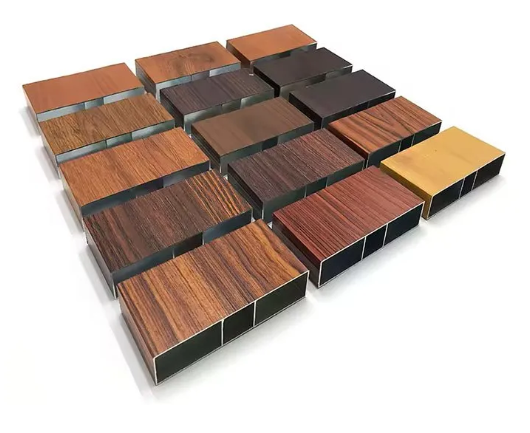

Wood Grain Powder Coatings

The wood finish powder coating process utilizes a sublimation technique that employs a combination of heat and vacuum pressure. Through this method, decorative faux wood effect patterns are transferred onto pre-cured powder-coated surfaces. As an innovative finishing solution, wood effect powder coating captures the eye-catching beauty of natural wood while integrating it with the exceptional durability of powder coating technology.

Driven by the dual considerations of natural aesthetics and enduring durability, wood grain powder coatings have emerged as a remarkable bridge connecting industrial manufacturing with the essence of nature. Though not real wood, this coating employs cutting-edge application technology to flawlessly replicate wood’s texture and character on substrates like metal and MDF. It overcomes the inherent limitations of natural wood, offering a more durable and eco-friendly surface solution.

The application of our wood grain powder coatings continues to expand, covering nearly every scenario requiring a wood-like effect. It is primarily used in home and interior decoration, furniture, appliances and electronics, construction and outdoor applications, as well as transportation and tools.

Advantages of Wood Finish Powder Coatings

1. Authentic Aesthetics with Natural Variation

Achieves remarkably realistic wood-like appearances, accurately replicating the grain patterns, color depth, and tactile feel of premium wood species

Offers diverse design possibilities while maintaining consistent quality across production batches

2. Superior Durability and Performance

Exceptional resistance to weathering, UV radiation, and color fading, outperforming conventional wood finishes

Enhanced scratch, impact, and abrasion resistance ensures long-term protection of underlying substrates

Withstands extreme temperatures and harsh environmental conditions without cracking or peeling

3. Environmental Sustainability

100% solvent-free composition with zero VOC emissions during application

High material utilization rate (typically over 95%) through recycling systems

Provides a sustainable alternative to rare wood species, supporting forest conservation

4. Low Maintenance and Longevity

Non-porous surface prevents moisture absorption, staining, and bacterial growth

Easy cleaning with simple wiping, eliminating need for special treatments or regular sealing

Maintains appearance integrity over extended periods, reducing replacement frequency

5. Versatile Application Potential

Compatible with various substrates including aluminum, steel, and MDF panels

Suitable for both interior and exterior applications across multiple industries

Enables creative designs while meeting strict safety and performance standards

6. Economic Efficiency

Reduced lifecycle costs through minimal maintenance requirements

Faster production cycles compared to traditional wood finishing processes

Eliminates need for additional protective coatings or regular refinishing

Classifications and Typical Applications

| Classification Basis | Type | Typical Applications |

| By Substrate & Process | Wood finish on Metal Substrates | Aluminum doors/windows, guardrails, metal furniture frames, appliance housings, automotive interior trim |

| Wood finish on MDF Substrates | High-end cabinets, wardrobes, interior doors, office furniture, display cases | |

| By Visual Effect | Solid Wood Imitation | Home decoration, high-end furniture, hotel interiors |

| Design/Abstract Patterns | Brand flagship stores, commercial spaces, creative furniture, art installations | |

| By Surface Tactile Sensation | Smooth Flat Finish | Door panels, table tops, appliance panels, interior decorative parts |

| Tactile Finish | Furniture frames, handles, tool grips, high-end custom products | |

| By Performance Grade | Standard Interior Grade | Indoor furniture, decorations, electrical appliances |

| Outdoor Durable Grade | Outdoor doors/windows, pergolas, railings, architectural curtain walls |

Send product request

Other supplier products

| Metal powder coatings | IntroductionMetal powder coatings are specialized finishes designed for metal surfaces. Applied as a dry powder, they are electrostatically charged... | |

| (FBE) Single Layer Epoxy Anti-Corrosion Powder Coating | Product Usage:Suitable for anti-corrosion of oil and gas transmission pipelines, municipal water supply, drainage, sewage, circulating water, chemi... | |

| Automotive Powder Coating | Introduction We are a leading Chinese powder coating factory with over 20 years of export experience, supplying high-quality coatings to automotiv... | |

| MT-A600 Series Powder Coating | Product Overview The Surpass MT-A600 Series powder coating is a high-performance coating designed specifically for computer cases, including deskt... | |

| Polyester/TGIC powder coating series | Made of polyester resin and TGIC curing agent as the main raw materials. Features: —Good adhesion, excellent mechanical properties, tough c... |

Same products

| Blue Kingfisher Ambiance Velvet Texture Paint | Soothing Interior Decorative Coating | Seller: Zhongshan Blue Kingfisher New Environmental Protection Materials Co., Ltd | Product Overview This is a paint that infuses emotion into a space. The soft, velvety matte surf... | |

| Easy-cleaning Silicone-Modified Waterborne UV Resin | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | LUV533 is a high-performance, silicone-modified hexafunctional waterborne UV resinengineered to d... | |

| Water-based Soft-Touch Resin for Consumer Electronics | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | Water-based Soft-Touch Resinis an advanced coating material formulated to deliver a luxurious, ve... | |

| Conformal Coatings | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | The conformal coatingsprovide good adhesion to metal, PCB and other substrates after curing at ro... | |

| Metalized & Laser Transfer coating | Seller: Guangzhou Human New Material Science and Technology Co., Ltd | Metallized and laser transfer coatingsare designed with sustainability in mind, ensuring minimal ... |