Dust-free Purification Workshop Design: How Much is the Difference Between 10,000 and 100,000?

It is well known that a large number of high-tech industries are inseparable fromdust-free purification workshops, such as CCL circuit substrate copper clad laminates, PCB printed circuit boards, photoelectric LCD panels and LEDs, power and 3C lithium batteries, and some pharmaceutical and food industries. With the development of science and technology, the quality standards of supporting products required by the manufacturing industry are constantly being improved. Therefore, industrial manufacturers not only need to innovate products from the production process, but also need to improve the production environment of the products, strict requirements of the workshop environment, and improve product quality and stability.Whether it is to renovate existing plants due to improved product quality, or to expand the plant due to market demand, industrial manufacturers will face major problems related to the future of the project. From infrastructure to supporting decoration, from the process to the equipment procurement, a series of complicated and complicated project processes. In this process, the builders should pay more attention to the project quality and comprehensive cost. The following are some of the major factors that affect the cost of a cleanroom in an industrial plant:First, the space factor:The space factor consists of two areas: workshop area and workshop height. It directly affects the cost of interior decoration: color steel partition wall and ceiling area; air conditioning input cost: area volume of air conditioning load required, air conditioning return air way , the pipeline direction of the air conditioner and the number of air conditioner ends.To avoid the increase of project investment due to space reasons, the builders can consider two aspects: the working space of different production process equipment (including the height or width of movement, maintenance and repair); the space of work flow and logistics. At present, the building follows the principles of land saving, material saving and energy saving. Therefore, the purification workshop is not as high as possible. When considering the construction process equipment and processes, it can effectively avoid unnecessary investment costs.Second, temperature, humidity and cleanliness factors:Temperature, humidity and cleanliness are standard environmental data of workshops tailored for industrial products. It is a high design basis for purification workshops and an important guarantee for product qualification and stability. The current standards are divided into national standards, local standards, industry standards, and internal corporate standards. For example, the cleanliness grade classification standard and the pharmaceutical industry GMP standard belong to the national standard. For most manufacturing industries, the standard of each production process purification workshop is determined mainly according to the characteristics of its own products. For example, the PCB industry's exposure, dry film, solder mask temperature and humidity at 22 ± 1 ° C, 55 ± 5%, cleanliness ranging from 1,000 to 100,000; lithium battery industry is more focused on low humidity control, generally relative The humidity is below 20%, and some fairly strict injection workshops need to be controlled at about 1% relative humidity.Defining environmental data standards for purification plants is a central point that is critical to project investment. The establishment of cleanliness level affects the cost of decoration: it is set at the level of 100,000 and above, requiring necessary clean sheet enclosure, purifying doors and windows, personnel and cargo air shower transmission facilities, and even expensive high-priced flooring; also affecting air conditioning costs The higher the cleanliness, the greater the number of air-conditioning changes required to meet the purification requirements. The larger the air volume required to clean the wind cabinet, the more the air duct and the end efficient air outlet. In the same workshop, the temperature and humidity are not only the above-mentioned cost problems, but also the factors that control the accuracy. The higher the accuracy, the more complete the necessary equipment. If the relative humidity range is accurate to ±3% and ±5%, the humidification equipment and dehumidification equipment to be designed must be complete.The formulation of temperature, humidity and cleanliness of the workshop not only affects the investment in the early stage, but also the operating cost of the later stage of a long-term factory. Therefore, according to the characteristics of the products produced by the company, combined with the national standard, the standard and the internal standards of the enterprise, Reasonable development of environmental data standards that meet their own needs is a fundamental step in the preparation of a clean plant foundation.Third, other influencing factors:In addition to the space and environment requirements, some factors affecting the compliance of the purification workshop are often ignored by the design or the builder, resulting in excessive temperature and humidity. For example, the external climate considerations are not comprehensive, the amount of equipment exhausted is not considered, the heat generated by the equipment is not considered, the amount of dust generated by the equipment is not considered, and the amount of moisture produced by a large number of people at the same time is not considered.In summary, how much is the difference between 10,000 and 100,000? Before asking this question, it is reasonable to first define the parameters (length, width, height, displacement, heat generation, dust production) of the production equipment in the purification workshop, and formulate the workshop area, floor height, temperature and humidity to meet their own needs. Cleanliness requirements, and then the design side to design a reasonable comprehensive purification program. As a builder, not only is it fully aware of its own needs, but it can also be used to control the quality, cost and schedule control of the entire project design, procurement, construction, acceptance, and trial production.If your are thinking about, WONZONE is a your reliable choice, since we have been supplying clean room construction material for a many years.

