Membrane Bioreactor

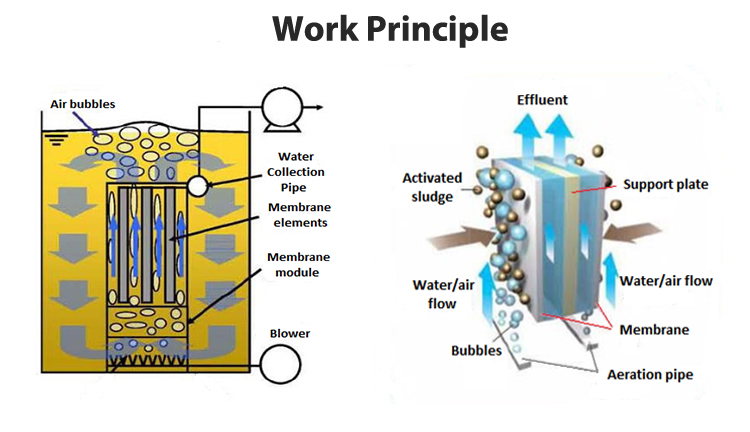

MBR (Membrane Bio-reactor) is a membrane separation technology with biological degradation. The membrane module can take the places of the secondary sedimentation tank, a large number of microorganisms are intercepted, which can increase the quantity of microflora, improve the sewage treatment capacity and efficiency, so that the effluent quality and volume load have been greatly improved, and the water can be used as reclaimed water.

The core component of the MBR is high-performance submerged membrane components. Compare with the traditional method (pressure filter), the membrane negative pressure suction type filtering method using aeration to operation a sable mbr filter membranein the system.

Technical Process and Comparison of Membrane Bioreactor

The pollutant in sewage water will firstly biodegradation in a bioreactor, at the same time, because of the function of the pressure difference, the water, and some small-molecule solute which smaller than the aperture of the membrane in the mixed liquid will pass the membrane, and then become the treated water.

Microorganisms and macro solute will be intercepted by the membrane, so it replaced the sedimentation tank by complete its water treatment and separate function.

MBR Working Principle

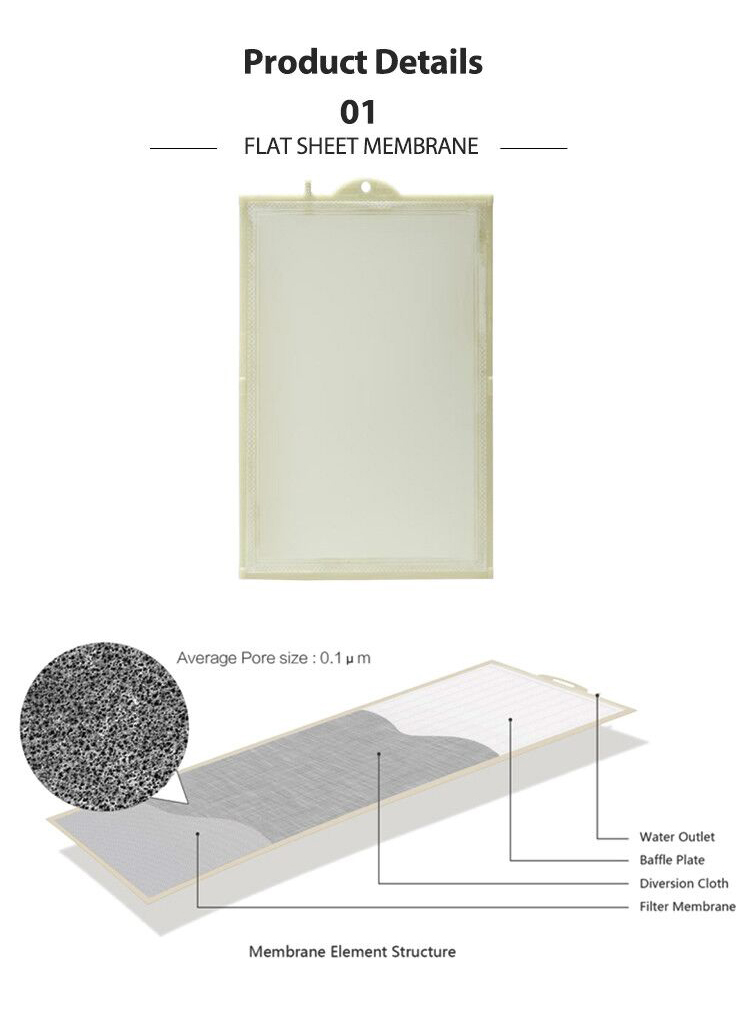

Use the PVDF as the main material, Rosun flat sheet membrane with good stability of chemicals used in wastewater treatment, fouling resistance, and mechanical strength, has different types according to its efficacy area.

Advantages of biological reactor wastewater treatment

Advanced material:

The main material of the membrane is PVDF, which has excellent chemical stability, permeate flux, permeate quality, and fouling resistance.

Better outlet water quality:

The pore size of Rosun flat sheet membrane is around 0.1micron, and with advanced membrane technology increased the effective orifice area of the membrane surface then leads to excellent permeate flux and permeate quality. The output water can be reused directly.

|

Water quality |

Traditinal technology |

MBR technology |

|

COD ( mg / L ) |

<100 |

<30 |

|

BOD ( mg / L ) |

<30 |

<8 |

|

TSS ( mg / L ) |

<30 |

<1(near zero) |

|

Turbidity ( NTU ) |

<2-5 |

<1 |

|

Bacterial ( MPN / L ) |

103-104 |

<100 |

Higher activated sludge adaption of Membrane Bioreactor:

Compared with the hollow fiber curtain membrane whose activated sludge adaption is only 4000-6000mg/L, Rosun flat sheet membrane can adapt 8000-15000mg/L activated sludge.

Longer service life:

Compared with hollow fiber curtain membrane, Rosun flat sheet have a longer service life of 3-6 years compared with 1-3years of service life of hollow fiber curtain membrane.

Less land space:

The MBR reactor tank can replace the function of a secondary sedimentation tank with an anaerobic tank, it can save 30% of land space.

Easy to operate and maintenance:

The flat sheet membrane can be just replaced a single damaged piece without change the holder when damage and replacement, replace just need 15 minutes.

MBR Membrane Bioreactor Integrated System

Basic Components:

Pre-Treatment Tank

Inner Ladder

Sludge Pump

Reaction Tank

MBR Membrane Module

Recycled Tank

Lift Pump

Air Distributor

PLC System

Disinfection Device

Control Room

MBR Membrane Bioreactor Design Module

Rosun MBR membrane module is combined with the membrane element box and the aeration box. The membrane outlet is combined by a water collection tube in the membrane element box, and each membrane element can be individually installed and unloaded for easy maintenance. For the upgrade of traditional technology, just install the membrane module in the aeration tank is ok.

Specifications of MBR Water Treatment Plant

|

Type |

RF-025 |

RF-080 |

RF-100 |

RF-150 |

|

|

Effective area(m²) |

1 |

||||

|

Size: H*W*T(mm) |

495*365*7.5 |

1030*490*7.5 |

1190*518*7.5 |

1780*490*7.5 |

|

|

Production rate ( L / pcs.day ) |

100~230 |

320~480 |

400~600 |

600~900 |

|

|

Material of components |

Membrane |

PVDF + PET |

|||

|

Outer frame |

ABS |

||||

|

Pore diameter ( μm ) |

|||||

|

Aeration rate ( L / min.pcs ) |

8 |

8 |

10 |

12 |

|

|

Weight ( kg ) |

|||||

|

Effluent turbidity ( NTU ) |

≤1 |

||||

|

Effluent SS ( mg / L ) |

≤3 |

||||

Bioreactors in Wastewater Treatment Application Cases:

Domestic Sewage Hospital Sewage

Landfill Leachate Laundry Sewage

Printing&Dyeing Sewage

Steel Circulating Water

Electroplating Sewage Tobacco Sewage

Domestic and Sewage Treatment Industry

Municipal sewage treatment and water reuse

Sewage treatment and water reuse

Hospital wastewater and water reuse

Residential area, school, scenic-tourist areas sewage treatment, etc.

Industrial Wastewater Treatment Industry

Chemical, petroleum, chemical fiber wastewater treatment

Garbage leachate treatment

Pesticide Pharmaceutical high concentration organic wastewater treatment

Slaughter, livestock manure, food processing wastewater treatment

Brewing, beer wastewater treatment

If you want to know more about mbr membrane priceand membrane bioreactor processes principles and applications, please visit our website.

As a mbr membrane manufacturer, we will do our best to meet all customers’needs.

Send product request

Other supplier products

| Livestock Poultry Pet Vet Disinfection | Established in 2002, Rosun, a professional antiseptic disinfectant products manufacturerand supplier in China, has been committed to high-end envir... | |

| Disinfectant Powder DW-1 | Rosun water disinfectant powderis an advanced oxidation technology basing on sulfate radical [SO4-], using potassium monopersulfate compound powder... | |

| Disinfectant Powder ICW-1 | Rosun Fungicide ICW-1 for sale is an advanced oxidation technology basing on sulfate radical [SO4-], using potassium monopersulfate compound powder... | |

| 50ml Skin Disinfectant | Efficient against hand intestinal pathogen, pyogenic coccus, saccharomyces, and common pathogens. Features of 50ml sanitizer spray Double steriliz... | |

| 500ml Skin Disinfectant | Features of 500ml Skin Disinfectant Double sterilization formula, broad-spectrum against intestinal pathogens, pyogenic coccus, saccharomytes, and... |

Same products

| Easy-cleaning Silicone-Modified Waterborne UV Resin | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | LUV533 is a high-performance, silicone-modified hexafunctional waterborne UV resinengineered to d... | |

| Water-based Soft-Touch Resin for Consumer Electronics | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | Water-based Soft-Touch Resinis an advanced coating material formulated to deliver a luxurious, ve... | |

| Conformal Coatings | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | The conformal coatingsprovide good adhesion to metal, PCB and other substrates after curing at ro... | |

| Metalized & Laser Transfer coating | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | Metallized and laser transfer coatingsare designed with sustainability in mind, ensuring minimal ... | |

| Hydrophilic coatings for Air Conditioner | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | A water-based coating combination applied on the surface of aluminum foil, which forms a layer wi... |