precision and energy saving servo power system, the output drive system is sensitively altered, according to the actual need of the plastic parts being produced, avoid energy waste. Depending on the plastic parts being produced and the material being processed, energy-saving ability can reach to 20%~80%. ● Precision: Precise servo motor with precise internal gear pump, via a sensitive pressure sensor to feedback and become close-loop control, injection repeatability precision can reach to 3‰, highly improved product quality.● High speed: High response hydraulic circuit, high performance servo system, equipped with Austria KEBA controller, it requires only 0.05sec to reach the maximum power output, cycle time is substantially shortened, the efficiency is improved significantly.● Save water: Without overflow heating for servo system, equipped with Japanese high efficiency cooler, much less cooling water required.● Environmental protection: Machine working quietly, low energy consumption; European famous brand hydraulic pipe, Germany DIN standard hydraulic pipe fitting with seal, G screw thread style plug, avoid oil pollution.● Stability: Cooperate with European famous brands hydraulic suppliers, precise control force, speed and direction of hydraulic system, ensure machine's precision, durability and stability.● Convenient: Visible and dischargeable oil tank, easy for hydraulic circuit maintenance, self-seal suction filter, reasonable placed hydraulic pipe fittings, maintenance will be easy and convenient.● Future-proofing: Modular designed hydraulic system, no matter function upgrade, or retrofit hydraulic system, our prepared installation position and space will make it so easy.4.3.2. FÜHRUNG hydraulic unit advantages:● FÜHRUNG machine adopts the most module design, it will be very easy for function upgrade, and even you want to come back for second, we prepared enough space and place for further functions.● Each part on FÜHRUNG machine selected carefully and strictly, we tested them under max working conditions, ensure machine arrived at you will be wonderful.4.3.3. Parts on hydraulic unit comparison:ItemNormal Chinese IMMFÜHRUNG machineHydraulic ValveNormal brandsComplete REXROTHValve blockBad material, and painting surface.Quality Nickel Plated.Valve block plugNormal plug with thread seal tape, and fixed by glue, maintenance is very difficult.Quality G screw thread with rubber seal, can avoid leaking. And will be easy for maintenance.Hydraulic pipeAnd fittingsLow level and cheap one, it even be danger during long time working.World-class famous brands, best quality, safe and reliable.Other PartsLow level and low price oneEach of them from the world-class and most famous brands.4.4 Electric Unit:All electric parts are from the world first-class suppliers, strong and weak current were separate distributed, main electric box, junction box adopt waterproof design, max ensured electric safety. For more details, please refer to the MAIN PARTS LIST.4.4.1. KEBA Controller:● Stable and reliable hardware: Adopt world first-class hardware and production testing technology, ensure its stable and reliable quality, IO short circuit protection function, more safety for using. All of product CE certificate, stable hardware performance reduced your maintenance & service cost.● Precise measurement and control: High precision analog input (14 bit), output (12 bit), excellent interference immunity, ensure the precision and stability of measurement and control. Analog output support voltage and current output way, and able to direct drive PQ valve and other external equipment, avoid the amplify converter's tolerance, and can save cost.● Fast response: Strong 400MHz, 32 bit CPU, 128MB SDRAM, high speed task cycle time 2ms. High performance CPU with logic task distribution system, ensure high efficient and high precise movement control, and smooth menu changing.2.4.2. More reasonable design:Till now, the servo system is one of the most energy saving power system, but there are big differences from different Injection moulding machine manufacturers, for example, LEADWAY servo driver fixed on a quality zinc-plated plate, which can discharge electromagnetism well, and will be great useful for anti-interference, and keeps machine stability. 4.5 Others:FÜHRUNG Machine base designOther brands IMM machine base design● From the above comparison, we are clear to know that FÜHRUNG special designed machine base, clamping unit moves on the base girder, much more stronger design and adopts quality structure steel, machine base will not deform after long time working.● The normal machines, machine base looks very bigger and wider, but the real weight is low, and material quite thin, this design will cause machine base deformation easily, and broke moulds and will affect production.5. LEADWAY FÜHRUNG Series Machine Main Parts List:DescriptionBrandBrand OriginElectric UnitControllerKEBA (10'' screen)AustriaServo driverLEADWAYChinaServo motorPhaseItalian ventureThree-pole automatic switchT.E.France VentureSingle-pole, Double-pole switchMollerGermanyPhotoelectric / Proximity switchSICKGermanyTransducerNovotechGermanySolid state contactorCrydomAmericaThermal Relay & AC ContactorMollerGermanyLimited switchSchmersalGermanyHydraulic UnitInternal gear pump (Servo pump)Eckeler / VoithGermanyHydraulic ValveRexrothGermanyHydraulic motor (Injection)Intra-ItalyItalian ventureHydraulic motor (Adjustment)White, EatonUSA Joint VenturePressure sensorHYDAC, KellerGermany, SwissOil SealTrelleborg, HALITEGermany, U.KPressure gaugeDMASSGermanyCoolerTAISEIJapan VentureMechanical UnitDescriptionChinese StandardDINT-slot Platen &Toggle CastingQT500-7GGG-50Tie Bar42CrMo42CrMo4VToggle Pin42CrMo42CrMo4VScrew, Barrel, Front barrel & Nozzle38CrMoAl34CrAlMo5(1.8507)Screw Tip, Lock Ring & Thrust RingSKD61(JIS)DIN1.2344Tie bar bush, Platen slide, Ejector bushCuZn25Al5Mn4Fe3GZ-Cu Al 10 Ni W.Nr.2.0975.03Linear guide railHIWIN (Brand)Taiwan (Origin)● LEADWAY reserve the right to make changes as a result of further technical advantages.6. LEADWAY FÜHRUNG Series Machine Standard Function List:The EquipmentMachine ModelINJECTION UNITStandard B screw & barrel●●●Single cylinder injection unit●●●Dual linear guide rail●●●Dual balance carriage cylinder●●●Proportional back pressure●●Screw rotation speed display●●●Injection unit transducer control●●●Auto purge function●●●Cold start protection function●●●Nozzle cover●●●CE standard double barrel insulating cover●●●CLAMPING UNITT-slot mold platen●●●Self-lubricating copper movable platen slider●●●Self-lubricating copper tie-bar bushes●●●Self-lubricating ejector plate bushes●●●Mechanical & electric interlock device●●●Mold open & close and ejector transducer control●●●Quantitative automatic centralized lubrication●●●Fixed platen water regulation●●●HYDRAULIC UNITServo motor system●●●Oil temperature indication●●●External filter interface●●●Visible oil tank●●●Self-seal magnetic suction filter●●●ELECTRIC UNITKEBA 10'' screen controller (Keplast i1075)●●●Real time working condition monitor●●●Monitoring for production data●●●Fault alarm●●●Hardware input/output monitoring●●●Three color LED tower lighter with alarm●●●Emergency stop for safety door●●●SSR (solid state sensor)●●●Power socket 3P+2 (16A)●Power socket 3P+2 (32A)●●Single phase power socket (10A)●●●OTHERSCE safety full closed machine cover●●●Full covered aluminium checkered plateLeveling pads●●●Manual●●●Tool box, Easy broken parts●●●Mold clamp●●●

Other supplier products

|

|

Rubber Compression Machine |

Rubber Compression Machine,Website: Vulcanizion Machine |

|

|

Stamping Parts |

Stamping company profileSince : 2008Employees : 86Sales : 8 millions USDProducts : Stamping tooling and stamping partsIncluding: design,Website:, m... |

|

|

Automotive Rubber Parts |

Rubber parts Company profile --- WOBSince : 1993Employees : 168Sales : 19.6 millions USDProducts: Rubber Sealing ,Website:, Chassis Rubber Part, Ma... |

|

|

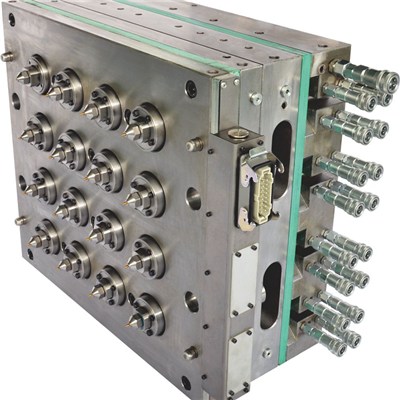

Rubber Molds |

Rubber molds and cold runnerBase on experiences of all kinds of application in different rubber production industry and rich experience which we ha... |

|

|

Vacuum Vulcanizion Machine |

Vacuum Vulcanizion Machine,Website: Vulcanizion Machine |

All supplier products

Same products

|

|

Aluminum Perforated Ceiling Panel |

Seller: FOSHAN KEENHAI METAL PRODUCTS CO., LIMITED |

Aluminum Perforated Ceiling Panel |

|

|

slewing bearing |

Seller: Henan Zengkun Machinery Equipment Co.,ltd. |

Precision Four Point Contact Ball Slewing Bearing With External Gear

SDQ-816 Precision Four Poin... |

|

|

Busbar For EV/HEV Automobile Capacitor |

Seller: Xiamen Galaxy Precision Technology Co., Ltd |

The electrical bus bar is available in rectangular, cross-sectional, round and many other shapes.... |

|

|

Flexible Bearing For Harmonic Reducer |

Seller: Henan Zengkun Machinery Equipment Co.,ltd. |

Flexible Bearing For Harmonic Reducer

Harmonic Reducer Bearing Transfer Motion And Power By Me... |

|

|

Robot Reducer Bearing For RV E And RV C Type Reducer |

Seller: Henan Zengkun Machinery Equipment Co.,ltd. |

At Present, There Are Two Kinds Of Reducers Used In The Field Of Robots, One Is RV Reducer, The O... |