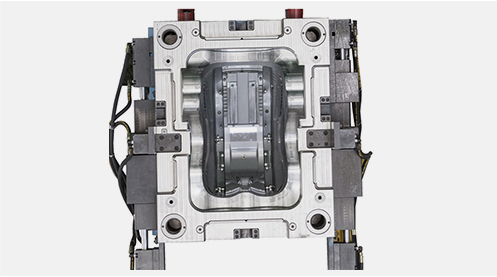

Over-Molding Parts

The plastic injection overmoldingpart is a process that can bond different materials by the injection molding.

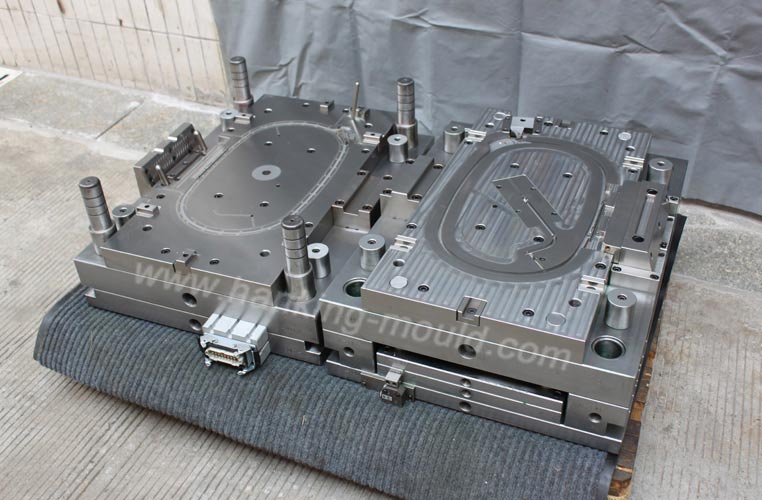

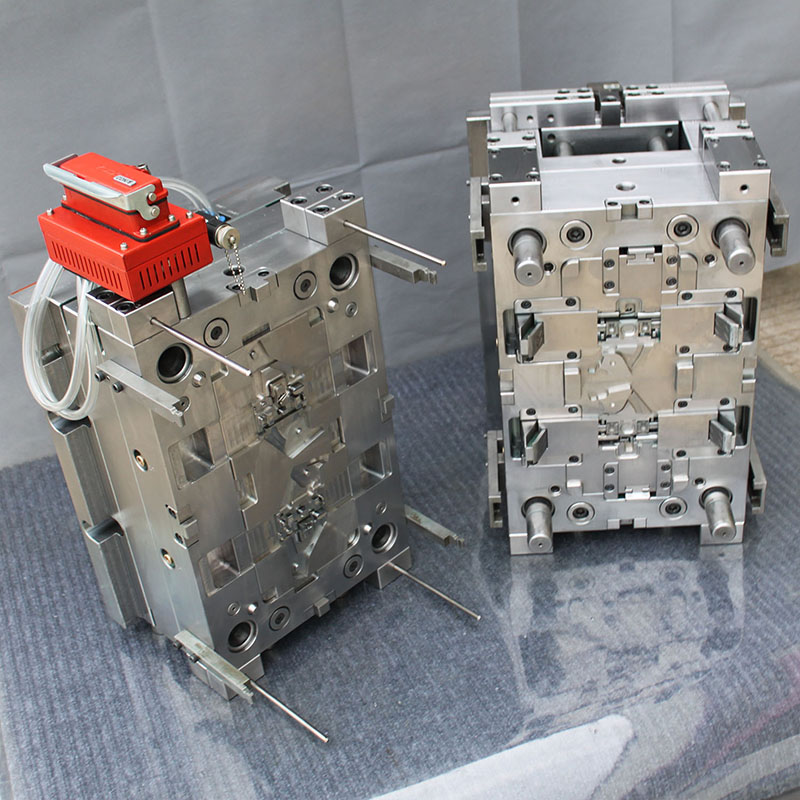

Over-molding in HanKing is a technology to combine two different moulds while we called the combination of different resins in one mould as two-shot. Knowledge of plastic resin compatibility is very crucial for over-molding, HanKing's expertise assure the performance of the over-molding part is bonded strong.

There are many factors in the selection of over-molding resins, it depends on the properties of the basic resin and on the other hand on the application properties. Specifically, there are the following:

- Corrosion resistance.

- Flame retardant (in line with ecological and environmental requirements). The eco-friendly logo is a sign that the product meets environmental and social standards.

In general, the matching material should have similar chemical properties or contain matching composite elements. When the basic resin does not match the covering material, it usually only forms a mechanical interlocking effect, not a chemical bonding.

Soft plastic resin can be molded with different materials, but it is more limiter and stricter when hard plastic is over-molded with other hard resin.

It is acceptable to overmolded partswith two hard resins in small areas, but it cannot be used in large areas and designed the second hard plastic over-molded the first hard resin as a closed ring.

From design work as mould base selection, wall thickness, filling balance, ejector balance, even venting to subsequent manufacturing process, HanKing will consider all the details in order to make a custom mold & designthat will satisfy the customer.

Hanking Mould Engineering Ltd. is a professional chinese injection molding companies(overmolding companies), we provide hanking mold, industrial molds, insert moulding products and etc. Want to know more? Please contact us.

Send product request

Other supplier products

| Plastic Injection Moulds | HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold... | |

| Precision Mould | Injection Plastic Mold Injection plastic mold is another name for plastic injection mold. This is just how people in various places call injection... | |

| Plastic Precision Car Parts | Mould Type: Plastic Precision Car PartsMould Production Material: PC, PP, PA6, PA66, PE, ABS, HDPE, TPE, TPU, PET, PPS, POM, PBT, PMMA, PPS, SAN... | |

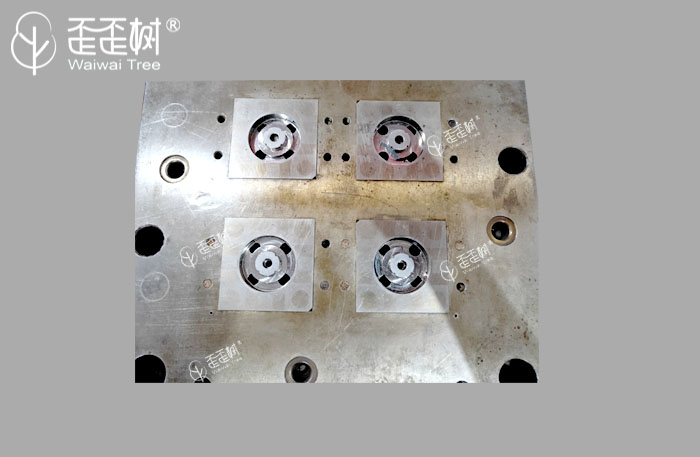

| Consumer Parts Plastic Mold | Consumer PartsPlastic Mold Description: Plastic Valve 3 Plate Mould Tolerance: +-0.01mm Surface: SPI A2 & VDI 3400 Part material: PPO food gra... | |

| Automotive Molding Parts | Injection Molding Automotive Parts Hanking mouldinvolves various automotive injection plastic mold oem, our engineers are familiar with the charac... |

Same products

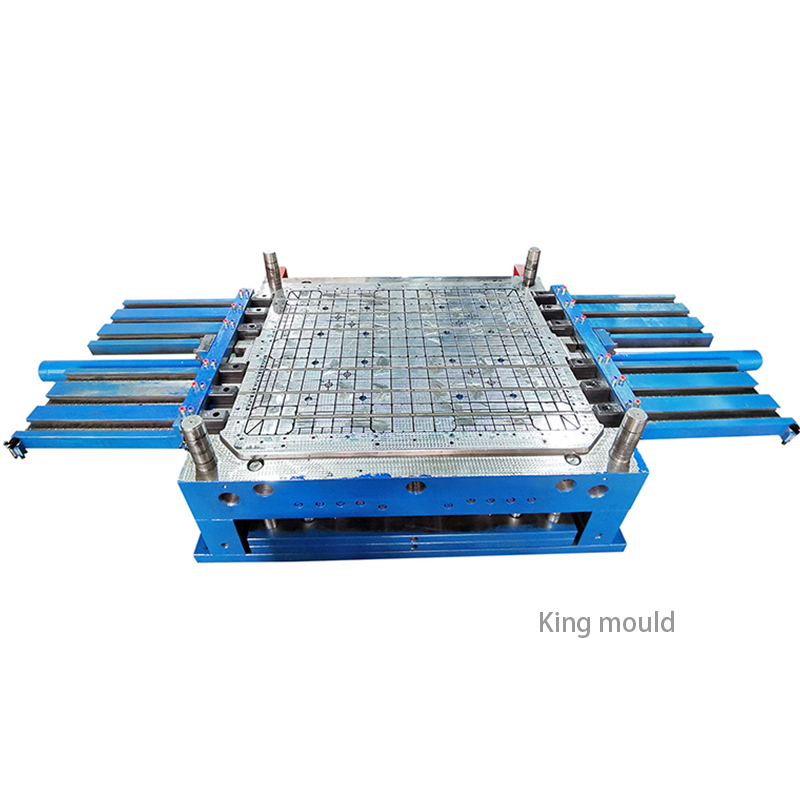

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |