Automotive Interior – Reactive Polyurethane Hot Melt Adhesive (PUR)

Automotive Interior Polyurethane Adhesive: Innovation in Vehicle Design

Polyurethane (PU) adhesives have revolutionized automotive interior assembly, offering unmatched versatility and durability for bonding diverse materials. Below is a concise overview of their key features and applications.

Key Advantages

Material Compatibility: Bonds plastics, fabrics, composites, and metals—critical for modern multi-material interiors.

High Strength & Flexibility: Maintains structural integrity under vibration and temperature fluctuations.

Rapid Curing: Enables faster production cycles without compromising adhesion quality.

Technical Specifications

| Parameter | Typical Value |

|---|---|

| Cure Time (25°C) | 15–30 mins (initial set) |

| Operating Temp Range | -40°C to +120°C |

| Peel Strength | >50 N/cm (on steel) |

| Viscosity | 5.000–15.000 cPs |

| VOC Content | <2% (compliant with regulations) |

Applications in Automotive Interiors

Dashboard Integration: Bonds soft-touch foams and decorative trims.

Seat Construction: Adheres leather/fabric covers to foam padding.

Door Panels: Secures armrests, speakers, and insulation materials.

Headliners: Provides strong yet lightweight attachment to roof structures.

Sustainability & Compliance

Modern PU adhesives are formulated for low VOC emissions and recyclability, aligning with automotive OEM sustainability goals. They meet stringent automotive standards (e.g., ISO 1182 for fire retardancy).

Conclusion

Polyurethane adhesives are pivotal in enhancing automotive interior design, enabling lighter, safer, and more aesthetically pleasing cabins. As electric vehicles prioritize weight reduction, PU adhesives will remain a cornerstone of advanced assembly solutions.

Send product request

Other supplier products

| Adhesive for micro speakers | With the development of electronic products, speakers are developing in the direction of small cavity, ultra-thin, high sound quality, and high pow... | |

| Rheology modifier STD-9010 | Composition: Polyurea mixture solution Appearance: yellow transparent solution Active ingredient: 50% Solvent: N-methylpyrrolidoneScope of Appli... | |

| PVF steel drum coating | Introduction PVF steel drum coating is mainly used for packaging containers of chemical pesticide products, inner walls of cans and other special ... | |

| Sealing application adhesive | Introduction Polyurethane and epoxy resin materials, different models of products can provide targeted insulation strength, flame retardant perfor... | |

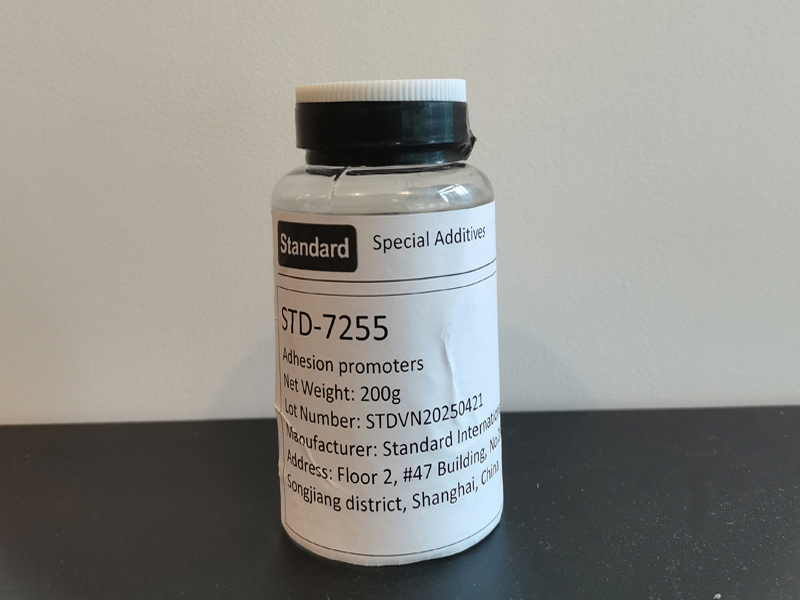

| Adhesion promoters STD-7255 | Description STD-7255 is a linear polyester with active hydrogen atoms adhesion promoter. It is suitable for self dry solvent coating systems. STD... |

Same products

| Epoxy/Polyester Powder Coatings | Seller: Standard International Group (HK) Limited | Feature: -Good bond ability and mechanical performance -Smooth and glossy -Certified chemical ... | |

| Polyester Clear Powder Coatings | Seller: Standard International Group (HK) Limited | This series of product are made of polyester resin (as hardener) and highly transparentmaterials.... | |

| Acrylic Clear Powder Coatings | Seller: Standard International Group (HK) Limited | Feature: -Excellent exterior exposure durability -Excellent durable high gloss -Excellent clar... | |

| Polyurethane Powder Coatings | Seller: Standard International Group (HK) Limited | Feature: -Excellent exterior exposure durability -Good flowing -Excellent chemical resistance ... | |

| MDF Powder Coating | Seller: Standard International Group (HK) Limited | Feature: -Environmental friendly -No solvents and volatile organic compounds involved which are... |