Advantages and Disadvantages of Hot Rolled Steel and Cold Rolled Steel

Cold Rolled Steeland Hot Rolling Advantages and Disadvantages

In general, the tensile strength, yield strength, plasticity, and toughness of hot rolled steel after overheating treatment will be improved. In addition, heat treatment can eliminate residual stress, while cold rolling may produce residual stress due to the uneven yield deformation of steel during processing, which has a great impact on stability.

Both hot rolling and cold rolling are forming processes of section steel or steel plate, which have a great influence on the structure and properties of steel.

The advantages of hot rolled steel is that it can destroy the casting structure of ingot, refine the grain of steel and eliminate the defects of microstructure so that the hot rolled steel structure is dense and the hardness of hot rolled steel is improved. This improvement is mainly reflected in the rolling direction so that the steel is no longer isotropic to some extent. The bubbles, cracks, and looseness formed during pouring can also be welded under the action of high temperature and pressure.

The first disadvantage is that after hot rolling, the non-metallic inclusions (mainly sulfide and oxide, and silicate) inside the steel are pressed into thin sheets, resulting in delamination (interlayer). Delamination makes the tensile properties of the steel along the thickness direction deteriorate greatly, and it is possible that the interlaminar tear occurs when the weld shrinks. The local strain induced by weld shrinkage is often several times of the yield point strain, which is much larger than that caused by the load.

The second disadvantage is the residual stress caused by uneven cooling. The residual stress is the internal self-equilibrium stress without external force, which exists in types of hot rolled steel sections. The larger the section size of the general section, the greater the residual stress. Although the residual stress is self-equilibrium, it has a certain influence on the performance of steel members under external force. Such as hot rolled steelhardness, deformation, stability, anti-fatigue, and other aspects that may have adverse effects.

Cold rolling refers to cold drawing, cold bending, cold drawing, and other cold processing to process steel plates or strips into various types of steel at room temperature. It has the advantages of fast forming speed, high output, and no damage to the coating. It can be made into a variety of cross-section forms to meet the needs of the use conditions; cold rolling can make the steel produce great plastic deformation, thus improving the yield point of the steel.

The first disadvantage is that although there is no hot plastic compression in the forming process, there is still residual stress in the section, which will inevitably affect the overall and local buckling characteristics of the steel.

The second is that the cold rolled section is a generally open section, which makes the free torsional stiffness of the section low. In bending, it is easy to twist, while in compression, it is easy to bend and twist, and its torsional performance is poor.

The third is that the wall thickness of cold rolled steel is small, and there is no thickening at the corner where the plate connects, so the ability to bear a local concentrated load is weak.

If you want to know more details of advantages of cold rolling and disadvantages of hot plate, please visit our website.

HUAROoffers high-quality steel product, steel raw material and other raw material. We depend on Huaruo worldwide supply chain to

introduce and export our superior products.

Send product request

Other supplier products

| Hot Rolled Steel Plate | Main Feature of prime hot rolled steel sheet Hot steel coils production is a rolling procedure that relates rolling steel at a high temperature (u... | |

| Steel for Marine Use | General description of the best stainless steel for marine use Marine also is known as the shipbuilding industry, it's one of the biggest steel pr... | |

| Steel for Marine Use | General description of stainless steel for marine applicationsin Marine Marine also is known as the shipbuilding industry, it's one of the biggest... | |

| Iron Ore | How to Identify Iron Ore Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron... | |

| Steel Making Raw Material | Description of Steel Raw Material Steel is one kind of alloy, made of iron and carbon. The carbon content is usually less than two percent and for... |

Same products

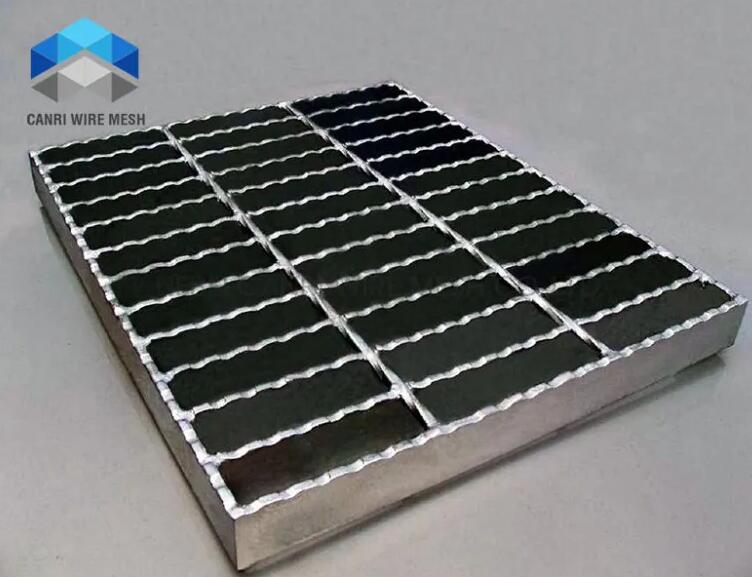

| Galvanized Steel Grating for Drainage | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

| Serrated Bar Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... | |

| Galvanized Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating Galvanized steel gratingis an ideal product for wet, slippery situation... |