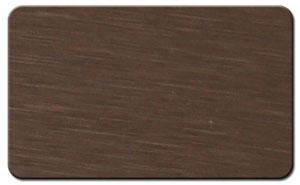

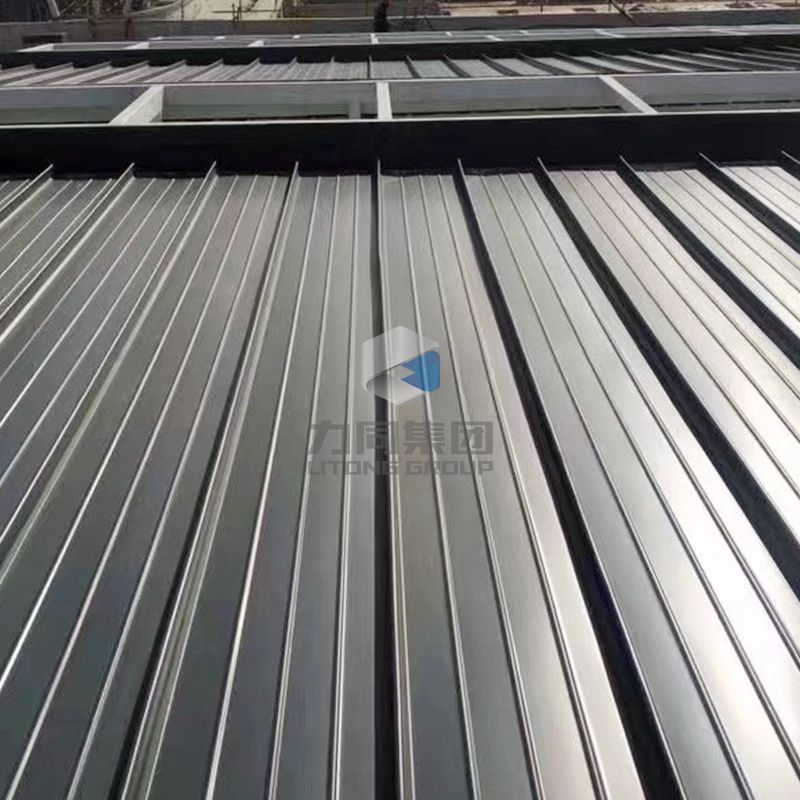

Brushed Aluminium Composite Panel

The processing craft of brushed aluminium composite panelis a kind of manufacturing process that repeatedly uses sandpaper to scrape out wires on the surface of the aluminum composite panel. The process is mainly divided into three parts: degrease, the sand mill and water scrubbing. In the wire drawing process of the aluminum composite panel, after the anode processing, the special skin membrane technology will generate an epithelial layer, which contains metal, on the surface of the aluminum composite panel, making each tiny wire is clearly visible, thus showing gloss on the matte metallic. Nowadays more and more aluminum composite panel products have adopted wire drawing craft on the surface of the aluminum panel to make it beautiful and corrosion resistant. Making products both fashionable and technological is one of the reasons why the technology is so popular.

The wire drawing of the brushed aluminium composite sheetcan be divided into straight lines and shredded strands. There are other kinds of drawing effects, such as weaving, folding and so on.

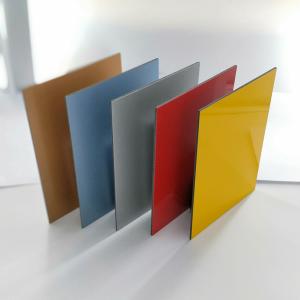

The colors of the brushed aluminum composite panel include: JK001 bronze, JK002 green, JK004 blue, JK003 stainless steel color, JK005 red, JK006 silver, JK007 gold, JK008 purple bronze, JK009 black, JK010 pink, JK011 brassy, JK012 bronze color, JK026 Tieshuyinhua, JK036 inferior smooth color and so on.

