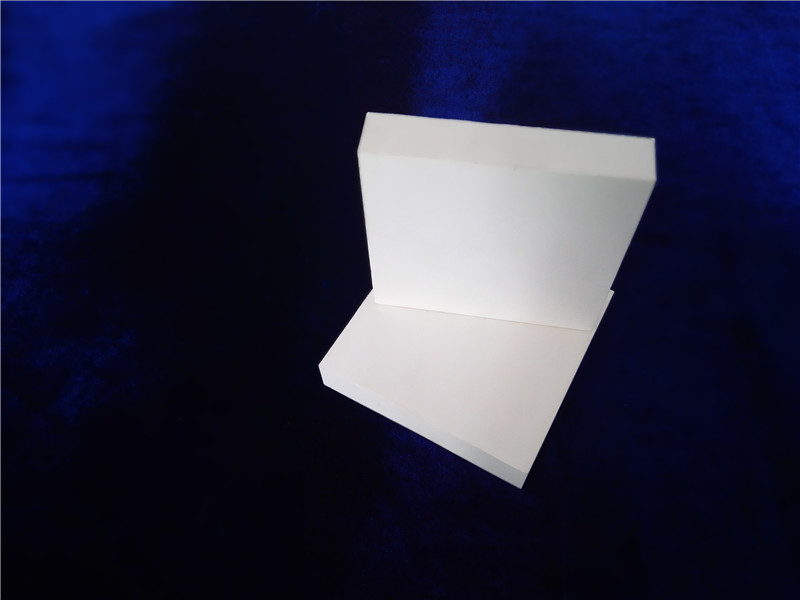

Alumina balls for dry grinding,Energy-Saving Dry Grinding Medium

We are an integrated company with the ability to manufacture abrasion-proof material, make development and sales. Focusing on the production and application of grinding medium which is dedicatedly used for cement dry grinding machine, with nearly a thousand times tests and data gathering, we finally achieved the success of complete energy-saving technology improvement with consistent effort of R&D team in three years. Several national patents have been successfully certified. Many problems of cement industry also had been solved by us.

The Performance Advantages of Energy-Saving Dry Grinding Medium Are Specially Used for Cement

1) Low Energy Consumption: The density of energy-saving dry grinding medium that special used for cement is about 3.6 g/cm3 and density of high chromium steel ball is about 7.8 g/cm3; under the same volume, using energy-saving dry grinding medium that special used for cement is twice lower than using traditional grinding medium. Also, current of main engine gets lower along with temperature rise. Meanwhile, as its weight is light, effective loading rate of grinding machine can be moderately increased, which improves efficiency of powder grinding and output per hour. Then unit power consumption gets lower.

2) Low Temperature: Energy-saving dry ceramic grinding medium that special used for cement belongs to inorganic material. During grinding process, its heating value is very low. Without any static electricity, temperature gets lower and liquidity of cement increases.

3) Low Maintenance Costs: After using energy-saving dry grinding medium that special used for cement, temperature in grinding machine is low. In addition, as the weight of grinding machine is light and the entire impact force is little, comprehensive consumption of grinder in grinding machine decreases. Meanwhile, whole damage of equipment in grinding machine, including head of machine, and end of machine decreases. Therefore, maintenance period prolongs and maintenance cost reduces.[e1]

4) Improvement of The Distribution of Cement Particle: When producing ordinary cement by energy-saving dry grinding medium that special used for cement, inner grinding machine temperature is low and electrostatic effect of grinder is low. Then grinding efficiency is high; fineness and controllability of specific surface area could be further improved. As a result, shape of cement powder particles becomes better and quantity of 3-32 micron valid particle increase largely. Then early-stage and later-stage intensity of ordinary cement improved. Because grain shape tend to be better, water demand of ordinary cement and adaptability of admixture improve, which develop comprehensive quality of cement, reputation of product, and competitive force of market.

5) Improvement of Cement Adaptability: When producing ordinary cement by energy-saving dry grinding medium that special used for cement, inner grinding machine temperature is low and temperature of outcome cement is very low. This perfectly solves cement steadiness problem that caused by short interval from cement grinding to delivery. This effect shows obviously especially when grinding cement in high temperature seasons and grinding cement in concrete.

