ASTM A249/ASME SA249 STAINLESS STEEL TUBE

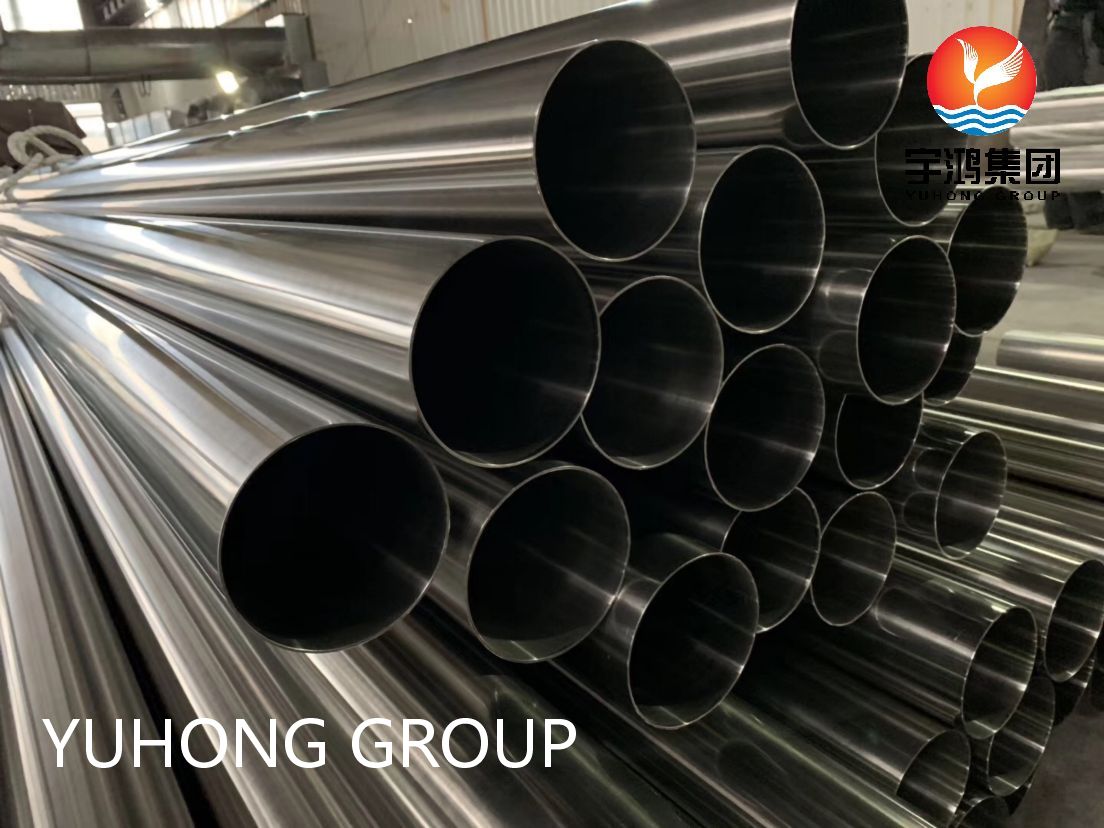

a249 stainless steel tube

astm a249 tubing/ a249 tubing

astm a249 pdf

astm a249 tp304 specification

ASTM A249stainless steel tube covers nominal wall thicknesses welded and heavily cold-worked welded pipes made of the following materials

Various grades of austenitic steel for boilers, superheaters, heat exchangers, or condenser pipes.

