Automatic oxidation stabilitytester of lubricating oil (Rotary bomb oxidation method) FDH-0171

FDH-0171 Oxidative stability tester of steam turbine oil (rotating pressure vessle method)1, lubricating oil oxidation stability analyzer (rotary bomb method) liquid sealing technology imports bi-directional rotation, so that the pressure sensor and oxygen bomb connected to common rapidly rotating colleagues and wired access input signal, different from the traditional brush slip ring, no wear, the signal is not distorted, durable

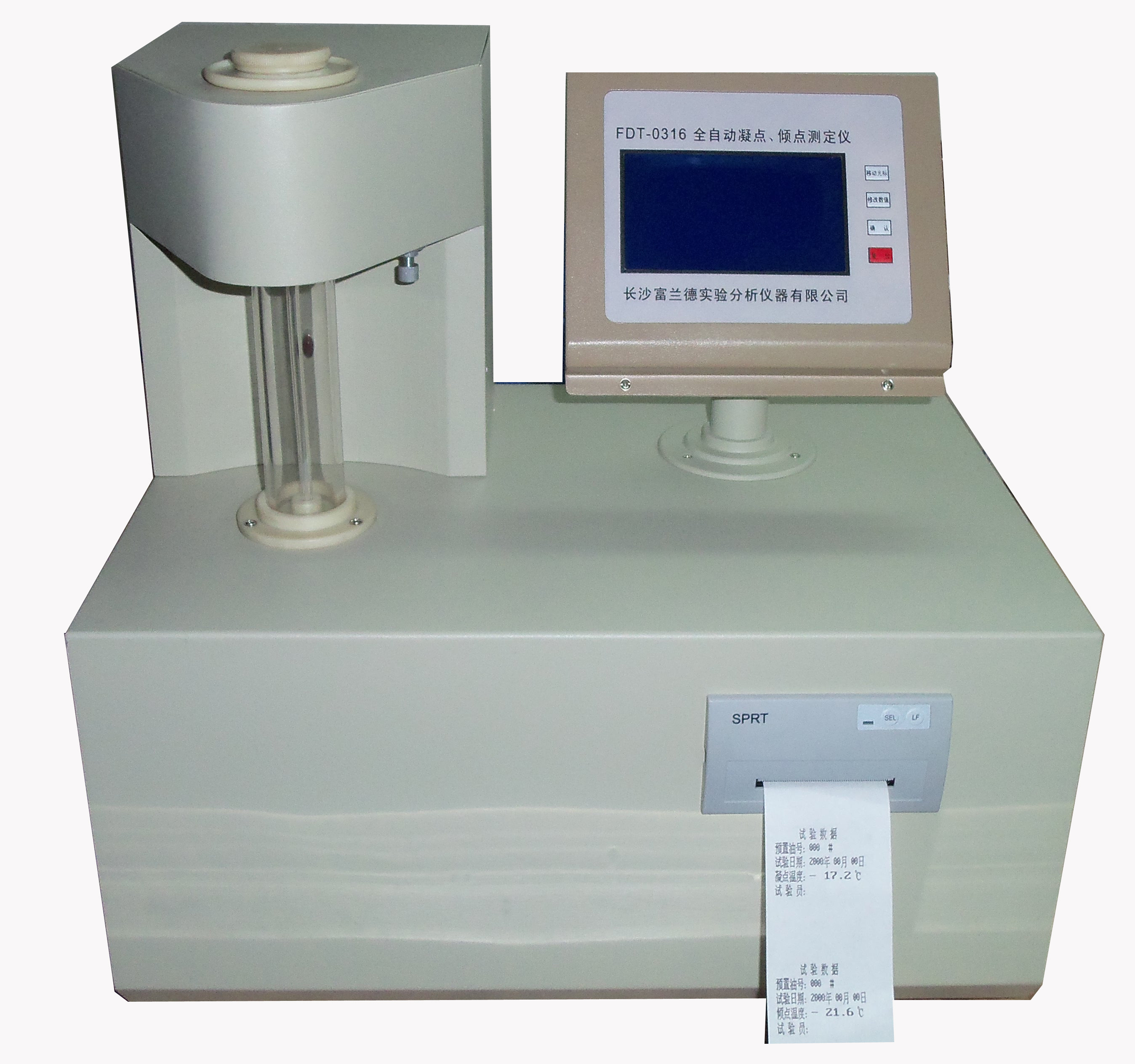

2, the lubricant oxidation stability analyzer (rotary bomb method) using large-screen color LCD display, and user-friendly design with height and tilt viewing angle can be adjusted, you can adjust the LCD screen at any time according to the needs and habits of different operators, height and tilt viewing angle for operation and monitoring equipment, to meet the needs of individual customers

3, lubricating oil oxidation stability analyzer (rotary bomb method) using the automatic touch sensing system for man-machine communication communications, continue to meet the customers the advanced nature of the instrument, ease the need for

4, the lubricant oxidation stability analyzer (rotary bomb method) realize the automatic operation, the whole process without human duty, automatic detection, auto-oxidation curve display, automatic storage and print test results

5, the lubricant oxidation stability analyzer (rotary bomb method) has a menu prompt operation, data processing, data storage, fault self-diagnosis, print

6, the the lubricant oxidation stability analyzer (rotary bomb method) using the embedded operating system run more stable, more humane

7, lubricating oil oxidation stability analysis (rotary bomb method) innovative use of security system, great to avoid and prevent the risk of accidents due to the long hair of the operator and other belongings with oxygen bomb rotary stirring (the company's first, welcomed by the laboratory operator)

8, the lubricant oxidation stability analyzer (rotary bomb method) using a circuit protection system, to avoid excess current or voltage instability caused by damage to the instrument, to the maximum extent possible to ensure the safety

Technical parameters

1, Power: AC220V ± 10%.

2, the heating tube power: 2500W.

3, the pressure sensor range: 0 ~ 1.6MPa Accuracy: ± 2%.

4, the oil bath temperature range: room temperature ~ ~ 200.0 ° C continuously adjustable, 150.0 ° C commonly used.

5, temperature control accuracy: ± 0.1 ° C.

6, two bombs, at the same time do the two samples, to facilitate the parallel trial.

7, the rotation mechanism speed: 100 ± 5r/min.

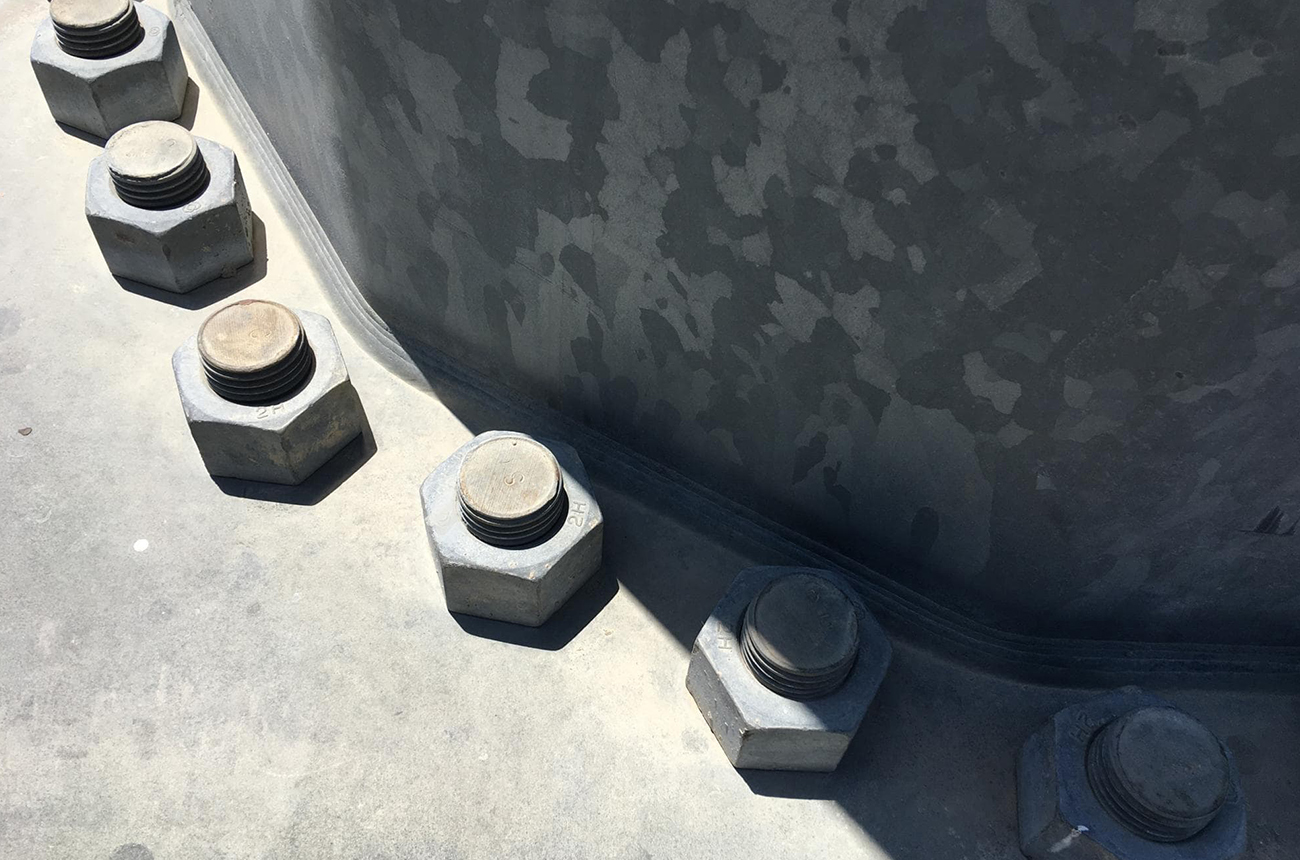

8, oxygen bomb and the horizontal angle: 30 °.

9 Dimensions: 664x574x920

10, an oil bath volume: 30L

11, Weight: about 45Kg

Other supplier products

All supplier products

Same products