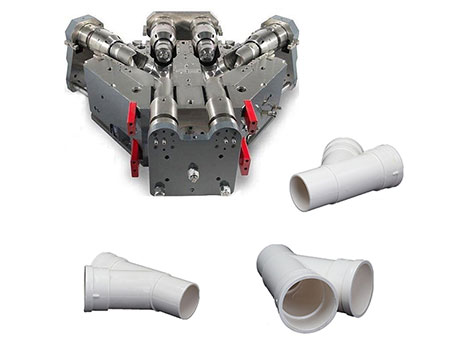

Plastic Food Container Mould

Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental protectionso, we have to choose proper plastic materials, such as food grade PP,PS,starch material,Plant fiber material etc., then food container mould should be signed with high polish, good injecting and cooling systems to make sure the boxes could be with good shap and finish.For enhancing the speed, normally we suggest to produce plastic container mouldon high speed injection machines.

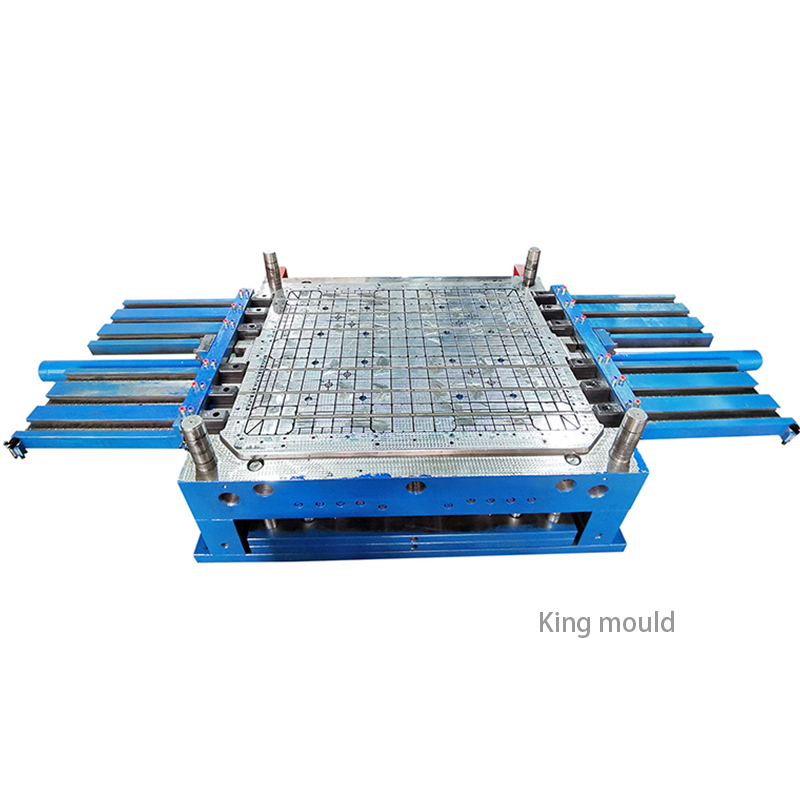

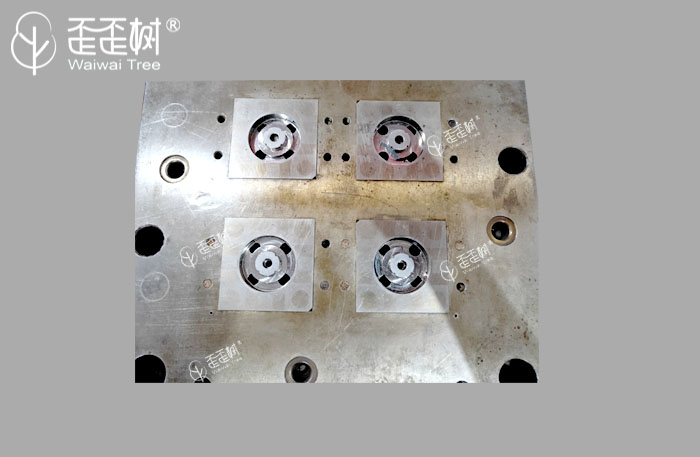

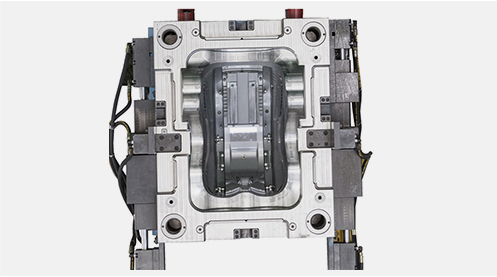

High-quality Food Container Mould

As the wall thickness of the boxes is normally very thin, it's very important to design and make high-quality plastic food container mould. An efficient mold cooling system can shorten the injection cycle and save more processing costs and time. We pay great attention to the mold cooling system and mold production stability. Our goal is to ensure customers run as little mold repair work as possible and be able to perform mass production efficiently and stably.

Making plastic food container mouldtips

Designing about 2-3 different sizes of plastic meal boxes with the same lid could save the mold and production cost.

The thickness of the boxes is thin, so we need to design the mold with a good cooling system.

The materials of the boxes should be safe for hot food and meet environmental concerns.

To enhance production efficiency, you need to use a high-speed injection molding machine for production.

Using robots to pick up the parts during production can also enhance production efficiency.

Following our construction to install and use the mold, to make sure there's no any damage for the mold and less repair.

For more information about plastic molding,please feel free to contact us!

Send product request

Other supplier products

| Industrial Plastic Injection Mold | Industrial Plastic Injection Mold The injection molding part is replacing metal products in many fields of industrial applications to meet the... | |

| Plastic Toilet Seat Mold | Toilet seat casting moldquality points: cover mold cycle, cover mold life, Parting line whether there are sharp edges? Is the cover wall thickness ... | |

| Soap Box Mold | Plastic soap is also made by plastic injection mold, as it need dimensional stability, good apperance and good color performance, so we have to cho... | |

| Teeth Tray Mold | A dental impression is a mold removed from a tooth to diagnose and treat dental conditions. They are also used in forensic science. Impressions are... | |

| Plastic Toilet Seat Mold | Toilet seat mouldquality points: cover mold cycle, cover mold life, Parting line whether there are sharp edges? Is the cover wall thickness even? H... |

Same products

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |