Aluminum Composite Panel

The aluminum plastic plate also called aluminum composite panel as a new type of decorative materials with its optional color diversity, convenient construction method, excellent processing performance, perfect fire retardancy and noble quality, quickly get the favor of people in recent years. Whether on the streets or shuttling between hotels and hotels, aluminum composite panel exists everywhere.

Aluminum composite panel consists of two distinct material ( metals and non-metallic) which retains the original composition of material (aluminum metal, nonmetal polyethylene plastic) as its main features, and also overcome the disadvantages of the original material, so as to gain more excellent properties, such as luxury, colorful decoration features, weather resistance, corrosion resistance, impact resistance, fire prevention, moisture-proof, sound insulation, heat insulation, vibrate resistance, lightweight, easy to process, easy to handle and install.

So, it is widely applied to all kinds of architectural decorations, like the ceiling, the columns, the counter, the furniture, the booth, the elevator, the elevator, the storefront, the storefront, the billboard, the wall of the building, the wall of the metal curtain.

In the developed countries, the aluminum lamentation is being used in the building of the bus, the train, the car, the sound insulation of the plane, the ship and the design of the equipment box.

The aluminum composite panel is composed of multi-layer materials. The upper and lower layers are high purity aluminum alloy panels, and the middle layer is non-toxic and low-density polyethylene (PE) core plate which is also pasted with a protective film in the front. For outdoor use, aluminum composite panel front is better coated with fluorocarbon resin (PVDF) coating. For indoor use, its front can be non-fluorocarbon resin coating.

Advantages of the aluminum composite panel:

Super-stripping degree

Aluminum composite panel adopts the new technology which improves the key technical indicators of the aluminum composite panel - peel strength into a high level. The performance of the flatness and weather ability of the aluminum composite panel has been improved correspondingly.

Material processing

The weight of each square meter of the aluminum composite panel is only about 3.5-5.5 kilograms, so it helps reduce the damage caused by the earthquake, and easy to handle. Its superior construction ability needs only simple carpentry tool to finish cutting, planing edge, bend into the arc, right angle and all other sorts of shape. The aluminum composite panel can make all kinds of changes and its installation is simple that quickly reduces the construction cost.

Excellent fireproof performance

The middle layer of the aluminum composite panel is the flame retardant material - PE plastic core material where both sides are aluminum layer extremely difficult to burn. Therefore, it is a kind of safety fireproof material which meets the fire resistance of building codes.

Impact Resistance

Strong impact resistance, high toughness, curved surface paint, strong resistance to impact. No damage will be caused even in areas with large wind and sand.

Superweather ability

Fluorocarbon paint of PVDF enables it a unique advantage in weathering. No matter in the hot sun or in the cold wind or snow, the beautiful appearance will not be affected and it will not fade for more than 20 years.

uniformly coating process

The conversion coating treatment and the technology of Henkel Film make the adhesion between the paint and the aluminum composite panel uninformed. Besides, the color is varied, so that you can have more choices to show your individuality.

Easy for maintenance

The aluminum composite panel has the obvious improvement in the anti-pollution aspect. It needs maintenance and cleaning after years using. Because of the good self-cleaning feature, only neuter cleaner and water can make plank permanent as new.

Easy for processing

The aluminum composite panel is a great material for processing and molding. What’s more, it is a good product helping improve efficiency and save time. The aluminum composite panel can be cut, grooved, band saw, drilled, processed, also can be cold bend, cold folded, cold rolled. Furthermore, in connection way, it can be riveted, screwed or glued joint.

The aluminum composite panel as a kind of high-tech composite materials products has more 30 years of history since being researched and developed in the 1960s. Its various performance is also constantly improved and enhanced. The aluminum composite panel is widely applied in the transportation industry, construction industry and some special industries, such as the advertising industry, etc. Especially in the construction industry, due to its lightweight, high strength, easy to process and install such features, you can find it everywhere.

Classifications of aluminum composite panel

1. According to the usage, the aluminum composite panel can be divided into three types: aluminum composite panel for building curtain wall, aluminum composite panel for exterior wall decoration and advertisement, indoor aluminum composite panel. There are different rules for the minimum thickness of upper and down panel in different use.

2. The aluminum composite panel has different functions, some use flame retardant profiles, so it has good fire resistance. Some of the aluminum composite panel coated with an antibacterial coating on the surface has the ability to inhibit microbial reproduction and can kill bacteria. And the aluminum composite panel utilizes antistatic coating which makes it not easy to produce static electricity which refers to a strong antistatic material.

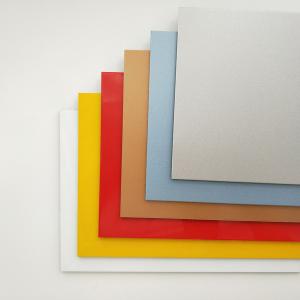

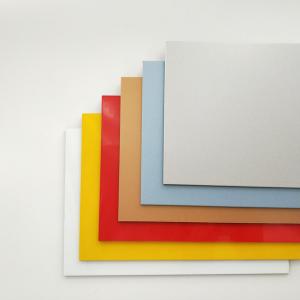

3. In addition to the function, the decoration can also be an important classification standard. According to the surface decoration effect: coating decorative aluminum composite panel, oxidation coloring aluminum composite panel, foil decoration aluminum composite panel, color printing aluminum composite panel, brushed aluminum composite panel and aluminum composite panel. Different processing methods will produce different aesthetic feelings.

