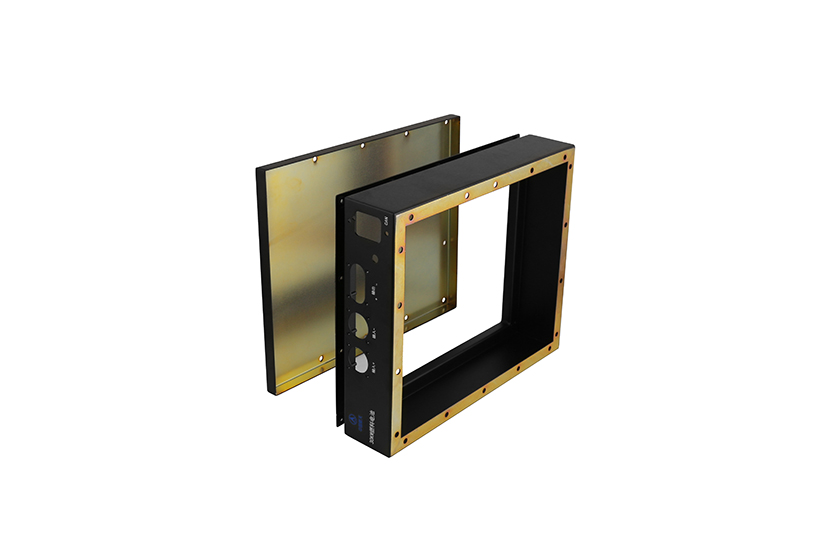

Bending Forming Box

Detail

Sheet metal box bending, also known as metal box fabrication, is often used to deform material to an angular one, which is one of the most important aspect of sheet metal forming bending. As one of the most experienced china sheet metal suppliers, HSF fabrication supplies custom sheet metal boxes, which vary from aluminum sheet metal box to iron sheet box, sheet metal junction box, etc.

The aluminum sheet is bent ( the first set of bending needs to be tested, look at the gap, and consider whether it can be assembled smoothly after surface treatment). The riveting injection ( this is not dusting, the temperature of the oven 160-degree temperature is required for the plating), silk screen printing Word white ( When silk screen printing, you need to prepare silk screen stencil in advance, the color ink required by the customer, this general color number or sample reference).

We have different sheet metal boxes for sale. Customized service can be done by customers 3d drawings and sample or your detail requirements. For more details, you may leave a message or contact us via

The Material of Sheet Metal Box Bending

We can use various materials for sheet metal box fabrication, including 316, 304 stainless steel, carbon steel, alloy steel, alloy aluminum, zinc alloy, titanium alloy, copper, iron, plastic, acrylic, POM, UHWM, and other raw materials.

Tolerance of Sheet Metal Box

Tolerance:0.1mm-0.2mm.

Surface treatment requires a sample or Pantone color number. Powder spraying: electrostatic spraying of powder coating, also known as spray coating. It uses a special electrostatic spray gun. After the paint is sent into the spray gun by means of compressed air, it is negatively charged near the corona discharge electrode of the electrostatic spray gun. Electrostatic force and dipole forces. Then, under the pressure of the conveying gas, the paint particles fly away from the spray gun and fly along the power line to the positively charged workpiece, and are arranged according to the distribution density of the surface power lines of the workpiece, so that the paint is firmly coated. On the surface of the workpiece.

Application of Metal Box Fabrication

Auto machinery, Household item, Medical equipment, Electrical, etc.

Metal box fabrication – Examples of formed metal parts we have produced include: small box, enclosure, Clamps, Mounting Brackets, etc.

This product is also a 3D drawing provided by the customer, we produce it. Precision stamping parts are thin-plate hardware, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is - parts with constant thickness during processing.

Processing Technology: Sheet metal fabrication and CNC laser cutting sheet metal, bending, welding.

Send product request

Other supplier products

| Precision Sheet Metal Cabinets | Precision Sheet Metal Cabinets Material: low carbon steel, (there are other materials we also offer such as stell, sus, iron, and so on.) Prod... | |

| COMBINED ELECTRONIC ENCLOSURES | Our electronic metal boxis made of galvanized sheet and the surface is not treated. The production process throughout wear gloves to ensure that th... | |

| LASER CARVING PLATE | What is laser carving? Radium carving refers to laser carving, is through the laser beam of light can lead to chemical and physical changes of sur... | |

| SUS Parts Laser Cutting | The alloy of copper and zinc is called brass! The content of brass elements affects its processing properties. Our brass has strong wear resistance... | |

| SECC Stamping & Forming Shell | SECC Stamping & Forming Shell Material: SECC (Electrolytic plate) 2.0mm Surface treatment: powder plating + silk-screen printing (we also... |

Same products

| ARM Cortex-A53 controller support Linux Ubuntu with 4DI to Pulse countin/Data control for smart factory | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM 2*Cortex-A53 computer with 2DI+2DO support Ubuntu for energy storage | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| T507-H processor Controller 8GB eMMC 1GB DDR4 + 4RS485 support Linux for edge computing | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM Computer 8GB eMMC 1GB DDR4+16GPIO support Docker for Industrial IoT. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| 1.4GHz Computer with 4*PGIO support Ubuntu for Energy Storage ARM Computer. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... |