6) Environmental Protection: All sectors of the community and environmental protection department pay more and more attention to the damage of hexavalent chromium in cement. The government made a graft to limit water soluble chromium VI in cement on May.26th, 2013. In the process of traditional ordinary cement grinding, application of high chromium steel ball and lining plate is the main source of hexavalent chromium. Thus, there are few solutions can be taken. After adopting energy-saving dry grinding medium that special used for cement and ceramic lining plate technology, content of water soluble chromium VI in cement decrease largely as it prevents direct contact between high chromium metal and cement. Its significance of low carbon environmental protection wins support and promotion from all sectors of the community and environmental protection department.

We company holds the spirit of creating value for customer, studies the need from customer, provides different solution for customers, proceeds technology creation of various solution, and improves value and service for customers. At the same time, we welcome peer elites come to our company for investigation and reasoning.

Five advantages of Alumina dry grinding ball replaces the high chromium steel ball applying to the cement grinding.

Energy Saving

1. Reduce over 40% of mill’s load capacity

2. Save over 20% energy for one ton of cement

3. Reduce over 30% energy of the mill main engine

upgrading

1, Improve the efficiency of powder grinding;

2, Improve the capacity of cement;

3, Grain composition is more rational;

4,Improve the degree of spheric grain;

5, 3-32um particle contents improve more than 2 percentage points;

6, Standard consistency water consumption reduce 1-2 percentage points;

7, Cement is good for the concrete’s adaptability.

lower the temperature and reduce the noise

1. The temperature inside the mill is reduce more than 20℃;

2. The noise of the mill is reduce about 20 decibel.

Abrasion Resistance

The ball consumption of Energy-Saving Dry Grinding Medium is 30% of the steel ball.

Environmental Protection

Energy-Saving Dry Grinding Medium is benefits for the achievement of the green manufacturing, which impeded the production of the water soluble chromium VI

Contact informaiton:

Phone:/

Web:

Send product request

Other supplier products

| Abrasive alumina lining plate and lining sheet | The products featured by high wear-resistance, impact-resistance, easy operation, etc. properties, are ideal surface wear –resistant material... | |

| Refractory brick for Ingot steel casting, Cast Steel/runner ingot brick | 1. Carbon bake furnace in the aluminium industry 2. Preheat zones and cyclones of rotary cement kilns 3. Primary reformers in fertilizer production... | |

| 92%,68%,75% alumina ball/balls,medium/Zircon alumina ball manufacturer in china | With the cutting edge technology of cold isostatic press shaping ,quality alumina powder as raw materials and sophisticated recipe,our products are... | |

| Ceramic Industrial Alumina Brick,Alumina brick for ceramic industry suppliers/manufactures | With first rate of hydraulic shaping techonology and powder out of centrifugal sprayer, the finished alumina lining bricks become regular shaped,hi... | |

| High hardness Alumina cylinder tube suppliers/manufactures in China | Properties: 1. High Temperature Up to 1700℃ 2. High Voltage Resistance 3. High Mechanical Strength and Hardness 4. Excellent Insulation Performance... |

Same products

| Tabular Alumina | Seller: ZHENGZHOU HAOYUN NEW MATERIAL TECHNOLOGY CO., LTD. | Tabular alumina for saleis a pure sintered α-alumina material. It is also known as white si... | |

| Tabular Alumina | Seller: Shengshi Jinyang Group Co.,LTD. | Tabular Alumina, with the purity, do not add any additives, and firing contraction completely fin... | |

| BETA ZEOLITE | Seller: Pingxiang Naike Chemical Equipment Packing Co.,Ltd. | Beta Zeolite Beta Zeoliteis the only one structured with three-dimensional 12-membered ring ch... | |

| BERL RING | Seller: Pingxiang Naike Chemical Equipment Packing Co.,Ltd. | Berl ring is an earlier saddle-shaped packing, shaped like a saddle. Berl ring is also called Ber... | |

| ACTIVATED MOLECULAR SIEVE POWDER | Seller: Pingxiang Naike Chemical Equipment Packing Co.,Ltd. | Activated Molecular Sieve Powder Activated Molecular SievePowder is dehydrated synthetic powde... |