PVD COATING

Physical vapour deposition, just PVD coating, as we usually call it, refers to vacuum ion plating and vacuum sputter plating; Generally speaking, ncvm coating refers to vacuum evaporation coating. The basic principle of PVD surface treatmentis to vaporize the coating material under vacuum, and then deposit it evenly on the surface of the target part through electrons. The advantages of PVD are: good adhesion of coating (good mechanical properties), strong winding ability (adjustable target position and electroplating path), good coating quality (dense, uniform, high strength and long service life), simplified cleaning process (with cleaning function), and a wide range of plating materials (metal and non-metal can be plated).

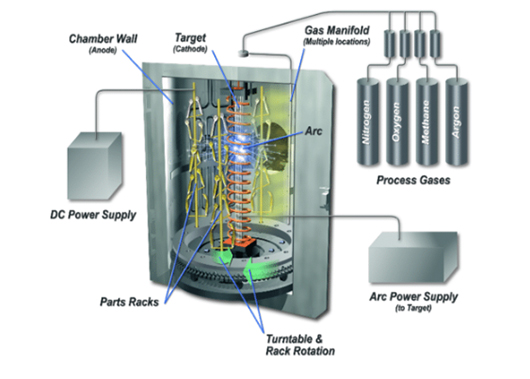

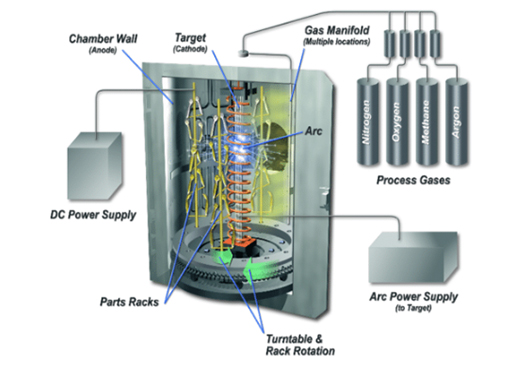

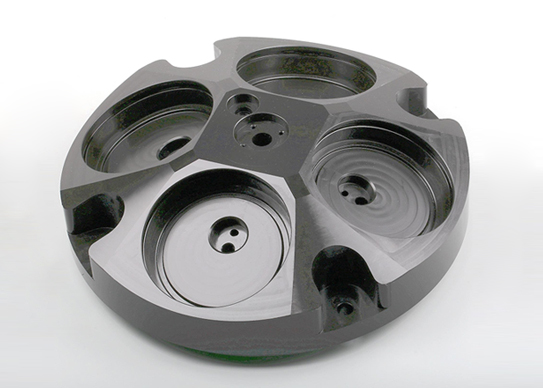

PVD Coating System

custom pvd coatingpvd coating systempvd coating technology

Does PVD Coating Wear Off?

The wear resistance of PVD coating system is different with different electroplating materials. For example, the CRN coating on the surface of bearings and cutting tools has strong wear resistance and is not easy to wear off.

Is PVD Better Than Stainless Steel?

PVD Physical Vapour Deposition is a surface treatment process. PVD surface treatment aims to improve or improve the performance and appearance of metal surfaces, and cannot be compared with the performance of cheap CNC material.

Types Of PVD Coating

There are different types of PVD coatings that can be offered depending on the application requirements. Titanium Nitride (TiN), Chromium Nitride (CrN), Titanium Aluminum Nitride (TiAlN), Titanium Boron Nitride (TiBN) are some examples of PVD coatings.

PVD CoatingAdvantages

Physical vapour deposition coatings offer the following benefits:

PVD surface treatment has high hardness (2400-4000 HV) (~ 80-90 HRc).

PVD physical vapour deposition is high abrasion resistance.

PVD metal coating is low friction coefficient (high surface lubricity)

Reduced tool heating due to low thermal conductivity of PVD physical vapor deposition.

Physical vapor deposition coating is well resistance to chemical environments

PVD metal finishcan increase surface quality of the machined parts

Preventing the processed parts from adhering to the tool-mold surface

No change in dimensions due to PVD coating thickness at micron level

Decrease in tool cost per piece due to increased tool physical life

Decreasing in workbench downtime periods since tool change frequency are decreased

PVD surface treatment can obtain homogeneous coating thickness in each area

PVD Coating Technology

PVD coatings can be applied on components using different PVD technologies such as arc evaporation, magnetron sputtering to name a few. HEF specializes in plasma enhanced magnetron sputtering, CAM (coating assisted by microwaves) and modified arc evaporation coating technologies. PVD coating technology is the most important one of the methods in which hard ceramic coatings can be successfully applied on mold and tool surfaces. This PVD technology is based on the principle of ionic accumulation of materials under vacuum by being evaporated and/or sputtered on the surface, to which the coating is to be applied.

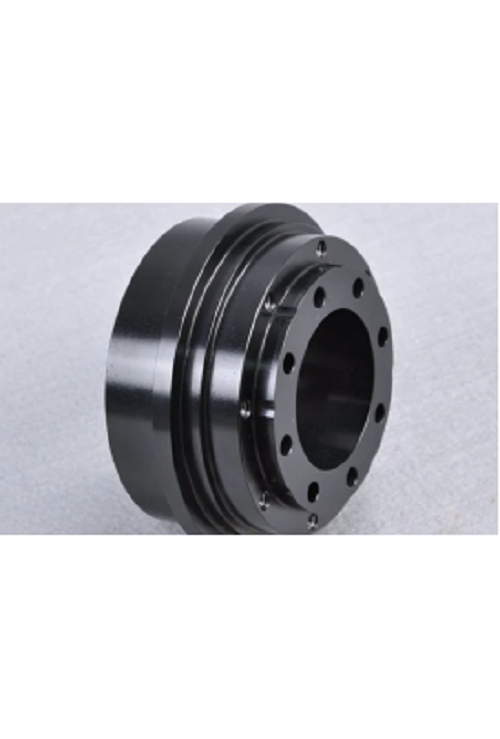

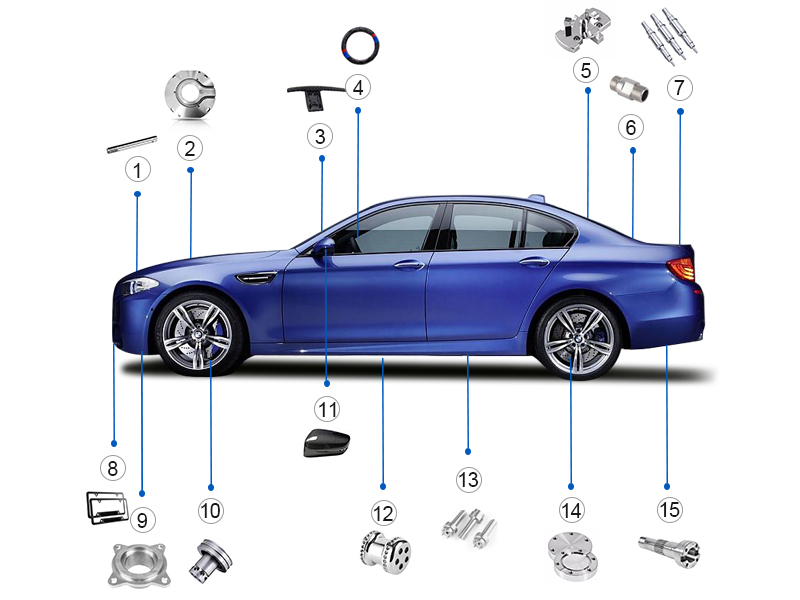

PVD Coating Applications

PVD coating can be found in a broad range of products. For example, PVD surface treatment is frequently used in architecture. There is a wide range of PVD coating applications, which is why it is commonly used in high-tech industries. Some of the industries and applications in which we have applied PVD physical vapor deposition coating include coating on composites for aerospace, titanium on medical implants and surgical tools, gold thin film to replace plating for electronics, non-metal, chemical resistant oxides for semiconductor parts and hard ceramic coatings for industrial tools.

PVD Coating Thickness

In general, PVD surface treatment is thin film and are in the range of 1 to 5 microns. For reference, 25 microns equals 0.001 inches. Red blood cells are around 8 microns in diameter, while human hair is around 80 microns in diameter. Thus, PVD coatings are extremely thin-film coatings with thickness specification defined within this 1 to 5-micron range depending on the application requirement.

PVD Coating Hardness

PVD physical vapor deposition coatings have a hardness value around 1500 – 4500 HV (Vickers) depending on the types of PVD coating offered. Vickers (HV) is a microhardness unit for measuring PVD thin film coatings. For reference, 900 HV corresponds to 67 HRC (Rockwell C) hardness. Generally, carbon steels have a hardness range around 250 HV (25 HRC), nitrided or nickel and chrome plated steels fall in the range of 600 HV to 1000 HV surface hardness. Thus, PVD coatings are extremely hard and hence, very durable and wear resistant.

Shenzhen Richconn Technology Co,. Ltd , as a cnc china company, was established in 2012 and has two processing bases in Shenzhen and Dongguan, Guangdong, of which the Shenzhen base covers an area of 5000 square meters and the Dongguan base covers an area of 3000 square meters.

Send product request

Other supplier products

| Black Oxide Services | At Richconn, we rely on rack and suspend technology to provide black oxide coating services that are delivered quickly and meet high quality standa... | |

| AUTOMOTIVE CNC MACHINING | We provide OEM / ODM incremental services and supporting services for customers to grow together according to the customer characteristics of the a... | |

| PVD COATING | PVD COATING Physical vapour deposition, just ar PVD coating, as we usually call it, refers to vacuum ion plating and vacuum sputter plating; Gener... | |

| CNC PLASTIC MACHINING | The characteristics of plastic cnc machining chinamaterial are defined by the melting point temperature (150 ° to 450 °) and the use enviro... | |

| POWDER COATING SERVICES | Richconn offers customized powder coating services for your metal parts that are non-stick, abrasion resistant, corrosion resistant, insulating, lu... |

Same products

| LDC-350B Automatic Label Die Cutting Machine | Seller: RUIAN LOYAL MACHINERY CO.,LTD | LDC-350B Automatic Label Die Cutting Machine This die cutting machine is ideal for electronic pr... | |

| LY-RS320 Semi-Rotary Die Cutting Machine | Seller: RUIAN LOYAL MACHINERY CO.,LTD | LY-RS320 SemiRotary Die Cutting Machine This label press machine is the most ideal machine for p... | |

| Flexo Printing Machine | Seller: RUIAN LOYAL MACHINERY CO.,LTD | In the 1980s, flexographic printing technology developed rapidly. The performance of flexographic... | |

| LYS-S1300/1600 High speed flexible packing film slitting machine | Seller: RUIAN LOYAL MACHINERY CO.,LTD | LYS-S1300/1600 High speed flexible packing film slitting machine This kind slitting machine is a... | |

| Die Cutting Machine | Seller: RUIAN LOYAL MACHINERY CO.,LTD | The adhesive label rotary die cutting machineis all kinds of trademarks processed into the final ... |