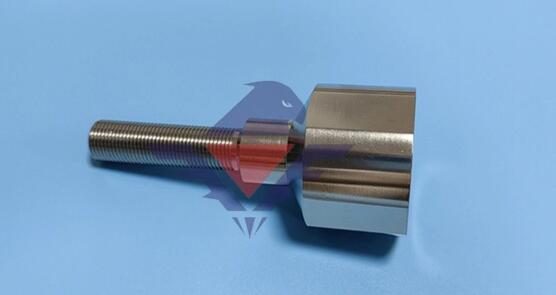

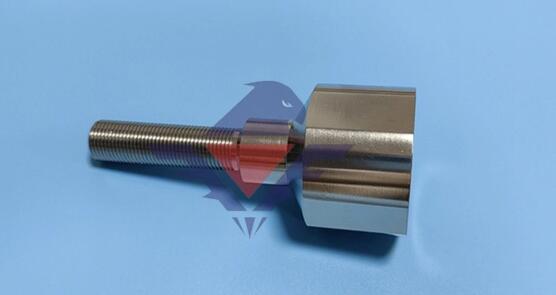

CNC Swiss Machining

Swiss machining is a specialized type of precision machining that involves the use of a sliding headstock lathe to produce intricate parts with high accuracy and tight tolerances. This process is particularly well-suited for small, complex parts that require multiple operations to be performed in a single pass. Swiss machining is known for its ability to produce parts with very tight tolerances, high surface finishes, and excellent straightness, roundness, and concentricity. Falcon's Swiss machining technology is widely used in industries such as medical, automotive, aerospace, optics, and electronics, machine & equipment, where precision and quality are of utmost importance.

What Are the Advantages of cnc swiss precision machining?

High precision and accuracy: Swiss machining equipment uses advanced technology and specialized tools that allow for very tight tolerances, resulting in parts with exceptional precision and accuracy.

Consistency and repeatability: Highly automated lathe, ensuring consistency and repeatability in the manufacturing process, which is critical for high quantities production.

Multi-axis machining: The Swiss lathe has multiple axes that allow for complex geometries and shapes, which is essential for producing intricate parts and components.

Reduced lead time: Swiss machining is known for its high efficiency and fast production times, resulting in reduced lead times and faster delivery of parts and components.

Versatility: It can work with a wide range of materials, including metals, plastics, and composites, making it ideal for various industries such as aerospace, medical, and automotive.

Cost-effective: Swiss machining is a cost-effective solution for high-volume production runs, as the high level of automation reduces labor costs and minimizes waste.

Why Is It Called Swiss Machine?

The term "Swiss machine" typically refers to a type of precision lathe called a Swiss-type lathe, also known as a Swiss screw machine. This type of lathe was originally developed in Switzerland in the late 19th century for the watchmaking industry, which required very precise and complex parts to be produced in large quantities.

Over time, the use of Swiss-type lathes has expanded beyond the watchmaking industry to many other industries that require high-precision parts, such as medical, automotive, aerospace, optics, and electronics, machine & equipment.

What Makes a Swiss Lathe Different?

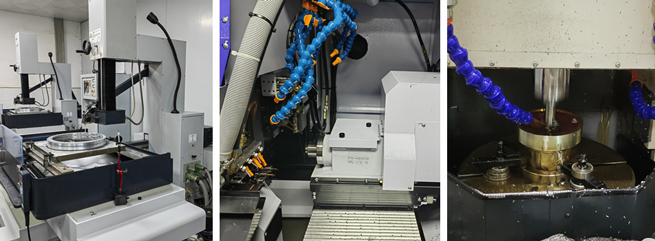

One of the key features of a Swiss lathe is its sliding headstock. This allows the material being machined to be held stationary while the cutting tool moves in and out to make precise cuts. This design reduces vibration and enables very high accuracy and precision in the machining process. Another feature that sets Swiss lathes apart is their ability to perform simultaneous multi-axis machining. This means that the lathe can perform multiple cutting operations at once, using a variety of tools, to create complex parts with multiple features.

