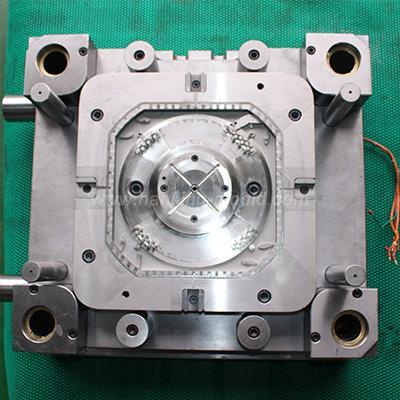

3 Plate Mould 49113-21.

Mould Name: 3 Plate Insert Mould/ 3 plate injection mold

Part Material: PBT GF15

Product Size: ф34.9x82.29

Product Description: Mischschraube kpl

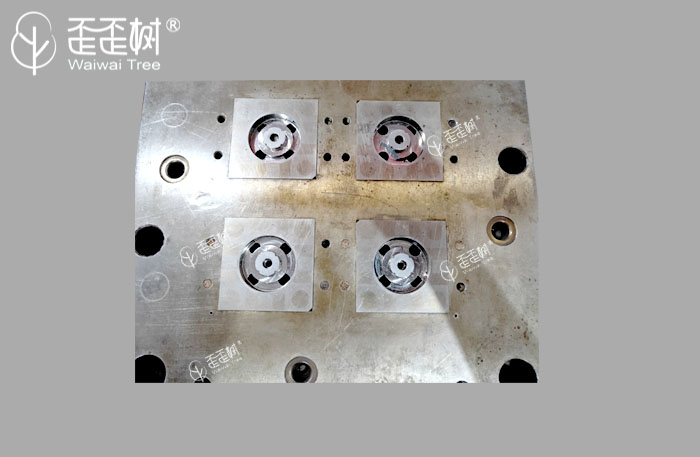

Mould Cavity: 2 Cavities

Mould Size: 250*230*350 MM

Mould Cavity Steel: 2343 ESR

Mould Injection System: 3-Plate point gate

Mould Ejection System: Round ejector

Mould Cycle Time: 28's

Mould Life Cycle: 500,000

Lead Time: 45 working days

Mould Features: insert molding

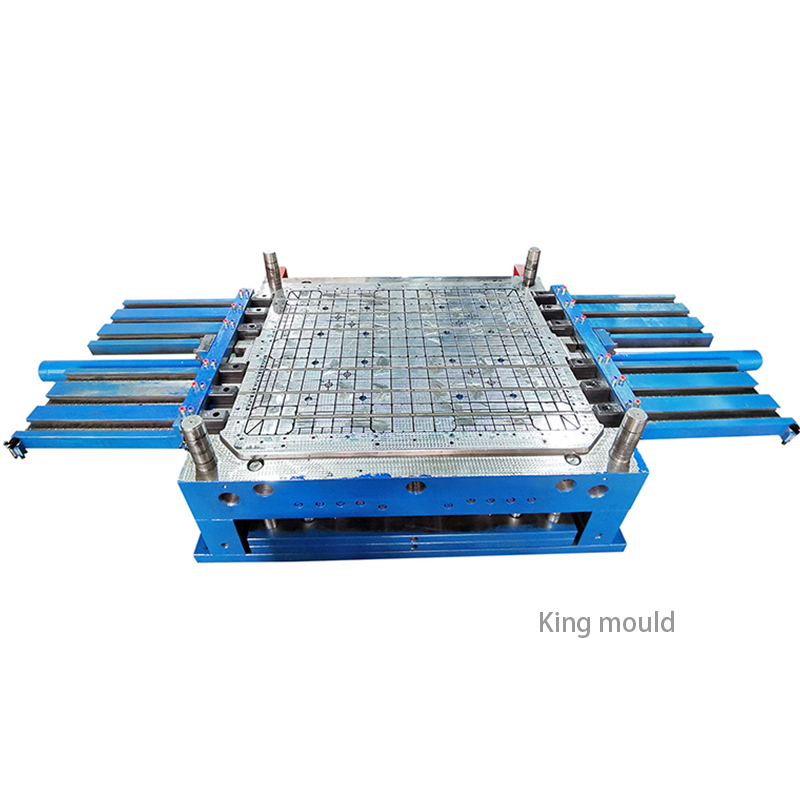

3 plate mould is also called pinpoint gate mould.