The following problems are easy to appear in the process of aluminum composite panel drawing. But our company has corresponding effective methods to solve the following problems, thus ensuring the quality and aesthetics of the products:

This problem can be caused by many factors. The size discrepancy of aluminum panel material, the inconsistent wear degree of drawing wheel caused by wire drawing positioning, and the uneven wire depth and density on the edge of the panel when processing different sizes panel, these three factors are relatively common. The solution to solve these problems is that: before processing the different batch of the aluminum panel, maintain the wheels and prepare a group of spare wheels as a replacement. In the production, after 100-120 panels are produced, the wheels should be replaced by the spare wheels to avoid the inconsistent wear degree of the wheels.

The most probable cause is that the wire drawing equipment is not well controlled, resulting in a shallowness of the lines drawn out. Moreover, the clarity of brushed aluminum composite panel is reduced again after the oxidation corrosion.

The low concentration of tank liquor in the production line and the extremely high temperature will cause surface dusting. This problem is a human factor. The problem will occur when the production workers don't monitor the concentration of the bath liquid correctly so that causing the temperature and concentration deviates from the standard.

In addition, Jinxiang aluminum composite panel has the following advantages:

The brushed aluminum composite panel has been through high-quality wire drawing process so that do not need long-term care, helping to save the cost of large buildings ACP maintenance. Because of the air pollution, the aluminum composite panel needs to be clean every several years. But the cleaning is also easy so that will not cost much. You can just clean them by using water and neutral detergent.

The aluminum composite panel has the advantages of durability, weather resistance, high-temperature resistance, abrasion resistance and pollution resistance.

The aluminum composite panel features excellent flat surface, which satisfies the pursuit of high perception of modern architecture.

The aluminum composite panel is made of aluminum alloy and high-quality plastic. The weight is lighter than other decorative materials, reducing the weight of the material itself and making it convenient for construction and greatly shortening the construction period.

The aluminum composite panel is easy to cut, gouge, bend into the arc, right Angle, and other shapes and can be designed into various shapes to meet the demand of decoration.

The incombustible aluminum panel can protect the PE core material and prevent the heat conduction at the beginning of combustion. Its performance in fire resistance has met the international standards.

The aluminum composite panel can be made with special colors and shapes according to the requirements of customers and satisfy the designers’ original design, achieving the perfect decoration.

The surface layer does not change and produces no pollution to the environment.

Construction technology:

First, setting-out work. The setting-out work is carried out according to the actual Central Line and elevation point of the civil construction; The design of the veneer is based on the axis of the building. The skeleton of the aluminum plastic plate is composed of horizontal and vertical parts. The position line of the vertical bar is first played, then the anchorage point of the vertical bar is determined.

Second, install the fixed connectors. On the base of the line, fix the connecting parts with electric welding, and the weld shall be anti-corrosive. The connecting piece is welded and fixed with the embedded parts in the main structure. When the main structure is not embedded with iron parts, the expansion bolts can be set in the main structure and fixed with the connection iron.

Third, install skeleton. To install the skeleton with the welding method. Check the installation elevation, centerline position, and do anti-rust paint processing at the cross-section of the weld at the same time. Hidden test records should be done for the fixed fittings including fittings weld embedment length, thickness and position level, quantity, embedded depth.

Forth, the aluminum composite panel is installed on the internal frame of the profile. First, drill the milling screw at the right position, and fix the aluminum composite panel veneer on the steel frame with rivets. The gap between plates should be 10 ~ 15mm. And then inject silicone weathering sealant. Before the aluminum plate is installed, it is forbidden to remove the wrapping paper until it is finished. The construction should be operated according to the arrow direction marked on the aluminum composite panel.