ASTM A249/ASME SA249 STAINLESS STEEL TUBE PROVIDED BY YUHONG

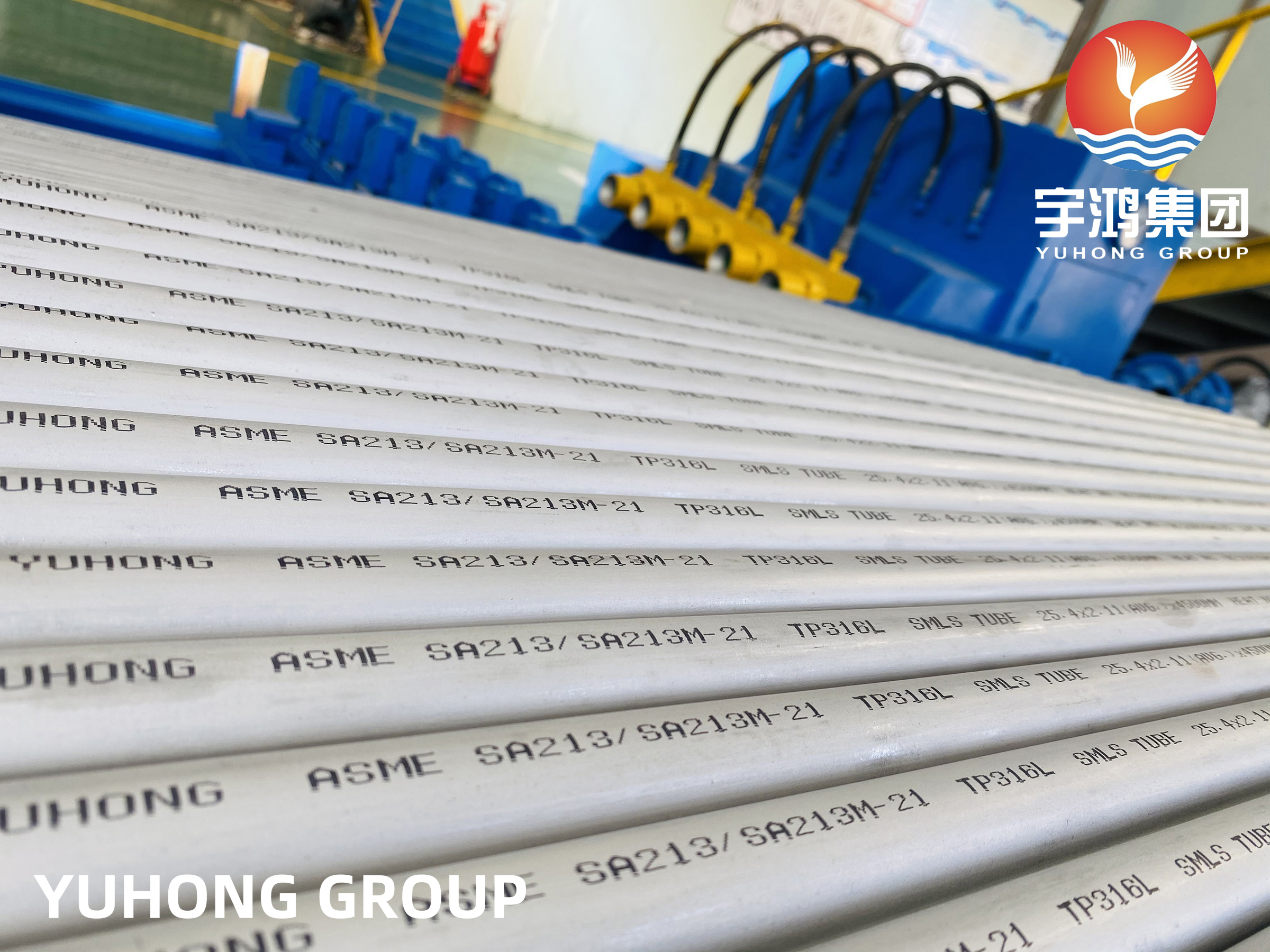

ASME SA249/ASTM A249 Stainless Steel Tube

YUHONG GROUP provides the best ASTM A249/ASME SA249 Stainless steel tubes including welded austenitic alloy steel boiler tube, superheater and heat exchanger tube, and U bending tube.

TP304/TP304L Stainless Steel Tube

TP316/TP316L Stainless Steel Tube

ASTM A249 TUBING FEATURES

ASTM A249/ASME SA249 stainless steel tube has good plasticity, low strength, and hardness. At the same time, ASTM A 249also has a certain toughness, but it is not ferromagnetic.

ASTM A249/ASME SA249 stainless steel tube is not only resistant to oxidative acid medium corrosion, but also resistant to sulfuric acid, phosphoric acid, formic acid, acetic acid, urea, etc. if it contains Mo, Cu, and other elements. If the carbon content of ASME SA249/ASTM A249 tubing is less than 0.03% or contains Ti and Ni, the resistance of this SS steel tube to intergranular corrosion can be significantly improved.

