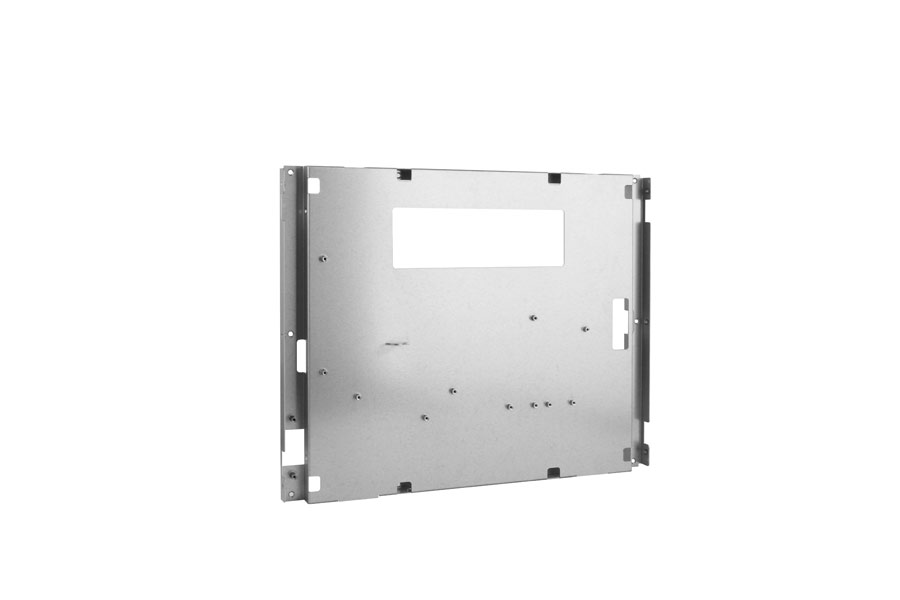

CNC Custom Aluminum Parts

Custom Aluminum CNCParts

Material:

aluminum

Process:

Cnc machine-wire drawing-reveting-anodizing-silk printing

Color:

steel color(we offer powder coating and we supply red,black,blue and other colors )

Tolerance:

+-0.1mm

The surface of this product is very smooth. There is no burr at the edge of the board.

Its application is in the electrical field.

Custom aluminium machiningadvantages are stable processing quality, high precision, high repetition accuracy.

The advantages of custom CNCaluminumare good quality, high size accuracy, better finish,not easily deformed and long service life.

(After wire drawing, there should be no scratches or bruises on the surface.)

Wire Drawing: it is a kind of abrasive belt grinding. By grinding the metal surface with sand belt, the defects on the metal surface can be removed and the decorative surface with uniform grain can be formed.

Packaging Details

As one of custom cnc aluminum parts manufacturers, we provide you withcustom machined aluminum parts.

If you want to know more details of china sheet metal process, please visit our website.

As one of sheet metal components manufacturers, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Stamping Panel Parts | Detail Introduction of stamped sheet metal panels Material: aluminum galvanized sheets(stainless steel, mild steel, steel alloy) Process: stamping... | |

| CNC Stainless Steel Parts | Stainless Steel CNCParts Material: sus Tolerance: Machining standards: limited linear dimension tolerance ±0.1mm,geometric dimension &... | |

| High Precision CNC Parts | High Precision CNC Parts Feature: small-volume CNC machining, custom-made CNC aluminum parts, each detail size meets customer requirements, toler... | |

| HIGH PRECISION CNC PARTS | High precision CNC parts made by HSJ Our product is small-volume CNC machining, custom-made CNC aluminum parts, each detail size meets customer req... | |

| Sheet Metal Cabinets | Sheet metal has the characteristics of light weight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, ... |

Same products

| ARM Cortex-A53 controller support Linux Ubuntu with 4DI to Pulse countin/Data control for smart factory | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM 2*Cortex-A53 computer with 2DI+2DO support Ubuntu for energy storage | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| T507-H processor Controller 8GB eMMC 1GB DDR4 + 4RS485 support Linux for edge computing | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| ARM Computer 8GB eMMC 1GB DDR4+16GPIO support Docker for Industrial IoT. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... | |

| 1.4GHz Computer with 4*PGIO support Ubuntu for Energy Storage ARM Computer. | Seller: Beilai Technology | The ARMxy BL340 series is an industrial ARM controller based on the Allwinner T507-H processor wi... |