Send product request

Other supplier products

| Marble Aluminum Composite Panel | The marble aluminum composite panel surface is decorated and protected by the high-quality resin emulsion paint offered by reliable suppliers. It h... | |

| Antibacterial Aluminum Composite Panel | Aluminum composite panel decorative material is easy to attach to the surface of coating because of moisture and oil content from air, bacteria fro... | |

| High Gloss Aluminum Composite Panel | High Gloss Aluminum Composite Panel White aluminium composite panelor aluminum-plastic panel is a kind of composite new material which has been t... | |

| PVDF Aluminum Composite Panel | PVDF Aluminum Composite Panel The aluminum composite panel is a new type of material that has been surface-treated and coated with an aluminum pl... | |

| PE Aluminum Composite Panel | PE Aluminum Composite Panel PE aluminum composite panelis generally used for interior wall decoration.Polyester paint (PE): >0.016mm measured ... |

Same products

| Antimicrobial Lacquered Aluminum Foil for Insulation | Seller: HIGH TECH VIP | Anti-microbial lacquered aluminum foilis specially developed for some buildings with high air qua... | |

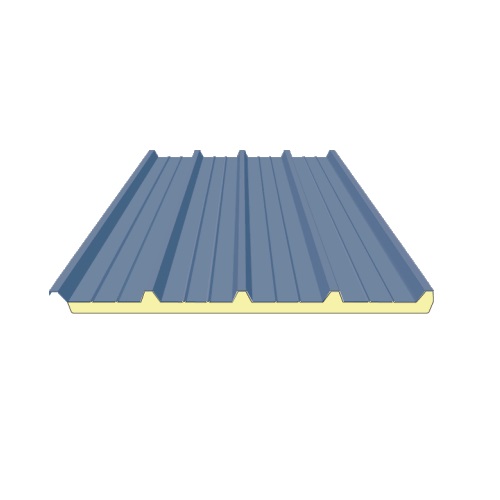

| PUR PIR Sandwich Panel | Seller: HIGH TECH VIP | PUR PIRSandwich boardsfor the construction industry are divided into a variety of insulating mate... | |

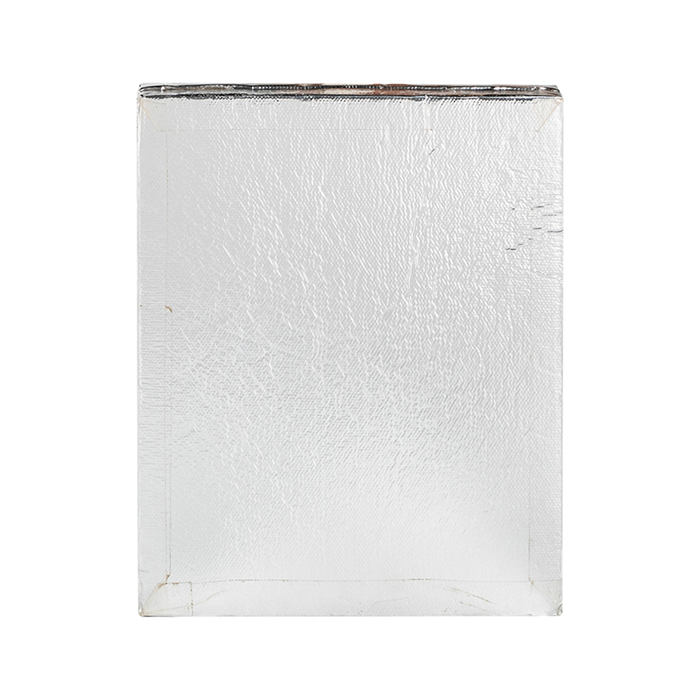

| Fumed Silica Vacuum Insulation Panels (VIP) | Seller: HIGH TECH VIP | Fumed Silica Vacuum Insulation Panels (VIP)are high-performance thermal insulation materials prim... | |

| Epoxy Coated Aluminium Coil Supplier | Seller: LITONG ALUMINUM INDUSTRY (Wuxi) CO., LTD. | Epoxy Coated Aluminium Coil Supplier Epoxy coated Aluminium Coil is an aluminum substrate u... | |

| embossed aluminium coil | Seller: LITONG ALUMINUM INDUSTRY (Wuxi) CO., LTD. | embossed aluminium coil Embossed Aluminum Coil is an aluminum sheet or coil with a pattern ... |