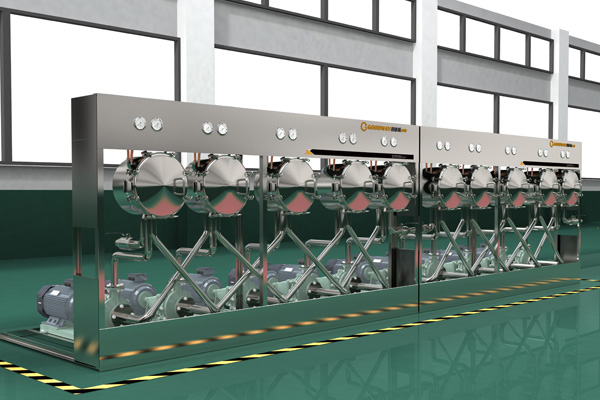

Sweet Potato Starch Machine

Sweet Potato Starch Process Description and Flowchart:

Goodway has been continuously developing sweet potato starch machine since 1991 to maximize product quality. From sweet potato root hopper until the packaging stage, we can supply potato powder making machinetogether with production process know-how.

The production process of sweet potato starch comprises the steps such as delivery and unloading sweet potato, washing, crushing, slurry and residues separation, desanding & desilting, starch concentrating and refining, de-watering, starch drying, and packaging. We provide below a brief description of the main steps of the sweet potato starch productionprocess.

Note: Goodway updates the sweet potato starch machine and sweet potato starch processing production line technology and machinery based on the latest experience. Sweet potato washing machine is also available.

Cleaning and Washing Sweet Potato Roots

Wash the fresh sweet potato roots in clean water to remove the surface mud and sand. It's the first step of sweet potato starch process and very important for the quality of final sweet potato starch.

Crushing Washed Sweet Potato Roots into Slurry

Crushing the washed sweet potato roots into the slurry and separate to remove the coarse sweet potato residues to obtain uniformly smooth sweet potato slurry. The crushing drum and all food contact areas should be made from stainless steel.

Sweet Potato Slurry and Residues Separation

The commonly physical operation to separate fine sweet potato residues from sweet potato slurry. Oversize particles of sweet potato residues cannot pass through the lattice structure of the filter, while fluid and small particles of sweet potato slurry can pass through to become filtrate.

For more about how to make sweet potato starchand potato processing line, contact us.

Send product request

Other supplier products

| Cassava Peeling Machine | Features of Cassava Peeling Machine Processing Capacity: 4-6Tons/hourApplication Scope: Fresh cassava peeling and washingProduct Introduction: Cas... | |

| Cassava Peeling Machine | Cassava Peeler Design Features of Cassava Peel Processing Machine Processing Capacity: 4-6Tons/hour Application Scope: Fresh cassava peeling a... | |

| Cassava Garri Fryer | Features of Cassava Garri Fryer Processing Capacity: 100-300kgs/hour Application Scope: Garri frying or roasting Product Introduction: garri fryer,... | |

| Sweet Potato Starch Machine | Features of Sweet Potato Starch Machine Sweet Potato Starch Machine Sweet Potato Starch Process Description and Flowchart: Goodway has been co... | |

| China Potato Peeling Machine | With the development of food industry, food deep processing has been paid more and more attention by the world, especially in the birth of instant ... |

Same products

| STSP2 Type Servo Straight Side Double Points Press for Automotive Sectors | Seller: Suzhou S-T Intelligence Technology Co., Ltd | Shop S-T Intelligence's high-quality double-point servo presses, ideal for complex stamping and f... | |

| TITANIUM SHEET | Seller: Gallianz (Anhui) New Materials Co., Ltd. | TITANIUM SHEET Titanium is known as "the metal of the future". At present, some people call tita... | |

| STAINLESS STEEL SHEET | Seller: Gallianz (Anhui) New Materials Co., Ltd. | STAINLESS STEEL SHEET Stainless steel (ss) is an alloy, which is iron-based and contains various... | |

| STAINLESS STEEL CLAD PLATE | Seller: Gallianz (Anhui) New Materials Co., Ltd. | STAINLESS STEEL CLAD PLATE The carbon steel sheet is bonded with stainless steel sheet on one or... | |

| SPECIAL METAL SHEETS | Seller: Gallianz (Anhui) New Materials Co., Ltd. | SPECIAL METAL SHEETS Looking for a special steel platemanufacturer? Welcome to Gallianz Group! B... |