Zhejiang Jinxiang Panel Industry Co., LTD. is a professional manufacturer of architectural decoration materials such as aluminum composite panel, color coated aluminum coil and aluminum ceiling. The main products are the aluminum composite panel and color coated aluminum coil. Our products passed iso9001:2000 quality certification in 2002. Established in Jinhua City, it has superior in transportation. Jinxiang aluminum composite panel is now exported to the United States, Australia, Russia, Ukraine, Azerbaijan, Kazakhstan, Turkey, Iran, Kuwait, Israel, the United Arab Emirates and other Middle East countries and Southeast Asia and other countries and regions.

ZHEJIANG JINXIANG PANEL INDUSTRY CO.,LTD. is one of the leading aluminium composite suppliersin China

Send product request

Other supplier products

| Nano Aluminum Composite Panel | Nano aluminum composite panelis a new high-end functional product springing up in the recent years. A semiconductor oxide nanometer coating (curren... | |

| Aluminum Composite Panel | We have aluminium composite panels for sale! The aluminum plastic plate also called pe aluminum composite panelas a new type of decorative materia... | |

| Antibacterial Aluminum Composite Panel | Aluminum composite panel decorative material is easy to attach to the surface of coating because of moisture and oil content from air, bacteria fro... | |

| Outdoor Aluminum Composite Panel Installation | Aluminum composite panel installation attentions:1. The variety, quality, color, pattern and line of the aluminum composite panel should meet the... | |

| ACP Interiors | The thickness of aluminum composite panel interiors The thickness of the upper panel is 0.20mm, its smallest thickness is at least 0.10mm, its tot... |

Same products

| Antimicrobial Lacquered Aluminum Foil for Insulation | Seller: HIGH TECH VIP | Anti-microbial lacquered aluminum foilis specially developed for some buildings with high air qua... | |

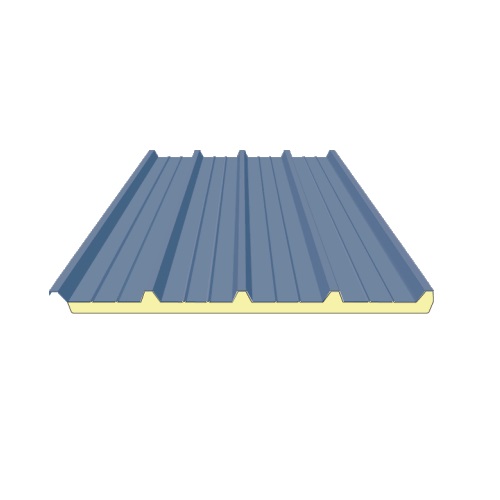

| PUR PIR Sandwich Panel | Seller: HIGH TECH VIP | PUR PIRSandwich boardsfor the construction industry are divided into a variety of insulating mate... | |

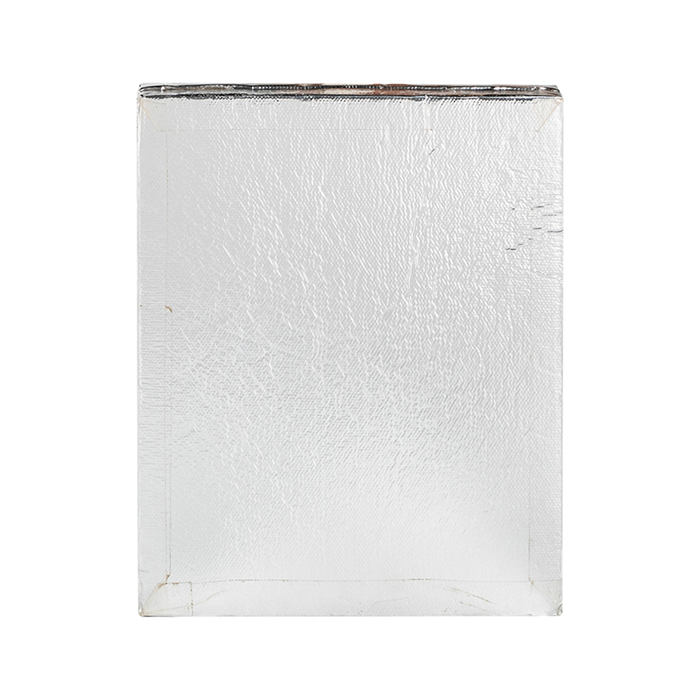

| Fumed Silica Vacuum Insulation Panels (VIP) | Seller: HIGH TECH VIP | Fumed Silica Vacuum Insulation Panels (VIP)are high-performance thermal insulation materials prim... | |

| Epoxy Coated Aluminium Coil Supplier | Seller: LITONG ALUMINUM INDUSTRY (Wuxi) CO., LTD. | Epoxy Coated Aluminium Coil Supplier Epoxy coated Aluminium Coil is an aluminum substrate u... | |

| embossed aluminium coil | Seller: LITONG ALUMINUM INDUSTRY (Wuxi) CO., LTD. | embossed aluminium coil Embossed Aluminum Coil is an aluminum sheet or coil with a pattern ... |