5 Tips To Know About Falcon Swiss Machining Capabilities

1. High Volume Swiss Screw Machining Capabilities

In the Falcon workshop, we have more than 300 equipment. Most Swiss-type lathes in Falcon are with 12 axes. Their unique cutting, drilling, and production cycle time optimization capabilities are commendable. They can produce precision parts with complex geometries in a single operation, with tolerances as precise as 0.0002 to 0.0005 inches.

2. Certificate & Quality

ISO9001, ISO16949, ISO13485certified, PPAP, and FMEA for automotive and medical clients.

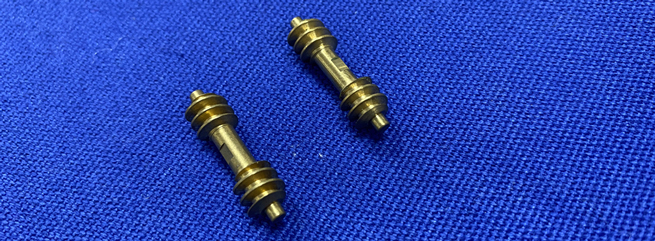

3. Micromachining for Miniature Machined Parts

Falcon Swiss Machine Shop possesses the core technology for manufacturing micro precision parts, including micro turning, micro drilling, and precision WEDM, which can meet the stringent requirements of global customers for micro parts manufacturing.

4. Custom Precision Swiss Turned Parts

Falcon has mastered at least 475 material processing methods, 28 CNC techniques, and 30 kinds of surface treatments. Turn your papers into parts in a quick turn.

5. R&D Support

At Falcon, you can enjoy one-stop service from prototype to high-volume production. First-class Swiss lathe combined with auxiliary facilities such as automatic feeders and robots, we can produce 1,000,000 precision Swiss turning parts for you within one month.

7 Design Tips for CNC Swiss Machining

Design tips for cnc swiss turning are important for ensuring that parts are machined accurately, efficiently, and cost-effectively, while also meeting the required performance specifications. Swiss machining is quite different from other traditional machining way, Falcon engineers have summarized at least 7 points of advice to help you accurately design Swiss machined parts. Here are some design tips for CNC Swiss machining:

1. Minimize part length: Swiss-type machining is best suited for producing long and slender parts. If possible, try to design parts with a long aspect ratio, as this will help to improve the accuracy of the machining process.

2. Avoid sharp edges: Sharp edges can be difficult to machine accurately and can also cause tool breakage. Try to design parts with rounded edges and contours, as this will help to reduce stress on the cutting tool.

3. Optimize material usage: Swiss-type machining can be expensive, so it's important to optimize material usage as much as possible. Try to minimize the amount of material that needs to be removed during the machining process by designing parts with the proper dimensions and tolerances.

4. Minimize part complexity: While Swiss-type machining is capable of producing complex parts, it's generally better to minimize part complexity wherever possible. Simple, straightforward designs are easier to machine accurately and quickly.

5. Consider tool access: Swiss-type machines have limited tool access due to the guide bushing that supports the workpiece. Make sure to design parts with tool access in mind, and avoid designs that require tools to be inserted at awkward angles.

6. Use appropriate materials: Swiss-type machining is best suited for producing parts from materials such as stainless steel, titanium, and other high-performance alloys. Make sure to choose materials that are appropriate for the application and machining process.

7. Design for efficient production: Finally, it's important to design parts with efficient production in mind. Try to minimize the number of operations required to produce each part, and consider using common tooling and fixturing to reduce setup time.

Other supplier products

|

|

Brass and Copper Precision Machining Services |

Brass and Copper MachiningServices

Is Brass Easier to Machine than Copper?

Copper is a soft, malleable metal that is an excellent conductor of ... |

|

|

Precision Aluminum Parts |

Aluminum is a popular material for Swiss machining due to its excellent strength-to-weight ratio, corrosion resistance, and versatility. At Falcon,... |

|

|

CNC Swiss Machining |

Swiss machining is a specialized type of precision machining that involves the use of a sliding headstock lathe to produce intricate parts with hig... |

|

|

Automotive Precision Machining |

Automotive Precision Machining CNC machining technologies are widely used in the automotive industry to manufacture high-quality automotive parts t... |

|

|

Precision Mmedical Swiss Machining |

Precision Medical Swiss Machining

Medical manufacturing refers to the production and distribution of cnc machining medical devices, equipment, and... |

All supplier products

Same products