ASME SA249/ ASTM A249 TP304 SPECIFICATIONS

|

ASTM A249 Standard |

ASTM A249/ASME SA249 |

|

Tube Type |

Welded Tube |

|

Finishes |

Annealing Pickling, Bright Annealing |

|

Outside Diameter |

6 Up To 304.8 Mm |

|

Thickness |

|

|

Application |

Heat Exchanger System |

GRADES OF SPECIFICATION ASTM A249/SA 249

|

Grade |

Specification |

|

Stainless 304/304L, 304/304H |

ASTM A249/SA249 |

|

Stainless 309S |

ASTM A249/SA249 |

|

Stainless 310S |

ASTM A249/SA249 |

|

Stainless 316/316L, 316/316H |

ASTM A249/SA249 |

|

Stainless 317/317L |

ASTM A249/SA249 |

|

Stainless 321/321H |

ASTM A249/SA249 |

|

Stainless 347/347H |

ASTM A249/SA249 |

ASME SA249/ ASTM A 249 TUBING CHEMICAL COMPOSITION

|

Grade |

UNS |

Composition, % |

||||||||||||||

|

Design |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mb |

Ti |

Nb |

N |

Cu |

Ce |

B |

Al |

|

|

TP304 |

S30400 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|||||||

|

TP304L |

S30403 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|||||||

|

TP304H |

S30409 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|||||||

|

TP310S |

S31008 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

||||||||

|

TP310H |

S31009 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

||||||||

|

TP310H |

S31035 |

. . . |

. . . |

. . . |

||||||||||||

|

TP316 |

S31600 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

||||||||

|

TP316L |

S31603 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

||||||||

|

TP316H |

S31609 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

||||||||

|

TP317 |

S31700 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

||||||||

|

TP317L |

S31703 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

||||||||

|

TP321 |

S32100 |

2 |

1 |

. . . |

Ti 5 × (C+N) min, 0.70 max |

. . . |

. . . |

. . . |

||||||||

|

TP321H |

S32109 |

2 |

1 |

. . . |

4(C+N) min; 0.70 max |

. . . |

. . . |

. . . |

||||||||

|

TP321H |

S32654 |

. . . |

. . . |

. . . |

||||||||||||

|

TP321H |

S33228 |

1 |

. . . |

. . . |

. . . |

. . . |

||||||||||

|

TP321H |

S34565 |

1 |

. . . |

. . . |

. . . |

|||||||||||

|

TP347 |

S34700 |

2 |

1 |

. . . |

. . . |

See Spec |

. . . |

. . . |

. . . |

|||||||

|

TP347H |

S34709 |

2 |

1 |

. . . |

. . . |

See Spec |

. . . |

. . . |

. . . |

|||||||

|

TP348 |

S34800 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

Co 0.20, Ta 0.10 |

||||||

|

TP348H |

S34809 |

2 |

1 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

Co 0.20, Ta 0.10 |

|||||

ASME SA249/ ASTM A 249 TUBING SIZE TOLERANCE

|

OD |

WTH |

L |

||

|

ASTM A249 |

<25.4mm |

±0.10mm |

±10.00% |

OD<50.8mm +3.0mm -0mm |

|

≥25.4mm-38.1mm |

±0.15mm |

|||

|

≥38.1mm-50.8mm |

±0.20mm |

|||

|

≥50.8mm-63.5mm |

±0.25mm |

|||

|

≥63.5mm-76.2mm |

±0.30mm |

OD≥50.8mm +5.0 -0mm |

||

|

≥76.2mm-101.6mm |

±0.38mm |

|||

|

≥101.6mm-190.5mm |

+0.38mm -0.64mm |

|||

|

≥190.5mm-228.6mm |

+0.38mm -1.14mm |

|||

WHAT IS ASME ASTM SA 249 STAINLESS STEEL TUBE?

ASME ASTM SA 249 stainless steel tubes are used in a variety of applications, including boiler, superheater, heat exchanger, and condenser systems. These a249 stainless steel tubes are manufactured through a welding process and are typically made from austenitic stainless steel, although other stainless steel grades may also be used.

