Ethyl Acetate Plant and Process Technology

There are 4 main prevailing processes for , i.e. Direct Esterification Process, Acetaldehyde Condensation Process, Ethanol Dehydration Process and Acetic Acid-Ethylene Addition Process. Each process has its advantages and its applicable services. Our process is based on reactive-distillation esterification, which is mature, low costing and suitable for those with acetic acid feedstock.

Advantages of Our and Process Technology

In our reactive distillation process, organic acid catalyst is used; its advantages cover the followings:

Low ethanol consumption

Low catalyst dosage

High catalysis activity

Low equipment corrosion

Less side reactions

Higher product purity

Simple post-treatment operations

Send product request

Other supplier products

| ECH production process by glycerin method | Epichlorohydrin is the main raw material for the production of epoxy resin. It is also an important organic chemical raw material and fine chemica... | |

| Proprietary Technology and Plants China | Concentrated Recycling Technology of Formaldehyde Proprietary Technology and Plants Technical Features: In the production of paraformaldehyde an... | |

| Fixed Bed Process Hydrogen Peroxide Plant | Fixed Bed Process Hydrogen PeroxidePlant Product Description There are several methods for hydrogen peroxide production and manufacturing, among ... | |

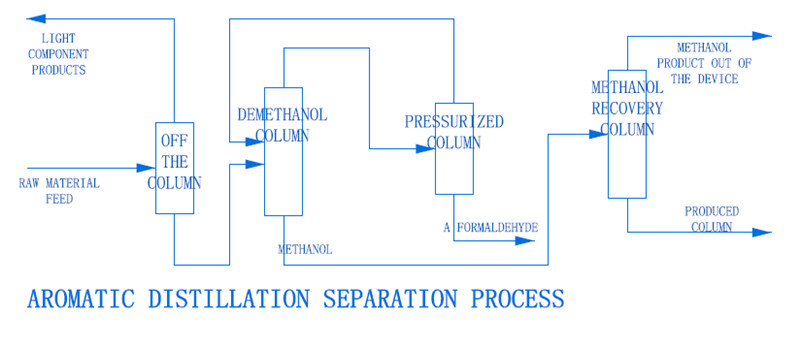

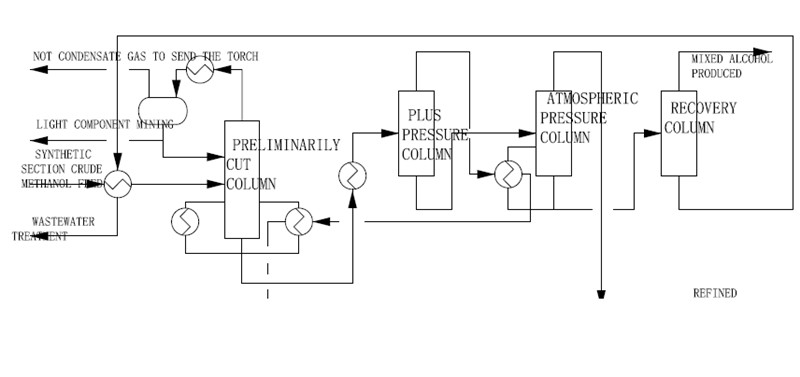

| Proprietary Technology and Plants | Crude Aromatic Separation Technology Proprietary Technology and Plants TechnologyIntrodction: Our company offers naphtha cutting, reorganization... | |

| Methylal Refining Technology | Methylal Refining Technology Proprietary Technology and Plants Technical Features: Methaldehyde has excellent physical and chemical properties, tha... |

Same products

| Trimellitic anhydride 97% | Seller: Yufeng International Group Co., Ltd | Trimellitic anhydrideis a 2-benzofuran compound having oxo groups at the 1- and 3-positions and a... | |

| Isobutyric Anhydride CAS 97-72-3 | Seller: Yufeng International Group Co., Ltd | Product Name: Isobutyric Anhydride CAS No.: 97-72-3 Purity: 99% Molecular Formula: C6H10O3 Mo... | |

| Isobutyric Acid CAS 79-31-2 | Seller: Yufeng International Group Co., Ltd | Product Name:ISOBUTYRIC ACID Synonyms: 2-Methylpropanoic acid 79-31-2 Isobutanoic acid 2-Met... | |

| 2-Amino-2-methyl-1-propanol(AMP)CAS:124-68-5 | Seller: Yufeng International Group Co., Ltd | AtYufeng, a trusted 2-Amino-2-methyl-1-propanol Factory & Supplier, we prioritize quality and... | |

| Dimethyl sulfoxide (DMSO) CAS: 67-68-5 | Seller: Yufeng International Group Co., Ltd | Yufengis one of the leading dimethyl sulfoxide suppliers and also a professional such manufacture... |