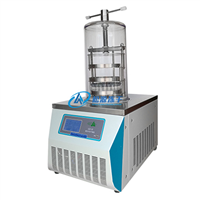

vacuum freeze dryer

The vacuum freeze dryer consists of a refrigeration system, a vacuum system, a heating system, and an electrical instrument control system. The main components are drying ovens, condensers, refrigeration units, vacuum pumps, heating/cooling devices, etc. The working principle of the vacuum freeze dryer is to freeze the items to be dried to below the triple point temperature, and then vacuum the solid water (ice) in the object to directly sublimate into water vapor, remove from the items, and make the items dry. After the material is pre-treated, it is sent to a quick-freezing chamber for freezing, then sent to a drying warehouse for sublimation and dehydration, and then packaged in a post-processing workshop. The vacuum system establishes a low pressure condition for the sublimation drying chamber, the heating system provides the sublimation latent heat to the material, and the refrigeration system provides the required coldness to the cold trap and the drying chamber. The vacuum freeze dryer adopts high-efficiency radiant heating, the material is heated evenly, the high-efficiency catching cold trap can be used, and the quick defrosting can be realized; the high-efficiency vacuum unit can be used, and the oil-water separation can be realized; the parallel centralized refrigeration system is adopted, and the multiple-channels are on-demand cooling. Working conditions are stable and energy-saving; artificial intelligence is used to control, with high control accuracy and easy operation.

The quality requirements for freeze-dried products are: constant biological activity, uniform appearance, color, full shape, firm structure, fast dissolution rate, and low residual moisture. To obtain high-quality products, we should have a more comprehensive understanding of the theory and process of freeze-drying. The freeze-drying process of the vacuum freeze dryer includes pre-freezing, sublimation and re-freezing in three stages. Reasonably and effectively shortening the cycle of lyophilization has obvious economic value in industrial production.

The application of vacuum freeze dryer is very extensive, and the frequency of use is also very high. Therefore, whether the vacuum freeze dryer can be used normally is very important to the enterprise. We all know that cars need regular maintenance after driving a certain distance. The same applies to other mechanical equipment, including vacuum freeze dryers. It is necessary to do the vacuum freeze dryer cleaning work.

Vacuum freeze dryer long-term work will bring wear and dust and other impurities covering the impact of work, let's take a look at the vacuum freeze dryer does not clean the hazards:

When the evaporator of the vacuum freeze dryer indoor unit and the condenser of the outdoor unit become dusty, it will affect the distribution of cold air and heat, which will result in the vacuum refrigeration dryer cooling or heating effect is weakened, and it takes time and time; when vacuum freeze-drying When the machine is turned on, the bacteria in the vacuum freeze dryer will be directly blown into the air in the room, causing direct damage to the human body. After the vacuum freeze-dryer was discontinued in the past summer, the vacuum freeze-dryer was neglected. Therefore, a large amount of dust, mites, pollen, scorpions, and molds adsorbed on the vacuum freeze-dryer's dust-collection network began to multiply. When the vacuum freeze-dryer is used again in the second year, these germs, viruses, molds, and dust are blown out by the dryer, often causing large-scale respiratory infections and allergic dermatitis.

For more product information, please come to the station for consultation:

Other supplier products

All supplier products

Same products