Other supplier products

|

|

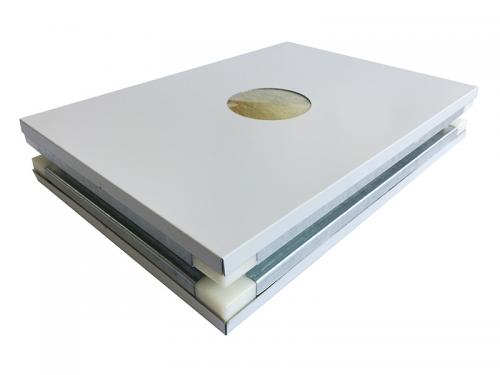

Clean Room Sandwich Panel |

Clean room polyurethane sandwich panelsare main products in clean room engineering, which are flame retardant, soundproof and environmentally frien... |

|

|

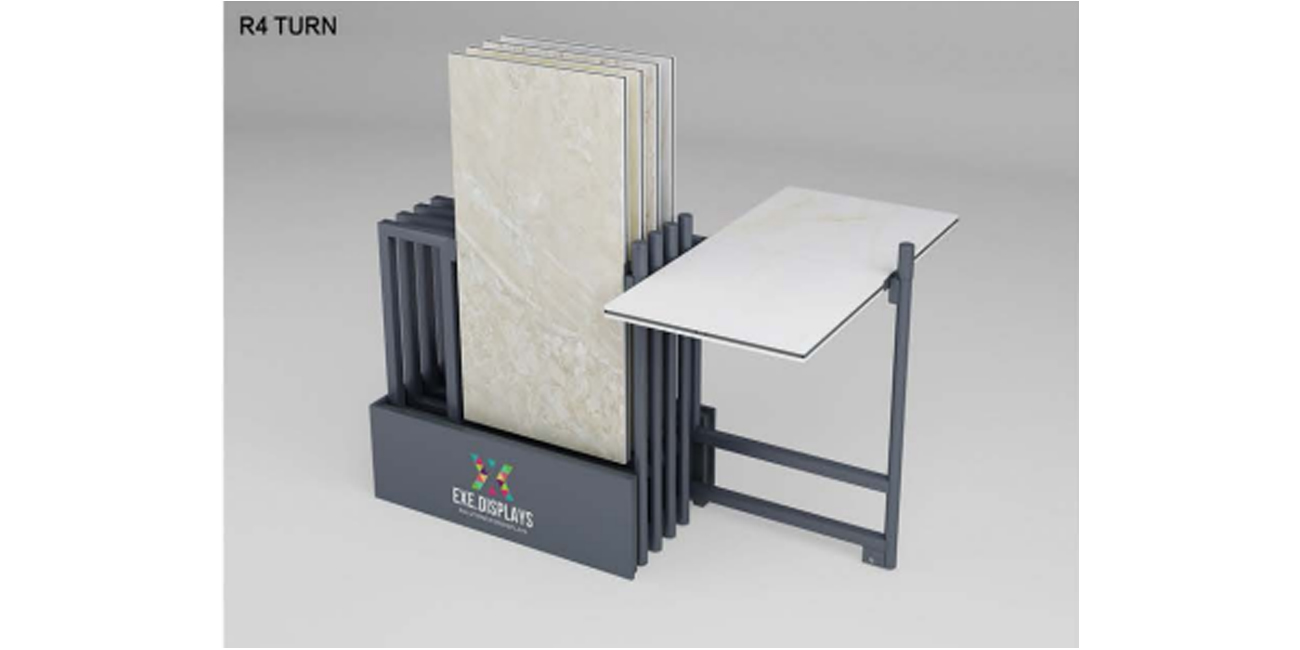

Clean Room Steel Door |

Overview

Our(clean room doors and windows factory) steel door products are made of steel frame and PCGI door panels with very good flatness and fir... |

|

|

Dust-free Purification Workshop Design: How Much is the Difference Between 10,000 and 100,000? |

It is well known that a large number of high-tech industries are inseparable fromdust-free purification workshops, such as CCL circuit substrate co... |

|

|

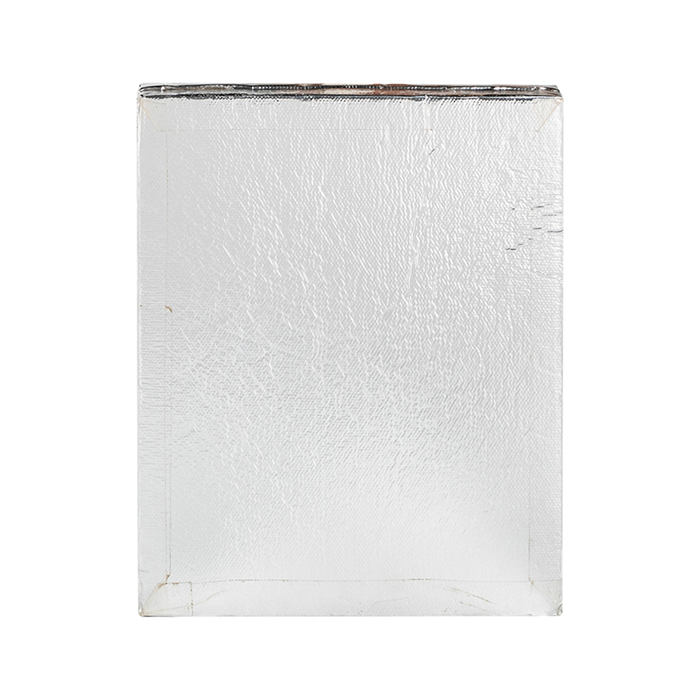

Honeycomb Sandwich Panel |

Overview

Honeycomb core introduction: Aluminum hexagonal honeycomb, with low density, 1/5 of the same thickness of the same board, 1/6 of the glass... |

|

|

Air Shower |

Overview

When people and goods enter the clean area, they need to be blown through the . The clean air can remove the dust carried of people and go... |

All supplier products

Same products