Shot Blasting Booth

Trolley sand blasting booth is special equipment designed to meet specific process requirements. Through sandblast cleaning, the dirt, oxide scale, welding slag and waste paint on the surface of the complex workpiece can be removed, the surface of the workpiece can be smooth, the internal stress of workpiece can be reduced, the surface of the workpiece can be strengthened, and the purpose of improving the surface and internal quality of workpiece can be achieved.

Equipment Components of Sand Blasting Booth

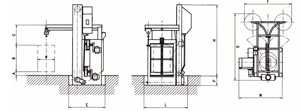

This machine is a special flat trolley sandblasting booths equipment. It consists of grit blasting system, flat trolley conveying system, sand blasting tank, pneumatic scraper system, screw conveyor, elevator, separator, sand abrasive control system, lighting system, dust removal system and electric control system etc.

Advantages of Shot Blasting Booth

The chamber body is made of steel plate and section steel, and its structure is strong.

The main body of the equipment is a strong and durable steel structure, lined with wear-resistant rubber guard plate, and the side of the chamber body is provided with a safety door. There are doors on one side of the chamber body, lighting lights on the top and side of the chamber body to maintain sufficient brightness in the room. The brightness of the interior is over 400 lux. The air supply outlet is designed on the side of the room body, and the air suction outlet is designed on the top of the equipment, which effectively avoids the dust rising and improves the indoor visibility and the working environment of workers. The upper part of the scraper is provided with a grid plate and a leak-proof plate. In order to decrease the depth of the pit, we adopt pneumatic scraper device and screw conveying structure.

More About shot grit blasting boothplease contact our sales representative.

Application of Shot Blasting Booth

The equipment uses manual shot peening to remove surface rust. The surface finish and roughness of the cleaned workpiece meet the relevant international standards. Removal of dirt, oxide scale, welding slag and waste paint on the surface of complex workpiece can make the surface of workpiece smooth, reduce the internal stress of workpiece and strengthen the surface of workpiece in order to improve the adhesion and anti-corrosion ability of paint.As the grit blasting machine manufacturers, we have grit blaster for sale, welcome to buy.

As the shot blasting equipment suppliers, Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. It is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. Sand blasting Machines clean or shape a surface using sand material known as abrasive which is propelled using high pressure typically through compressed air or blast wheel. Sand Blasting Machine are many types such as Sandblasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines and so on.

Shot Blasting Room

Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. The shot blasting chamber is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The best sandblasting equipment clean or shape a surface using sand material known as abrasive which is propelled using high pressure typically through compressed air or blast wheel. So you can call it air blasting equipmentor air powered sandblaster. Sand Blasting Machine are many types such as Sandblasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines and so on.

Send product request

Other supplier products

| Hook Type Shot Blasting Machine | Hook shot blasting machineis suitable for cleaning the foundry part, construction, chemical engineering, machine tools and many other industries of... | |

| Shot Blasting Machine | As one of the professional shot blasting equipment manufacturers, BH offers a wide range of high-quality shot blasting machines to satisfy differen... | |

| Shot Blasting Room | Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cind... | |

| Floor Shot Blaster | The floor shot blasting equipment for saleis the shot blasting machine that ejects the shot material (steel shot or sand) at a high speed and a cer... | |

| Floor Shot Blaster | The floor shot blasting equipment for saleis the shot blasting machine that ejects the shot material (steel shot or sand) at a high speed and a cer... |

Same products

| AEMK 588 Loader | Seller: AEMK MACHINE CO.,LTD | Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ... | |

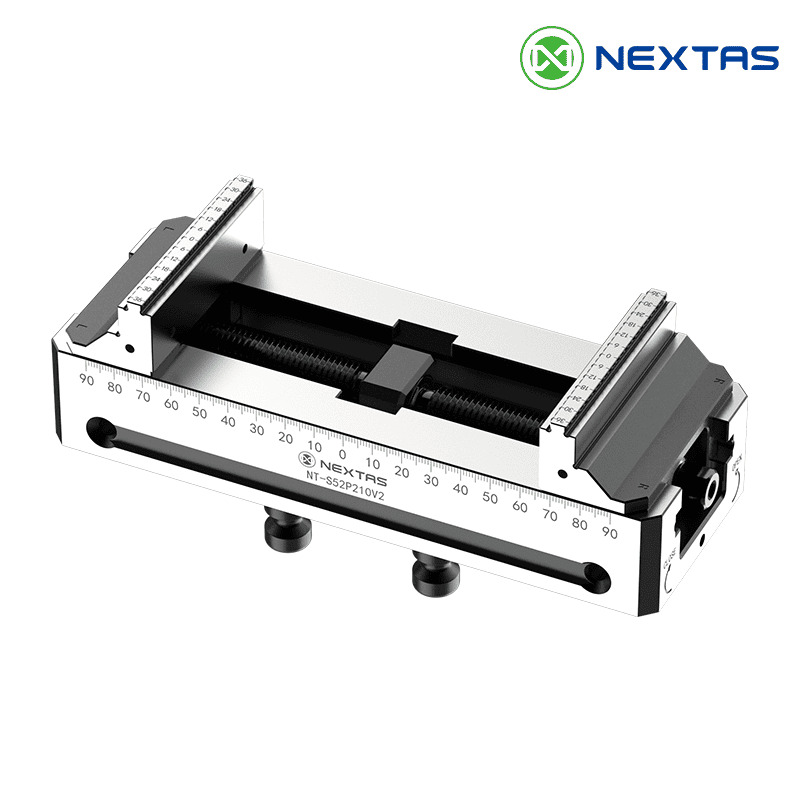

| Quick Change Worktable | Seller: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

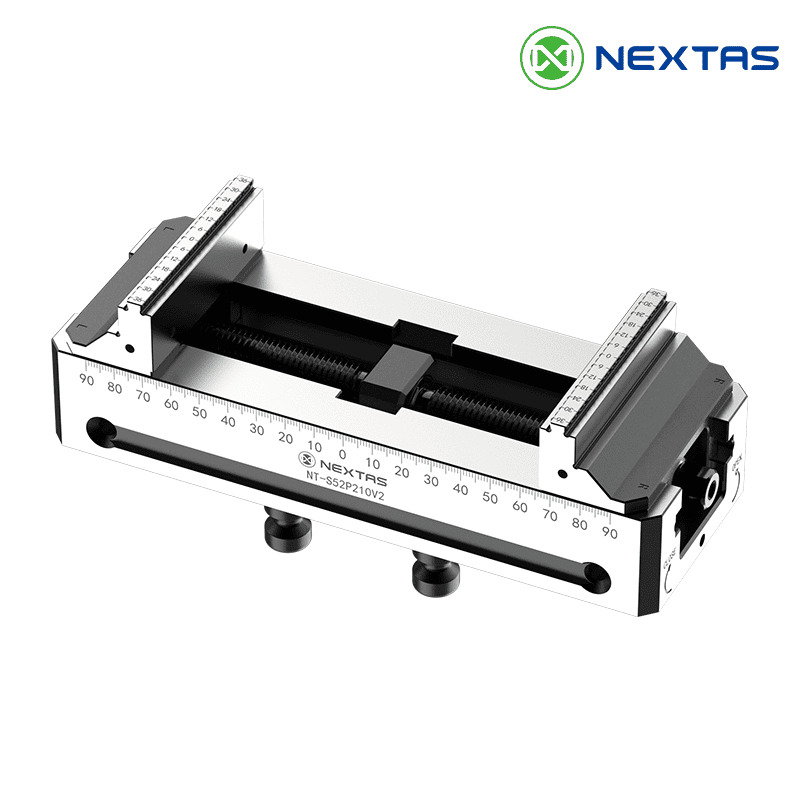

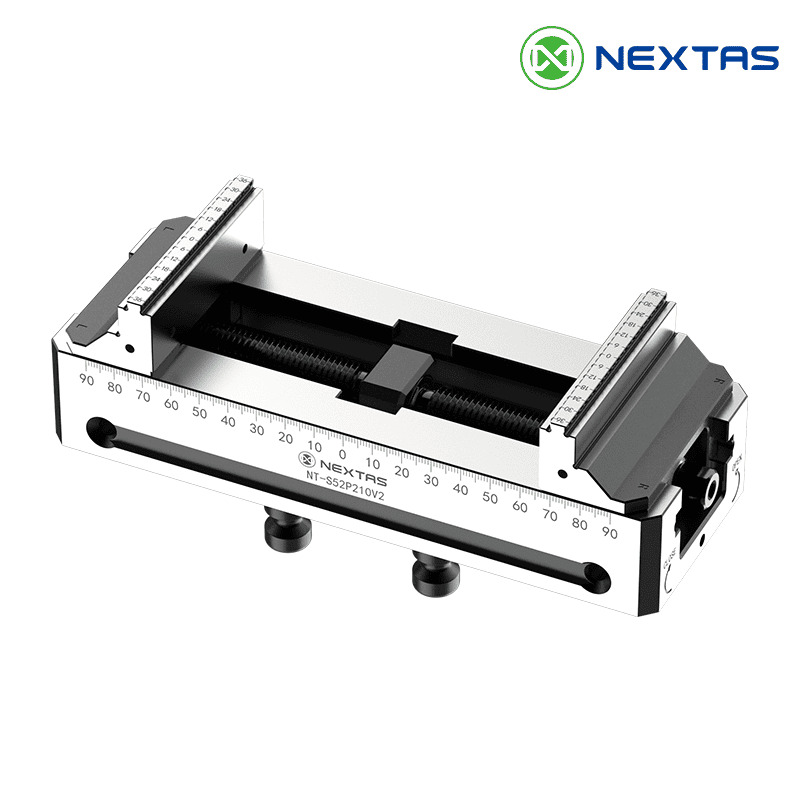

| Self Centering Vise | Seller: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Seller: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Seller: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |