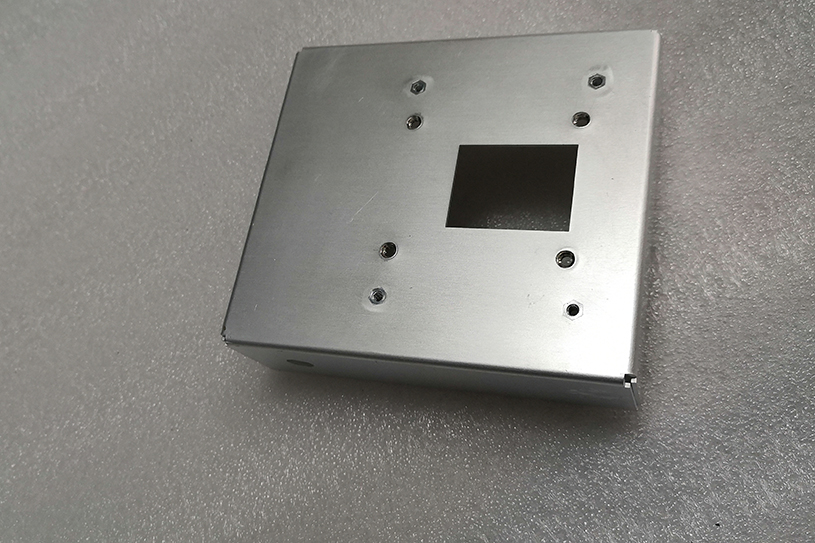

SECC Stamping & Forming Shell

Material:

SECC (Electrolytic plate) 2.0mm

Surface treatment:

powder plating + silk-screen printing (we also offer logo or words printing)

Optional effect:

flat light, sprinkle, light, orange, sand

Custom PCB electronic component box

This product is also a 3D drawing provided by the customer, we produce it. Precision stamping parts are thin-plate hardware, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is - parts with constant thickness during processing.

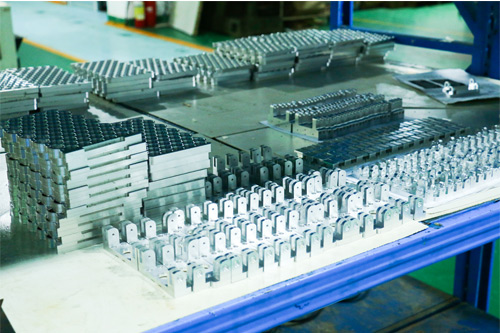

Precision stamping parts are thin-plate hardware, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is - parts with constant thickness during processing. Corresponding to the casting parts, forging parts, machined parts, etc., for example, the outer iron shell of the car is a sheet metal part, some of the stainless steel cabinets are also sheet metal parts. Shenzhen HSJ Metal Fabrication Co., Ltd. professional hardware precision stamping manufacturers.

Surface treatment requires a sample or Pantone color number. Powder plating: electrostatic spraying of powder coating, also known as spray coating. It uses a special electrostatic spray gun. After the paint is sent into the spray gun by means of compressed air, it is negatively charged near the corona discharge electrode of the electrostatic spray gun. Electrostatic force and dipole force. Then, under the pressure of the conveying gas, the paint particles fly away from the spray gun and fly along the power line to the positively charged workpiece, and are arranged according to the distribution density of the surface power lines of the workpiece, so that the paint is firmly coated. On the surface of the workpiece.

Copy paint: a special electrostatic spray gun is used, which uses the airflow from the compressed air to form a gas pressure difference with the tube connected to the paint can, so that the paint liquid is sucked up from the paint can, and the air flow of the compressed air is brought to the nozzle and blown into fine The spray is evenly sprayed on the surface of the workpiece.

The common advantages of powder plating: impact resistance, corrosion resistance

Powder plating Inspection of paint products: All surfaces should not be white, no scratches, no bubbles, no wrinkles, no pinholes, no powder, no paint.

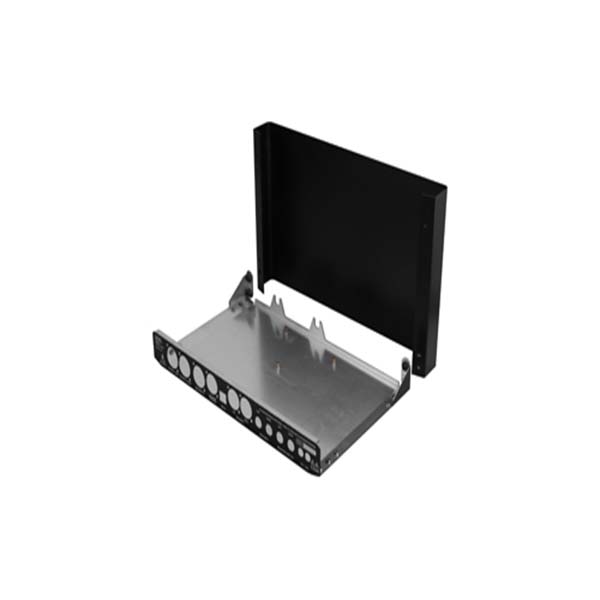

We provide galvanized steel cabinetand galvanized metal cabinet for you.

As one of the mostprofessional sheet metal fabrication companies, we provide metal fabrication service china,china cnc sheet metal fabrication, galvanized steel junction box, galvanised metal cabinet, secc sheet metal, galvanised steel junction boxand etc. Want to know more? Please contact us.

Send product request

Other supplier products

| Machined Enclosures | Material: Carbon Steel/Stainless Steel/aluminum Surface treatment: Paint, powder coat, polish, silk-screen printing, anodize, electronic plate... | |

| CNC METAL PARTS | CNC metal parts are about to turn the manual work into computer programming. Of course, you need to have experience in manual processing. General C... | |

| Laser Carving Plate | Laser Carving Plate Produce material: aluminum Process: laser carving Tolerance: +-0.1mm Thickness: Packing: packed with carton an... | |

| Products | Aircraft sheet metal fabricationis the method of building machines and structures from raw metal materials like plate metals. aluminium sheet fabri... | |

| Sheet Metal Laser Cutting | Laser cutting sheetis used successfully in a wide variety of industries. Cutting materials with high power density laser beam. The thickness of the... |

Same products

| ARM Cortex-A53 controller support Linux Ubuntu with 4DI to Pulse countin/Data control for smart factory | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM 2*Cortex-A53 computer with 2DI+2DO support Ubuntu for energy storage | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| T507-H processor Controller 8GB eMMC 1GB DDR4 + 4RS485 support Linux for edge computing | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM Computer 8GB eMMC 1GB DDR4+16GPIO support Docker for Industrial IoT. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| 1.4GHz Computer with 4*PGIO support Ubuntu for Energy Storage ARM Computer. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... |