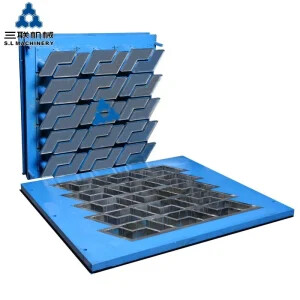

SLST3000 Large Hydraulic Ecological Wall Production Line

SLST3000 Large Hydraulic Ecological Wall Production Line

In 2022, Sanlian Machinery launched the SLST2400 super large-scale hydraulic brick production equipment, primarily targeting the production of large-scale hydraulic bricks and retaining wall blocks with a molding area of up to 1500x1300x600mm. By 2024, Sanlian Machinery achieved another technological breakthrough, producing the largest domestic hydraulic bricks and retaining wall blocks with sizes up to 1900x1320x800mm,the device model has been upgraded from SLST2400 to SLST3000.

How to maintain the SLST3000 Large Hydraulic Ecological Wall Production Line?

- 2. Check the oil level and oil quality to ensure that the hydraulic oil is clean and free of impurities, and the oil level is within the indicated range. Replace the hydraulic oil regularly. It is generally recommended to replace it every six months or according to the frequency of use and the condition of the oil.3. Check whether the electrical system is normal and whether the line is worn or exposed.4. Clean the dust and residual materials on the production line regularly to prevent blockage and corrosion.Clean the mold to ensure the molding quality and avoid product defects caused by unclean molds.5. Check and clean the filter of the hydraulic system to prevent blockage from affecting the smooth flow of the oil circuit.6. For moving parts such as bearings, guide rails, gears, etc., add lubricating oil or grease regularly to reduce wear and keep smooth operation.7. Regularly check and tighten all screws, bolts and other fasteners to prevent loosening due to vibration.8. Regularly check the working status of hydraulic components such as hydraulic pumps, valve bodies, and cylinders, and replace severely worn seals and wearing parts in time.9. Monitor the operating temperature of the hydraulic system. If it is too high, check whether the cooling system is working properly.

Technical Parameters

|

Model |

SLST3000 |

|

Pallet Size(mm) |

2400*1400 |

|

1900*1320 |

|

|

Product Height(mm) |

45-800 |

|

Production Mode |

pure vibration |

|

Servo Drive Shaft |

8 |

|

Main Oil Cylinder Tonnage/T |

28 |

|

Excitation Force/KN |

550 |

|

lf the required pallet size or product heights are not listed here, we are happy to make special plans for you. |

|

Production Table

|

Brick Size |

Production (Per mould) |

Production (8h one shift) |

|

Hollow Brick 390x190x190mm |

21 |

≈40,000 PCS 560m³ |

|

Solid Brick 240x115x53mm |

120 |

≈288,000 PCS 420m³ |

|

Paver 200x100x60mm |

78 |

≈112,300 PCS 2200m² |

|

Difference between different raw material and ratio and production modeIf a cuber is required,the capacity may be affected |

||

Send product request

Other supplier products

| Vertical Shaft Planetary Mixer – High-Efficiency Mixing for Premium Cement Products | The Vertical Shaft Planetary Mixer is specially engineered for precision mixing of high-end concrete products, such as sponge permeable ecological ... | |

| Vertical Wall Panel Production Line – EPS with Calcium Silicate Board | The Vertical Type EPS Wall Panel Machine combined with calcium silicate board technology is a high-efficiency system for producing lightweight, the... | |

| Batching Machine – Precision & Automation for Concrete Production | The Batching Machine is a critical component in block production lines, ensuring precise material dosing, automated control, and smooth integration... | |

| Economic Mobile Portable Dry Mix Batching Plant | The Transit Mixing Batching Plant uses a mixing truck in place of a twin-shaft mixer to produce concrete. It consists of an aggregate hopper, belt ... | |

| China cement block making machine suppliers | Cement Block Making Machines: Revolutionizing Cost Efficiency in Construction Modern cement block making machines have transformed construction by ... |

Same products

| KBL Machinery Pavement Moulding for Sale | Seller: Quanzhou Kimberly Machinery Manufacturing Co. Ltd | KBL Machinery’s pavement moulding machines are reshaping construction by enabling fast, pre... | |

| China Cement Paving Mould Supplier | Seller: Quanzhou Kimberly Machinery Manufacturing Co. Ltd | KBL Machinery is redefining eco-conscious construction with its energy-saving cement paving mould... | |

| KBL Machinery’s Paving Cement Mold Supplier | Seller: Quanzhou Kimberly Machinery Manufacturing Co. Ltd | As the demand for smarter and more sustainable construction grows, paving cement molds from KBL M... | |

| China Path Mold Supplier | Seller: Quanzhou Kimberly Machinery Manufacturing Co. Ltd | As a top-tier path mold supplier, KBL Machinery delivers advanced solutions for paving production... | |

| KBL Machinery's Stone Mould Supplier | Seller: Quanzhou Kimberly Machinery Manufacturing Co. Ltd | KBL Machinery is a reliable supplier of stone moulds, offering durable and high-performance solut... |