There are two parting surfaces to divide the mold into three parts. Compared with the two plate molds, the gate plate of three plate mold is added. It is suitable for the molds that do not allow gate marks around the product. This type of mold uses a pointed gate, so it is called pinpoint gate mold.

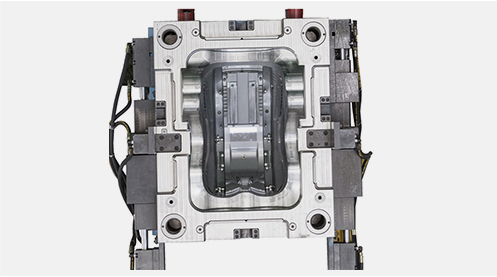

The typical 3 plate mould movement process

The three plate mould workingprocess: the three-plate mold has two parting processes, the first between the stripping plate and the cavity plate, and the second time between the cavity plate and the core plate. When the core side is pulled by the injection molding machine, as the A and B plate are equipped with a latch lock, and there is no connection or obstruction between the stripping plate and the A plate (in most cases, the pull rod is also equipped with a spring) At this time, the stripping plate is first separated from the cavity plate by the pulling force, and the cavity plate moves backward with the core plate. When moving to the set distance, it is blocked by the pull rod limiting block, because the A plate continues to move with the injection molding machine. Therefore, the pull rod is also driven, and the pull rod drives the stripping plate to move to the next set distance and then the pull rod and the cavity plate stops moving.

The injection molding machine continues to move backward, as the pulling force continues to increase, exceeding the locking force of the latch lock, the A plate is separated from the B plate, and stops when the set distance is reached.

The ejector plate drives the ejector mechanism (the ejector pin, the ejector rod, and the lifter) to start the ejection movement, and the finished product is ejected (automatically dropped or removed by the robot).

Clamping process - When there is a pullback mechanism on the ejector plate, the ejector plate is forcibly pulled back by the injection molding machine before clamping.

Under the push of the injection molding machine, the core moves forward to the cavity side, if the ejector plate is not pulled back in advance, the return pin first contacts the cavity plate. Under the reaction force, the ejector plate is returned by the return pin.

The B plate is pressed against the A plate and the stripping plate, and finally completely tight. The nozzle on the injection molding machine is closely fitted with the nozzle bushing on the mold, and the next cycle of injection molding is started.

About Hanking Mould

HanKing Mould Enginering Ltd. started the business in the year of 1996 as a injection molded parts china. With continuous developments and progresses, we have become a professional Chinese plastic injection tooling company, offering custom plasticmoldingservice, plastic molding manufacturing and other mould making services.

Send product request

Other supplier products

| Automotive Molding Parts | Injection Molding Automotive Parts Hanking mouldinvolves various automotive injection plastic mold oem, our engineers are familiar with the charac... | |

| Industrial Mould | Industrial mouldsis not a mold technology process, but a type of mold that is distinguished from the purpose of use. Generally speaking, products... | |

| Medical Molding Parts | HanKing has an experienced team focusing on making injection moulds and molded components for injection parts medical, medical instruments, medical... | |

| Automotive Molding Parts | Car plastic mold mexico Car plastic mold mexico HanKing is specialized in high precision plasitc injectionmoulds and molding service of automotive ... | |

| Double Injection Mold Parts | Double Injection Mold Parts Part function: Plastic Lid for coffee machine Part Standard according to ISO 11496 Surface: SPI A-2 finish Flammabil... |

Same products

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |