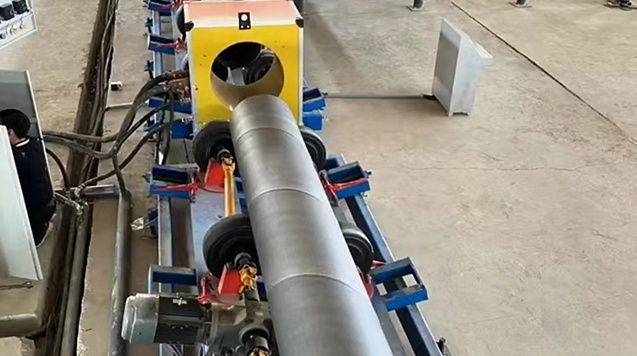

Anti-corrosion and Insulated Steel Pipe Production Line

An anti-corrosion and insulatedinternal pipe coating equipment, internal pipe coating machineproduction line is a specialized system used for manufacturing steel pipes that are resistant to corrosion and have insulation properties. This internal pipe coating equipmenttypically includes equipment such as an uncoiler, forming mill, insulation layer injection machine, anti-corrosion coating machine, curing oven, and cutting machine. The polyurea internal pipe coatingproduction line is designed to apply protective coatings and insulation materials to steel pipes, ensuring their durability and thermal efficiency. This coating for underground pipingtechnology is commonly used in industries such as oil and gas, thermal power, and chemical processing, where pipe corrosion and insulation are critical factors.

THE IMPACT OF ANTI-CORROSION AND INSULATION ON STEEL PIPE QUALITY AND DURABILITY

Anti-corrosion and insulation are two essential factors that significantly impact the quality and durability of steel pipes. Corrosion can weaken the structural integrity of steel pipes over time, leading to leaks and failures. Therefore, implementing effective anti-corrosion measures is crucial to extend their lifespan.

Anti-corrosion coatings and treatments create a protective barrier on the outer surface of the pipes, preventing contact between the steel and corrosive environments such as moisture, chemicals, and saltwater. This barrier inhibits the formation of rust and corrosion, thereby enhancing the overall durability of the steel pipe.

Similarly, insulation plays a vital role in maintaining the quality of steel pipes, especially in applications where temperature variations are significant. Insulation helps minimize heat loss or gain, which can affect the structural integrity of the pipes. By preventing thermal stresses, insulation reduces the likelihood of cracking, deformation, and premature failure.

Overall, the implementation of anti-corrosion and insulation measures significantly enhances the quality and durability of steel pipes, ensuring their longevity and reliable performance in various applications.

THE ROLE OF ANTI-CORROSION AND INSULATED STEEL PIPES IN INFRASTRUCTURE DEVELOPMENT

Anti-corrosion and insulated steel pipes play a crucial role in infrastructure development. They are widely used in various sectors such as oil and gas, water distribution, sewage systems, and construction.

One of the main benefits of anti-corrosion coatings on steel pipes is the prevention of corrosion. In infrastructure projects, steel pipes are exposed to harsh environmental conditions, including moisture, chemicals, and saltwater. Without proper protection, corrosion can weaken the pipes over time, leading to leaks, structural failures, and costly repairs. By providing a protective barrier, anti-corrosion coatings extend the lifespan of steel pipes, ensuring their reliability and reducing maintenance requirements.

Insulated steel pipes are essential in applications where temperature control is necessary. These pipes are commonly used in industries such as heating, ventilation, and air conditioning (HVAC) systems, where maintaining consistent temperatures is crucial. Insulation reduces heat loss or gain, ensuring efficient energy transfer and minimizing the risk of thermal stresses on the pipes. This, in turn, enhances the overall performance and durability of the infrastructure system.

In summary, the use of anti-corrosion and insulated steel pipes in infrastructure development is vital for ensuring the longevity, reliability, and performance of various systems. These measures contribute to the overall sustainability and efficiency of infrastructure projects, reducing maintenance needs and operating costs in the long term.

HOW ANTI-CORROSION AND INSULATED STEEL PIPE PRODUCTION LINES WORK

Anti-corrosion and insulated steel pipe machine starts with the raw materials. High-quality steel is selected, which is typically low carbon or alloyed steel with excellent corrosion resistance properties.

The first step in production is surface preparation. The steel pipes are thoroughly cleaned to remove any dirt, rust, or mill scale. This is usually done through methods such as shot blasting or pickling.

Anti-corrosion coatings are then applied to the cleaned pipes. There are various coal tar epoxy pipe coatingoptions available, such as epoxy, polyethylene, or polypropylene. These coatings are typically applied through processes like extrusion, wrapping, or spraying.

Insulation is added to the coated pipes to provide thermal protection. Common insulation materials include foams such as polyurethane or polystyrene, as well as mineral wool or fiberglass insulation. The insulation is usually applied by wrapping or spraying methods.

After the anti-corrosion and insulation processes, the pipes may undergo additional curing or drying stages to ensure the coatings and insulation are properly bonded and set.

Finally, the finished pipes are subject to quality control checks, which may include testing for coating thickness, adhesion, insulation efficiency, and overall product durability.

The completed anti-corrosion and insulated steel pipes are then ready for distribution and use in various infrastructure projects, providing long-lasting, corrosion-resistant, and thermally efficient solutions.

Now the price of internal pipe coating equipment for saleis reasonable, if you are interested, please contact us.

We can also offer sorts of high quality pipe production line chinafor sale, if you have needs, please leave us a message.

Send product request

Other supplier products

| HIGH FRENQUENCY WELDED STEEL PIPE PRODUCTION LINE | A high frequency pipe welding machineis a system used for manufacturing steel pipes with high-frequency welding technology. The welded pipe product... | |

| 3PE ANTI-CORROSION STEEL PIPE PRODUCTION LINE | The 3LPEAnti-corrosion Steel Pipe Production Line is a specialized system used for manufacturing steel pipes with a triple-layer coating designed t... | |

| STAINLESS STEEL SPIRAL WELDED PIPE PRODUCTION LINE | The stainless steel spiral welded pipeunit adopts front-swing intermittent production, which is a complete set of spiral steel pipe manufacturingma... | |

| PLASTIC COATED STEEL PIPE ANTI-CORROSION PRODUCTION LINE | The main function of plastic coated brake pipeanti-corrosion production line is to use the oxide layer on the resin surface to bond the steel pipe ... | |

| ANTI-CORROSION AND INSULATED STEEL PIPE PRODUCTION LINE | An anti-corrosion and insulated internal pipe coating equipmentproduction line is a specialized system used for manufacturing steel pipes that are ... |

Same products

| Seamless pipe | Seller: Eastern Steel Manufacturing Co.,Ltd | Seamless pipe is a long steel strip with a hollow cross-section and no seams around it. &zw... | |

| Seamless Steel Pipe | Seller: Shandong Xin Jiyuan Special Steel Tube Co., Ltd | Seamless steel pipeis perforated by the whole round steel,and the steel pipe with no weld on the ... | |

| tool steel manufacturer | Seller: SHANGHAI JIEBAO METAL CO.,LTD | tool steel manufacturer Tool Steel is a high-quality steel specifically designed for use in... | |

| galvanized coil | Seller: Hunter Special Steel Company Limited | galvanized coil Hot Dipped Galvanized Steel Coils refers to the process of applying a prote... | |

| Cold Rolled Square And Rectangular Tubes | Seller: Tianjin Muchang Materials Imp.& Exp. Corp | Cold rolled black square and rectangular pipesare the precise choice for modern engineering and m... |