STEEL STRUCTURE PAINT

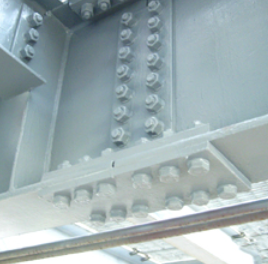

Steel Structure Coating

The anti corrosive paint for steelstructure buildings is mainly made according to ISO12944, including serving life, corrosion environment, structural design, surface treatment, coating system, coating product performance, construction supervision and the solution plan of maintenance support.

When designing a steel structure anti corrosive coatings system, the first thing is to determine the corrosion environment of the steel structure, then determine the required service life of the anti-corrosive paints, and finally determine the supporting plan of the anti-corrosive paints, including the product type and the thickness of the paint film.

According to the definition of corrosive environment in ISO12944-2, remote areas, low-pollution areas, and environment inside buildings with heating are C1 and C2 environments. In urban and industrial environments, the moderately polluted area is the C3 environment. Industrial areas, coastal areas, chemical plants and other places with high pollution or salt spray can be regarded as C4 environments. High-humidity industrial areas and places with particularly severe pollution can be identified as C5-I industrial corrosion environments. High humidity and high salinity are C5-M marine corrosion environments.

Types of Steel Structure Paint

High Build Aliphatic Polyurethane Paint

High Build Epoxy Anticorrosive Paint

Fast Dry Alkyd Antirust Primer (Iron Red, Gray)

Acrylic Finish

Alkyd Enamel Paint

Alkyd Surface Tolerant Antirust Paint

Acrylic Alkyd Finish

Features of Steel Structure Paint

Anti-rust primer

In the anti-corrosion coating system of steel structure, the role of anti-rust primer is very important. Commonly used anti-rust primers include epoxy zinc-rich primer, inorganic zinc-rich primer and thick build modified epoxy paint.

The function of the intermediate paint is to increase the thickness of the coating to improve the shielding performance of the entire coating system. The most commonly used intermediate paint is epoxy mica iron oxide intermediate paint.

The main function of the topcoat is to shield the sun's ultraviolet rays and the destructive effect of the air pollution on the coating, resist wind, snow and rain, and have a good decorative property. Highly weather-resistant anti-corrosion topcoats on the surface of steel structures are mainly acrylic polyurethane topcoats, fluorocarbon topcoats and polysiloxane coatings.

ISO12944-2

According to the definition of corrosive environment in ISO12944-2, remote areas, low-pollution areas, and environment inside buildings with heating are C1 and C2 environments. In urban and industrial environments, the moderately polluted area is the C3 environment. Industrial areas, coastal areas, chemical plants and other places with high pollution or salt spray can be regarded as C4 environments. High-humidity industrial areas and places with particularly severe pollution can be identified as C5-I industrial corrosion environments. High humidity and high salinity are C5-M marine corrosion environments.

ISO12944-1 divides the design service life of anticorrosive coating system into three durability ranges.

1) Low durability, design life is less than 5 years.

2) Medium durability, design life is 5-15 years.

3) High durability, design life is more than 15 years.

The steel structure building requires a high service life, so for the steel structure coating system, a high durability service life is also required. Therefore, the structural paint design for steel structure buildings is more than 15 years, or even more than 25 years.

We also have kinds of polyurethane based paintfor sale, if you have any needs, please leave us a message.

Send product request

Other supplier products

| Chlorosulfonation Polyethylene Anticorrosive Primer | Chlorosulfonated polyethylene primeris formulated with chlorosulfonated polyethylene resin, anti-corrosive and antirust pigments, fillers and addit... | |

| Chlorinated Rubber Antifouling Paint (For Ships) | Chlorinated rubber paint for boatsis a long-lasting ship bottom antifouling china paintformulated with chlorinated rubber, plasticizer as the base ... | |

| Waterborne Acrylic Coating | The water based acrylic coatingis composed of acrylic emulsion, pigments, etc. The water borne acrylictopcoat is a one-component coating with water... | |

| FUXI ® ANTISTATIC PAINT | FUXI ® ANTISTATIC PAINT The anti static coating for metalis used for the inner wall of the oil tank. The basic function is to protect the stee... | |

| PIPELINE COATING | Internal coating of pipelinesis an economical and practical practical solution to maintain pipeline, which can provide continuous protection for th... |

Same products

| Mara Stone Texture Paint for Blue Kingfisher Designs | Seller: Zhongshan Blue Kingfisher New Environmental Protection Materials Co., Ltd | Product Overview BlueKingfisher Gamazine Paintis an innovative artistic coating material. Formul... | |

| CUSTOM COLOR SPRAY PAINT (RAL & PANTONE) | Seller: Shenzhen Sunrise New Energy Co.,Ltd. | 7CF® custom color aerosol spray paintis made from thermoplastic acrylic resin and the custom ... | |

| CRYSTAL WAX | Seller: Shenzhen Sunrise New Energy Co.,Ltd. | 7CF® Crystal Wax Car Polishis a high-quality super deep care crystal emulsion made of advance... | |

| POLISH WAX | Seller: Shenzhen Sunrise New Energy Co.,Ltd. | 7CF® car body wax polish wholesale rejuvenates dull or faded paintwork, restoring it to a dee... | |

| ACRYLIC SPRAY PAINT | Seller: Shenzhen Sunrise New Energy Co.,Ltd. | As one of the leading aerosol spray paint company, 7CF provides high-preformance Acrylic Spray Pa... |