The astm a249 tp304 specification outlines the requirements for the manufacturing, dimensions, mechanical properties, and testing of these welded stainless steel tubes. It provides guidelines for various aspects, including tube dimensions, tolerances, chemical composition, mechanical properties, and nondestructive testing methods.

The stainless steel tubes produced under the ASME ASTM SA 249 standard are designed to withstand high temperatures, corrosion, and pressure in demanding industrial environments. ASME sa249 are known for their excellent corrosion resistance, strength, and durability, making them suitable for applications where reliability and longevity are essential.

Common stainless steel grades used in ASME ASTM SA 249 tubes include 304, 304L, 316, 316L, 317, and 321. These grades offer varying levels of corrosion resistance, mechanical properties, and heat resistance, allowing for the selection of the most appropriate grade based on the specific application requirements.

Overall, ASME ASTM SA 249 stainless steel tubes meet stringent industry standards, ensuring that they are manufactured to the specified dimensions, quality, and performance criteria. These ASTM a249 tubings play a critical role in various industrial sectors, providing efficient and reliable solutions for heat exchanger tube manufacturers and fluid transportation systems.

ASTM A249 VS A269 STAINLESS STEEL TUBE

Applications: ASTM A249 tubes are primarily intended for general corrosion-resisting and low- or high-temperature service, including heat exchangers, condenser tubes, and other applications. ASTM A269 tubes, on the other hand, are specifically designed for general service applications requiring high corrosion resistance and mechanical properties.

Manufacturing Process: ASTM a249 tubingis produced through the welding process, while a269 tubing can be either welded or seamless. Seamless ss pipes and tubesare typically preferred for high-pressure or critical applications.

Dimensional Tolerances: ASTM a249 tubinghas more lenient dimensional tolerances compared to ASTM A269. A269 tubes have tighter tolerances for outside diameter, wall thickness, and length, ensuring greater precision and consistency.

Surface Finish: ASTM A269 specifies stricter requirements for the surface finish of tubes, particularly for applications where cleanliness and smoothness are important, such as in the pharmaceutical and food processing industries.

Send product request

Other supplier products

| ASTM A213/ASME SA213 STAINLESS STEEL TUBE PROVIDED BY YUHONG | ASTM A213 tube/ASME SA213 Stainless Steel Tube YUHONG GROUP provides the best ASTM stainless steel tube/ASME SA213 Stainless steel tubes including... | |

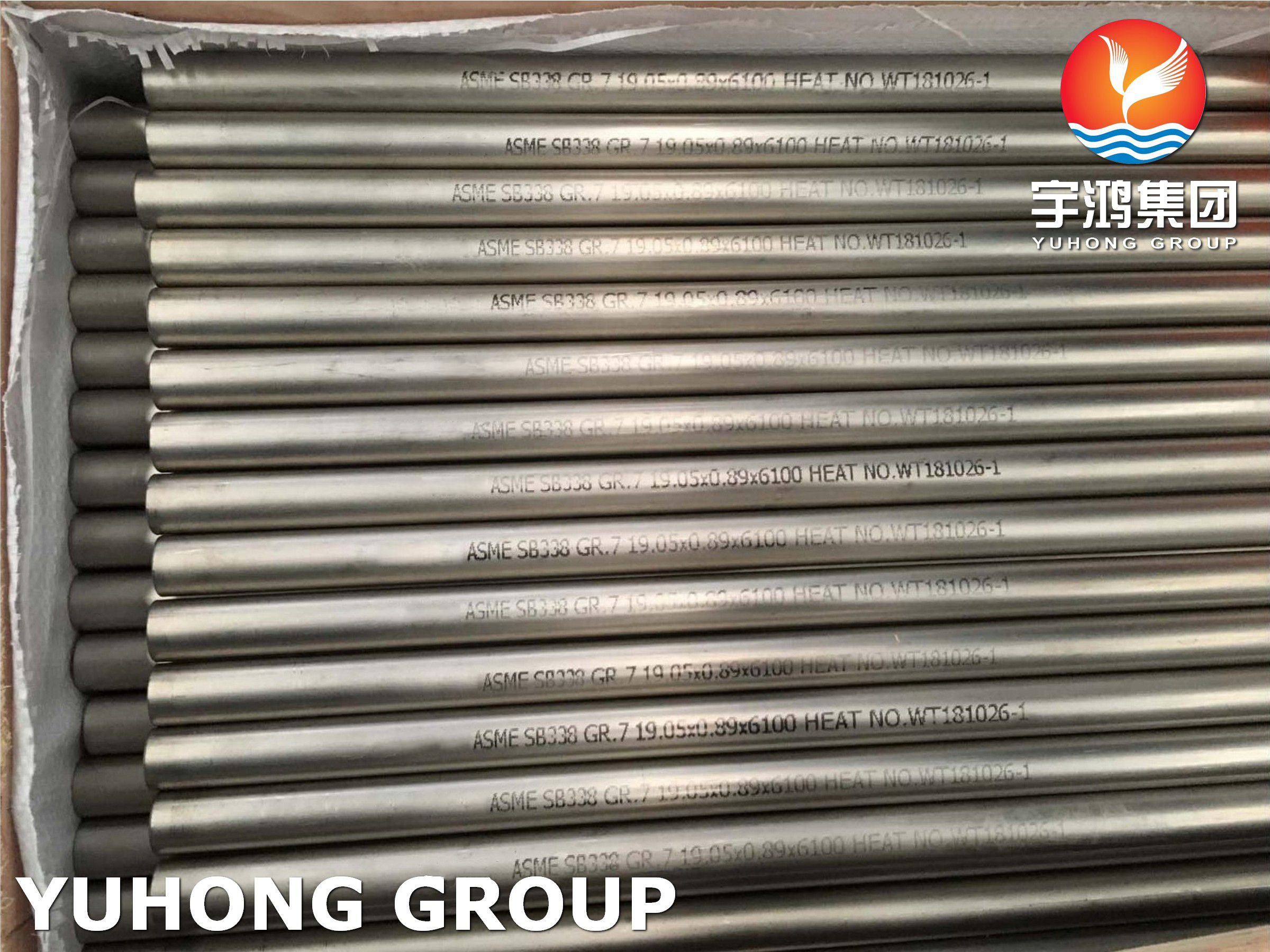

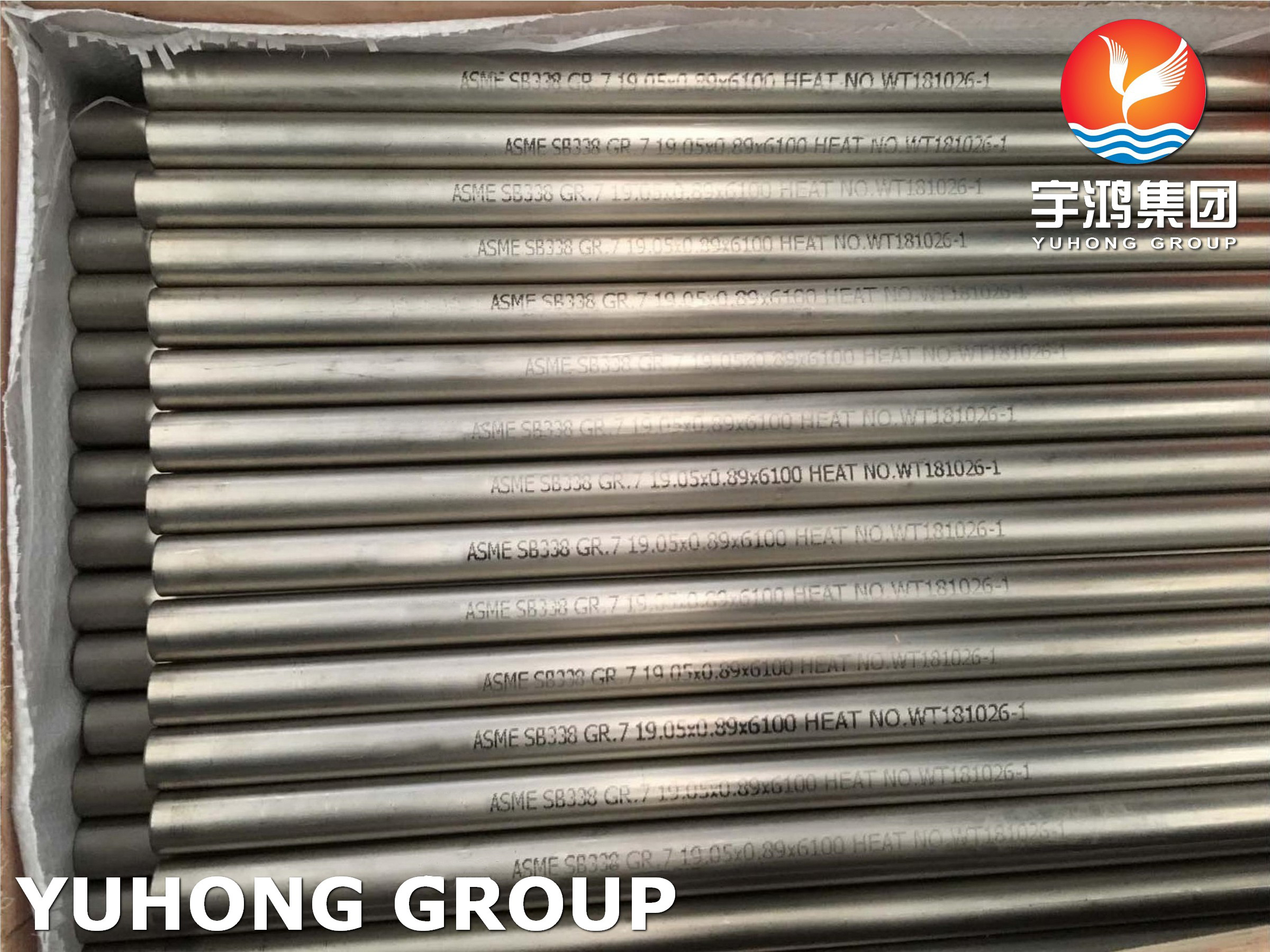

| ASTM B338/ ASME SB338 TITANIUM ALLOY STEEL TUBE | ASTM B338/ ASME SB338Titanium Tube (Ti Tube) has a superior strength-to-weight ratio and corrosion resistance is one of the common titanium product... | |

| ASTM B338/ ASME SB338 TITANIUM ALLOY STEEL TUBE | ASTM B338Titanium Tube (Ti Tube) has a superior strength-to-weight ratio and corrosion resistance is one of the common titanium products. We genera... | |

| ASTM B111/ ASME SB111 COPPER ALLOY STEEL TUBE | ASME SB111 C70600 Tube Copper-nickel alloy that resists seawater corrosion and has high antifouling properties against marine microorganisms. You c... | |

| NICKEL ALLOY STEEL PIPE /TUBE | Nickel alloys are one of the most useful materials for manufacturing technically superior nickel pipeand nickel tubefor industrial applications. Th... |

Same products

| Galvanized Steel Grating for Drainage | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

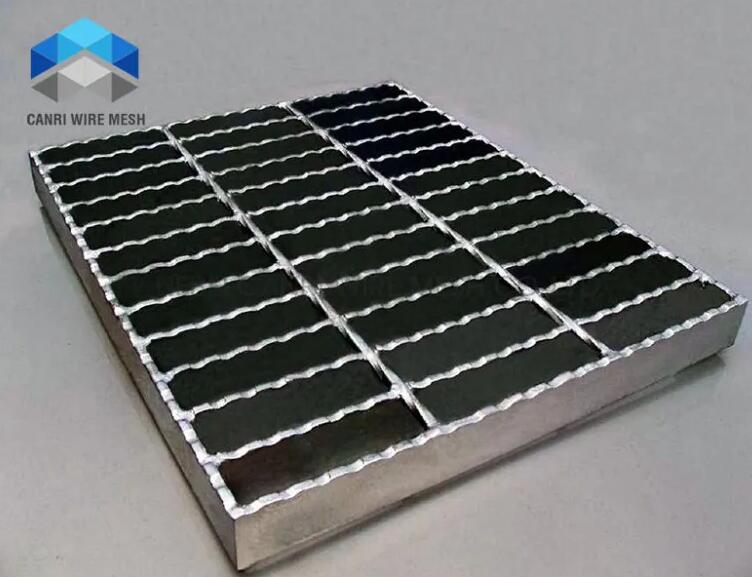

| Serrated Bar Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... | |

| Galvanized Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating Galvanized steel gratingis an ideal product for wet, slippery situation... |