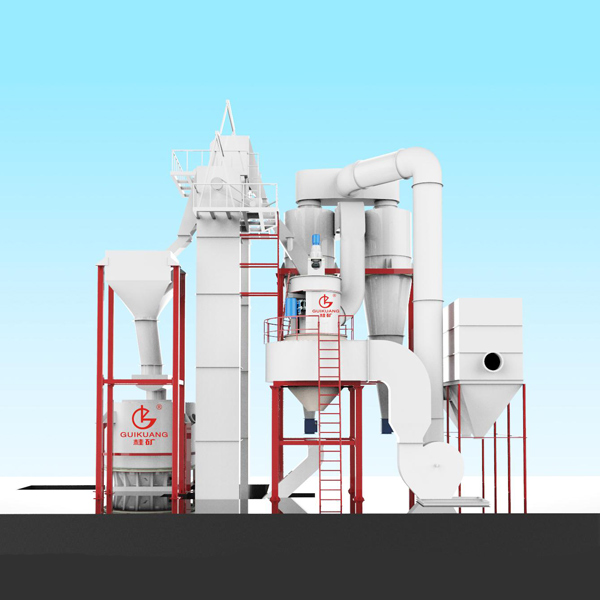

Grinding Mill

|

Grinding Mill Grinding mill is mainly used in building materials, chemical industry, chemical fertilizer, metallurgy, mining, refractory, ceramic, steel, thermal power, coal and other industries, and it is suitable for the non flammable and explosive mineral materials that the grinding Mohs hardness is below 9 grade and moisture is under 6%. Fineness of finished products can be adjusted arbitrarily in 30 orders to 400 orders. In view of the current development trend and market demand of the domestic grinding industry, a new type of ultra-finegrinding machine for saleis invented for users with special needs. It is mainly suitable for calcite, Cretaceous, calcium carbonate, dolomite, kaolin, bentonite, talcum, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate rock, potassium ore, pumice, and so on. It is not inflammable and explosive nonmetallic materials that the Mohs hardness is below 9 grade and moisture is under 6%.There are,,,,,and also include vibration Feeder (feeder), bucket elevator, conveyor, conveyor, etc.Summary of points for attention:1.In the process of using the grinding mill, there should be fixed personnel to take charge of it, and the operator must have certain technical level. The necessary technical training should be taken to the operator before installation of grinding mill, so as to understand the principle and performance of the grinding mill. Let them be familiar with the operation regulations and choose the right equipment for the customers according to the actual situation. The field installation and the training of the operator should be carried on at the same time.2.In order to make the grinding mill operating normal, we should make rules and regulations called equipment maintenance safety operation system, which will ensure the long-term safe operation of the mill. At the same time, necessary maintenance tools, grease and corresponding accessories should be equipped.3.After a period of time, the grinding mill should be checked and the worn parts such as the roller mill ring scraper should be repaired or replaced. The connecting bolt nuts should be examined carefully before and after using the roller device to see if there is any loose phenomenon and whether the grease is enough.4.When the grinding roller is used more than 500 hours, it should be replaced. The rolling bearings in the roller sleeve must be cleaned, and the damaged parts should be replaced in time. The tools for filling up fuel can be used by manual gas pump and grease gun. |

Send product request

Other supplier products

| Impact Crusher | The Application and Usage of Impact Crusher: Impact crusher is suitable for materials whose compressive strength is under 350Mpa, and particle size... | |

| Pendulum Grinding Mill | Pendulum millis also called as suspension roller or Raymond mill. It is a "ring and roller" powder-making mill equipment, which is combined with ai... | |

| GK-PSC Type Water Spray Precipitator | This equipment is one of the necessary equipment for the lime digester. GK-PSC Type Water Spray Precipitator characters: It adopts natural water c... | |

| GKC Series Energy-Saving Super-Large Grinding Mill | After years of research and experiment, we have designed the newest GKC series super-large energy saving grinding equipmentwith high efficiency. GK... | |

| Vertical Grinding Mills | GKLM series vertical grinding mill is one advanced powder grindingmillthrough our engineer research and experience and bringing in advanced techno... |

Same products

| HM Pumex Grinding Machine | Seller: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| XZZ Z1 Pro Electric Grinder Pen IC Polish Tool | Seller: ShenZhen VIP FIXPHONE Technology Co., Ltd, | XZZ Z1 Pro Electric Polishing Pen with Various Grinding Heads for different types of grinding and... | |

| Scraper Grinding Machine | Seller: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| Compact Electric Grinding Pen for IC Polishing | Seller: PHONEFIX Technology Co., Ltd. | Description E288-02 small handheld grinding machine mini motherboard CPU IC polishing pe... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | Seller: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |