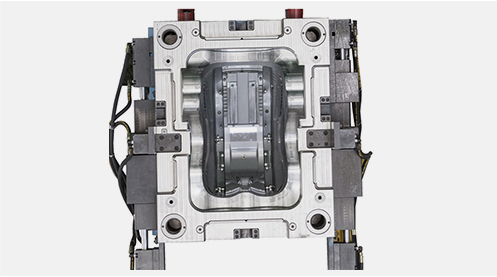

What is a BMC Mould? What Are the Features and Applications?

BMC is the abbreviation of Bulk Molding Compounds. It is also cluster moulding plastics.

What is a BMCmould? What are the features and applications?

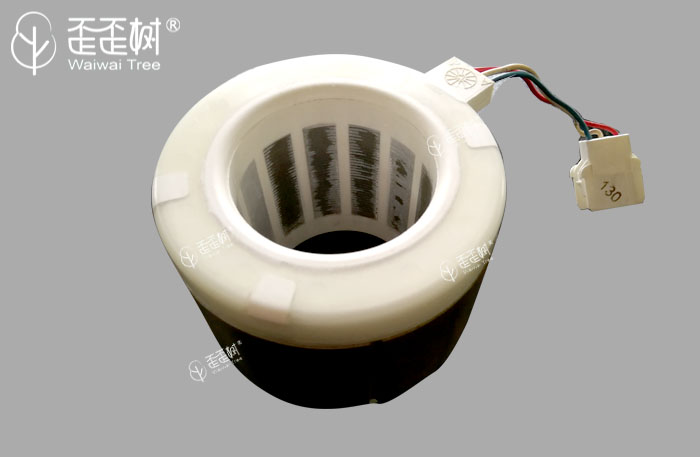

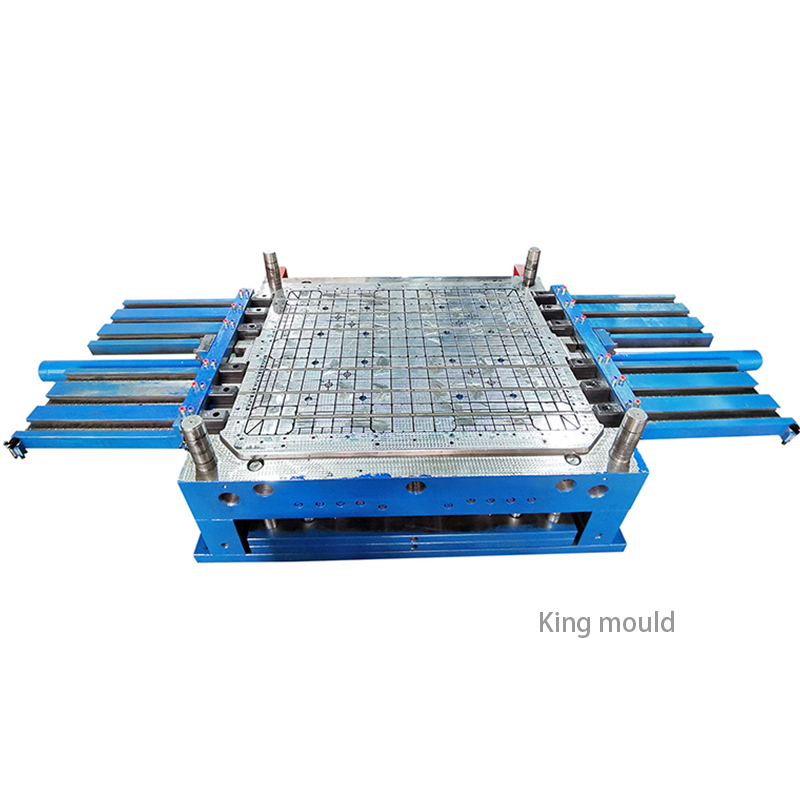

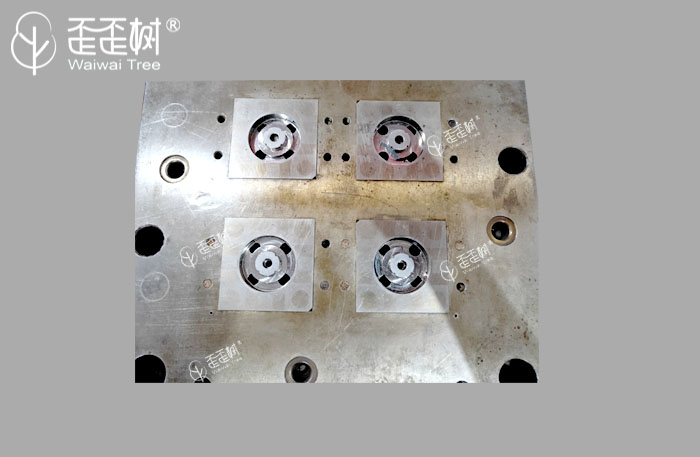

BMC compositeis a kind of thermosetting plastic, which mixes various inert fillers, fiber reinforced materials, catalysts, stabilizers and pigments to form a kind of adhesive "putty" composite material for compression or injection moulding. It is usually made into grains, logs or strips by extrusion method in order to facilitate subsequent processing and moulding.

BMC has many unique characteristics, such as high hardness, light weight, corrosion resistance, ultraviolet resistance, good insulation, excellent thermal characteristics. These make BMC more satisfying than thermoplastics. At the same time, because many components can be moulded at the same time with these components, there is no need for post-processing, so it is more economical from the production point of view.

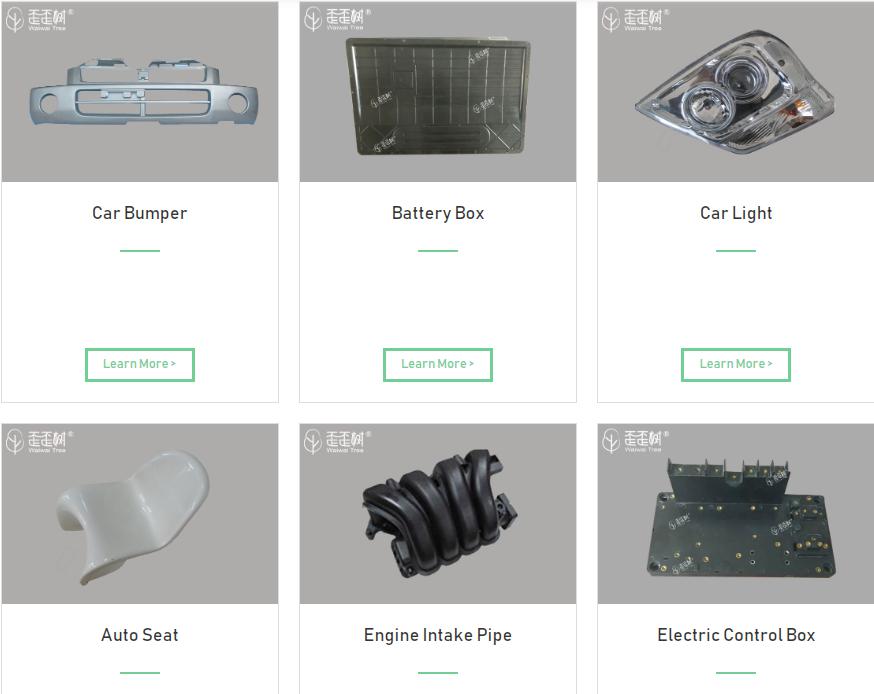

At present, BMC products have been used in automotive, energy, electrical appliances, catering services, household appliances, optical instrument components, industrial and building supplies and other areas.

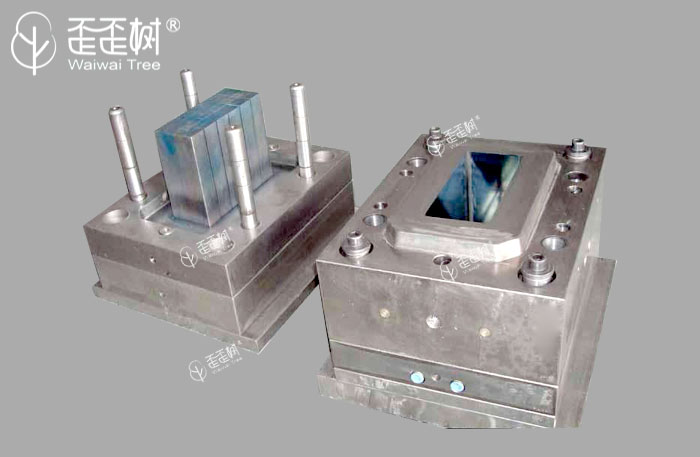

Zhejiang Aobang Technology Co., Ltd. has developed many BMC die products, such as taillight hood, electrical box, watt-hour meter box, new energy battery cover, automobile bumper die, die for automobile wing plate, guide hood die and so on.

More details of bulk molding compound process, please leave us a message.

Send product request

Other supplier products

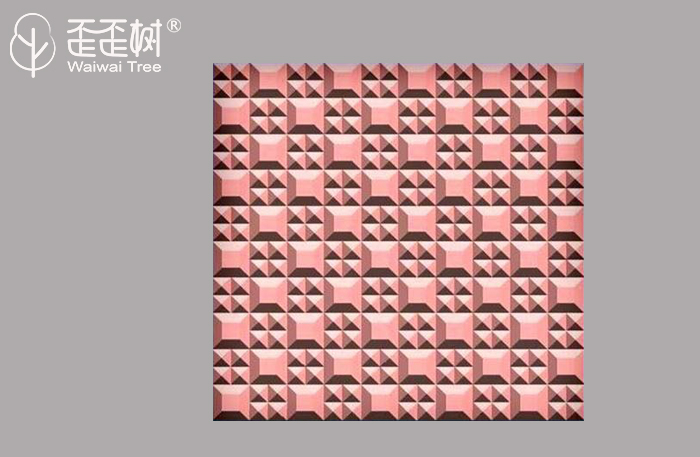

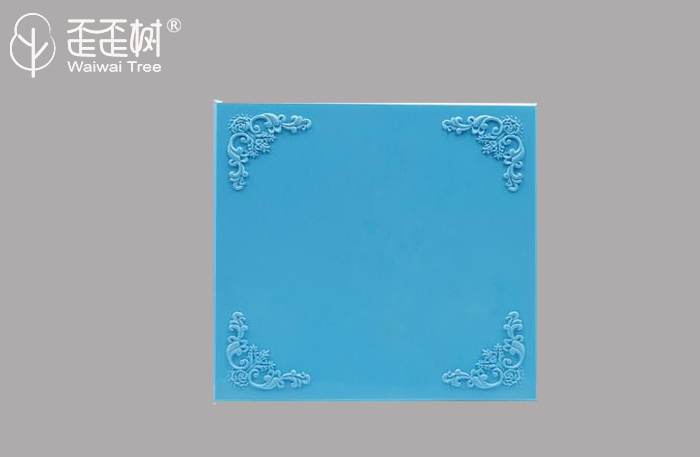

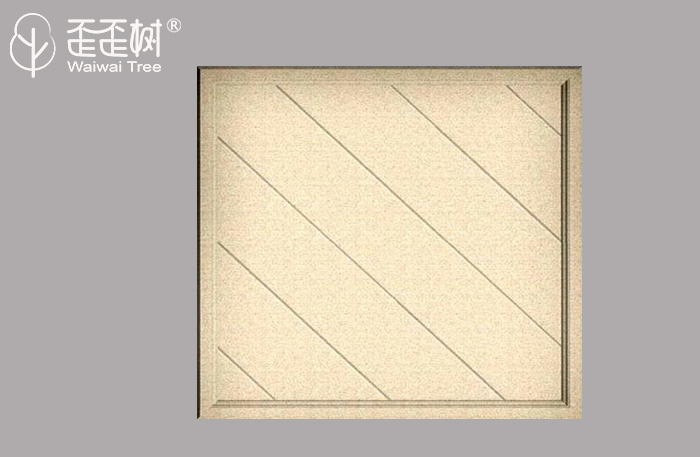

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| Auto Parts Mould | BMC Car PartsMould Automobiles are different in size and shape. That means automobile suppliers always need flexible auto parts molds, once there ... | |

| BMC, SMC, GRP, GFK Roof Tiles | What Is GFK Material BMC, SMC, GFK, GRP roofing materialsare glassfiber reinforced plastic, also known as glassfiber roof, which are composed of r... | |

| Auto Parts And Accessories | Auto Parts Description Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same... | |

| BMC, SMC, GRP, GFK Wall Panel | BMCcompositewall panel is a new generation of high performance building partition board made of a variety of building materials instead of traditio... |

Same products

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |