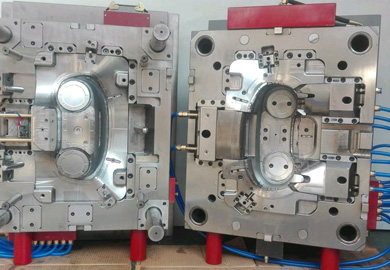

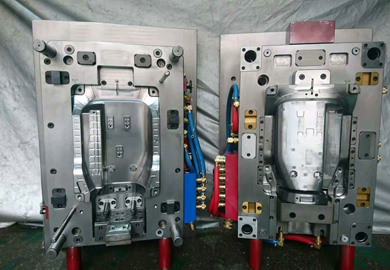

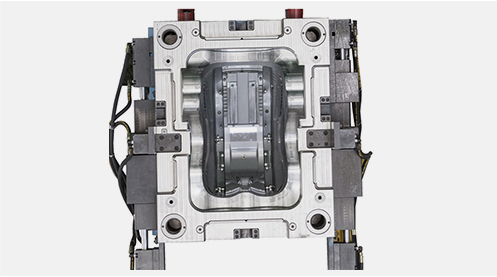

Automotive Part

Automotive Part

As the foundation of the automotive industry, injection moulding automotive partsare necessary factors to support the sustainable and healthy development of automotive mold manufacturers.

In particular, the current independent development and innovation in the automotive parts mold industry that is being carried out vigorously and in full swing require a strong component system in automotive plastic injection molding companies. Vehicle independent brands and technological innovation require automotive injection mold parts and components as the foundation, and independent innovation of parts and components has a strong driving force for the development of the vehicle injection molding automotive parts moldindustry.

Features of Automotive Injection Mold

Here are three major features of usingautomotive injection moldingfor manufacturing injection moulding car parts.

Detailed Features

The automotive plastic injection molding is subjected to extremely high pressure. Therefore, the plastic is pressed harder against the automotive parts mold. This complex and intricate shapes of plastic injection molding automotive parts can easily be designed.

High Efficiency

Once the automotive parts molds have been manufactured to the customer’s specifications, it is very quick to the actual automotiveprecision custom plastic injection moulding. The high production output rate makes plastic injection molding automotive parts more cost-effective and efficient.

Enhanced Strength

In automotive plastic injection molding, it is possible to use fillers in the injection molds. This filler reduces the density of the plastic which will enhance strength.

How does Automotive Injection Mold Work?

Automotive injection mold is to first add plastic to the mold, and then the automotive parts mold is continuously rotated along two vertical axes and heated. Under the action of gravity and thermal energy, the plastic in the automotive parts mold is uniformly coated and melted, and adhered to the entire cavity of the mold. On the surface, it is formed into the required shape of injection molding automotive parts and is made by cooling and shaping.

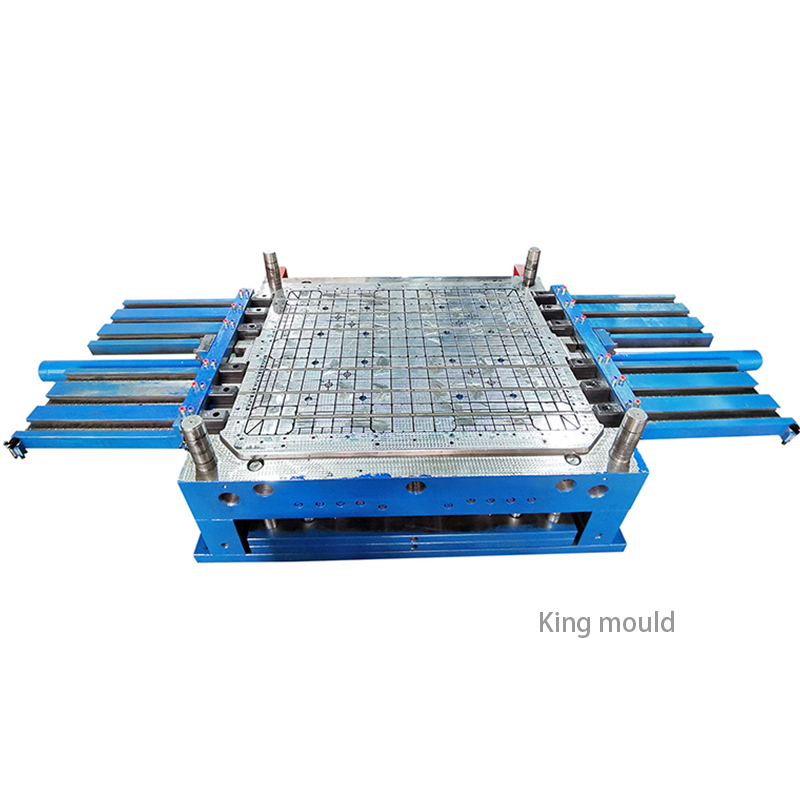

The Specification of injection molding automotive parts

|

Part material |

ABS + PC |

|

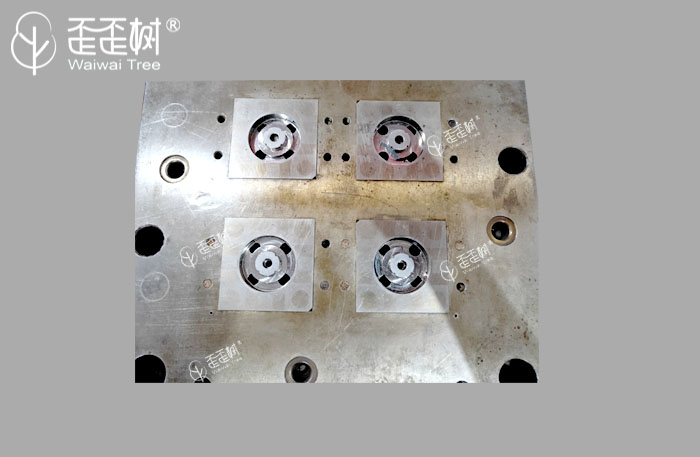

Mould Cavity |

1 |

|

Mould steel |

|

|

Mould steel |

A, B, C, plate P20, others 1.1730 |

|

Tooling life |

100W |

|

Mould standard |

HASCO |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Customer satisfaction with mould quality |

95% |

|

FAI pass rate |

99% |

|

Customer satisfaction with project cooperation service |

98% |

If you want to know more details of in mold technology, please visit our website.

Send product request

Other supplier products

| Mould Design | As an injection molding companies, GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and othe... | |

| Medical Equipment Mould | Medical products include syringes, and internal and external parts of medical equipment. Features of medical device injection molding Our company ... | |

| Mould Design | GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and other mold design standards, be able to... | |

| Insert Mould | Insert molding is an injection molding process used to encapsulate a component in a plastic part. The insert custom plastic injection moldingpro... | |

| Household&Home Appliance Mould | Household&Home Appliance Mould Home appliance moldcombines different types of molds such as gold stamping mould, plastic mould, and adsorption... |

Same products

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |