Inconel alloy Superalloy CNC Machining Services

Introduction to Inconel Alloy Superalloy CNC Machining Services

Inconel alloys are a family of high-performance, nickel-based superalloys known for their excellent strength, oxidation resistance, and ability to withstand high-temperature environments. These materials are widely used in,, and, where components must endure extreme conditions, including high pressure, corrosive environments, and thermal stress. At NewayAero, our Inconel Alloy Superalloy CNC Machining Services leverage advanced computer numerical control (CNC) technology to produce exact and complex components from these superalloys.

The CNC machining process involves using automated machine tools to precisely remove material from a workpiece to achieve the desired shape and dimensions. This process is particularly suited to Inconel alloys due to their high strength, which can make them difficult to machine using conventional methods. CNC machines are programmed with digital instructions, allowing for high precision, repeatability, and efficiency in the production of complex parts such as turbine blades, casings, and other high-performance components. By using CNC machines, we can achieve tight tolerances and intricate geometries that are essential in ensuring the reliability and performance of superalloy components.

The process begins with selecting an appropriate Inconel alloy grade for the specific application. The workpiece is then securely mounted on the CNC machine, and the machining process begins. Depending on the part's complexity, various machining operations such as turning, milling, drilling, and grinding may be performed. Special attention is given to temperature control during machining, as the heat generated by cutting can affect the material's properties. Cooling systems and cutting tools are optimized to handle the high thermal demands of Inconel alloys, ensuring a high-quality finish and minimal tool wear.

After machining, the parts undergo post-processing steps such as heat treatment, surface finishing, and inspection to meet the required mechanical and dimensional specifications. This is particularly important for components that must meet strict industry standards for performance and durability. NewayAero's CNC machining services for Inconel alloys help ensure precision, consistency, and the superior quality required for high-performance applications.

Common Grades of Inconel Alloys for CNC Machining Services

Common grades of Inconel alloys used in CNC machining services include:

Inconel Alloy Grades

- Inconel 600

- Inconel 718

- Inconel 625

- Inconel 713C

- Inconel X-750

- Inconel 718C

For example, Inconel 600 is highly resistant to oxidation and corrosion, making it suitable for applications in chemical processing and nuclear industries. Inconel 718 is a high-strength alloy commonly used in turbine engines and other aerospace applications, while Inconel 625 offers excellent fatigue and thermal-fatigue strength and is often used in marine and chemical processing environments. These alloys, along with others, are machined to tight tolerances to ensure the performance and reliability of the final components.

At NewayAero, our Inconel Alloy Superalloy CNC Machining Services deliver parts with superior precision and durability, helping industries that rely on high-performance alloys to meet their most demanding operational needs.

Send product request

Other supplier products

| Aluminum Casting Service: Aluminum Die Casting | We offer custom aluminum casting services from design to finished aluminum die castings. We aim to provide customers with excellent custom alumin... | |

| 3D Printing Prototyping Service | Affordable 3D Printing Services for Rapid Prototyping:Need a quick turnaround on your product prototype? Our 3D printing services offer affordabl... | |

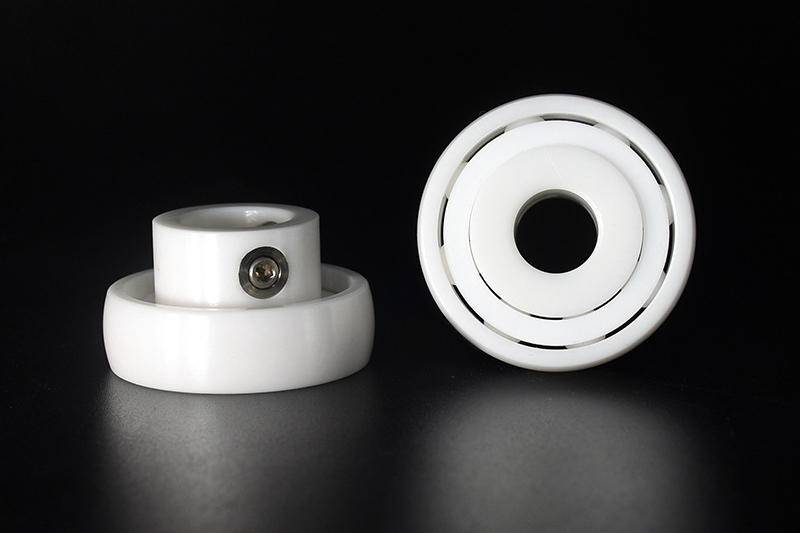

| Ceramic Injection Molding(CIM) for Custom Ceramic Parts | Excellent on-demand ceramic injection molding service for manufacturing custom CIM parts. Get your custom CIM components in exceptional quality a... | |

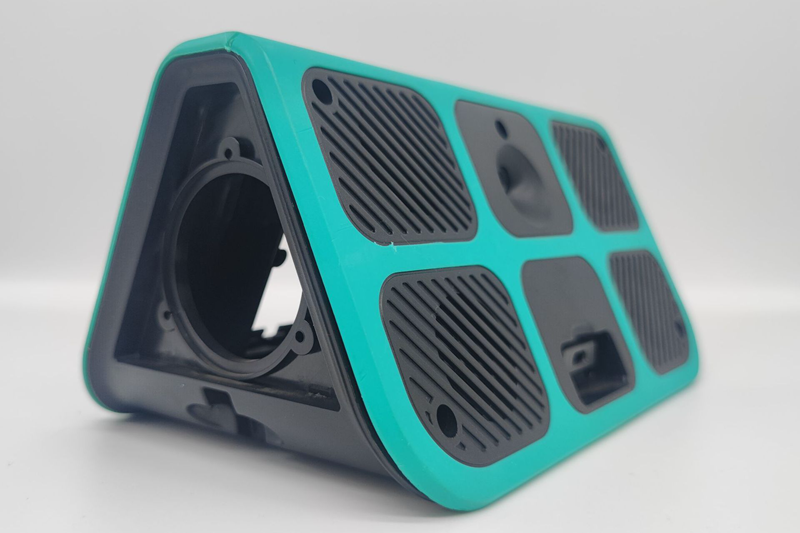

| Custom Overmolding Process | Access 30 years of experience as a custom overmolding manufacturer for your custom parts. Get exceptional customized overmolding parts with high ... | |

| Titanium Alloy Vacuum Investment Casting Service | Introduction to Titanium Alloy Vacuum Investment Casting Service Titanium alloys are known for their excellent combination of strength, lightweigh... |

Same products

| Petroleum Valve Casting CoreTech Series | Seller: Qingtian Baoli Casting Co., Ltd. | Petroleum Valve Casting CoreTech Seriesoffers a steady foundation for producing valves used in fl... | |

| Bathroom Bi-stable Sensor Faucet Solenoid Valve | Seller: Zhejiang Fuxin Electrical Technology Co., Ltd. | The Bathroom Bi-stable Sensor Faucet Solenoid Valve is designed for use in sensor-controlled syst... | |

| Wear-resistant carbide guide wheel guide roller | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable p... | |

| High precision tungsten carbide guide wheel guide roller | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable... | |

| Portable Wooden Sleeper Drilling Machine | Seller: Wuhan Linkage Track Equipment Co., Ltd |