How to Optimize the Plates of Jaw Crushing Machine?

As we all know, the operation of jaw crushing machine is mainly driven by the mutual work of movable jaw plates and static jaw plates. As one of the most important part for China jaw crusher, the movable jaw plate is also one of the relatively heavy part. The design of movable jaw plate is directly related with the crushing effect of jaw crushing plant. As a professional, FTM Crusher Company has done a lot of efforts to improve the performance and technological level of jaw crusher machine.

While, the key factor for these efforts is to optimize the design of jaw plates. Then, how to optimize the design of jaw plates? The following content will give you answers. At present, most jaw crushers on the market are relatively heavy in volume. While, the movable jaw plates are relatively heavy in the whole China jaw crusher. Therefore, if the strength is enough, efforts on reducing the weight of movable jaw plate are the technological breakthroughs of design optimization.

In order to satisfy the stress condition and reduce the weight on movable jaw plate,has changed the rectangular reinforcing rib into the trapezoid reinforcing rib. Since technological processes like welding and forging can influence the performance and quality of jaw plates and whole jaw crushing plant, FTM thinks that it is necessary to improve the welding and forging technologies. If you want to know more about the jaw crushing plant, please feel free to visit our website and leave messages our it or directly us. We will give you a professional configuration and quotation.

Fote Heavy Machinery:

Fote Official Email:

Send product request

Other supplier products

All supplier products

Importance of Wood Pellet Mill for Energy Structure

Featured in the high thermal efficiency, wide application ranges and easy storage, biomass particles can be used as the ideal substitutes of natura...

Ways to Improve Pellet Quality of Straw Pellet Mill

With the ability to turn agricultural and forestry wastes into biomass pellets of great value, straw pellet mill is becoming more and more popular ...

Orders for Running the Fote Coal Ash Dryer

Before working normally, lignite dryer generally needs a period for adaption. This period lasts for about 3 days. If there is nothing wrong with th...

Role of FTM Wood Pellet Mill for Resource Supply

At present, the development of wood pellet mill offers new solutions for people to deal the energy issue. What’s more, to develop the biomass...

Working Principle of FTM Impact Crushing Machine

Among all crushers, impact crusher and cone crusher are mainly used for the secondary and tertiary crushing. While, in aspects of crushing principl...

Same products

AEMK 588 Loader

Seller: AEMK MACHINE CO.,LTD

Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ...

Quick Change Worktable

Seller: Nextas Co.,Ltd

Quick Change Worktable

Zero Point Pneumatic Chuck

Zero Point Positioning Datum System

NE...

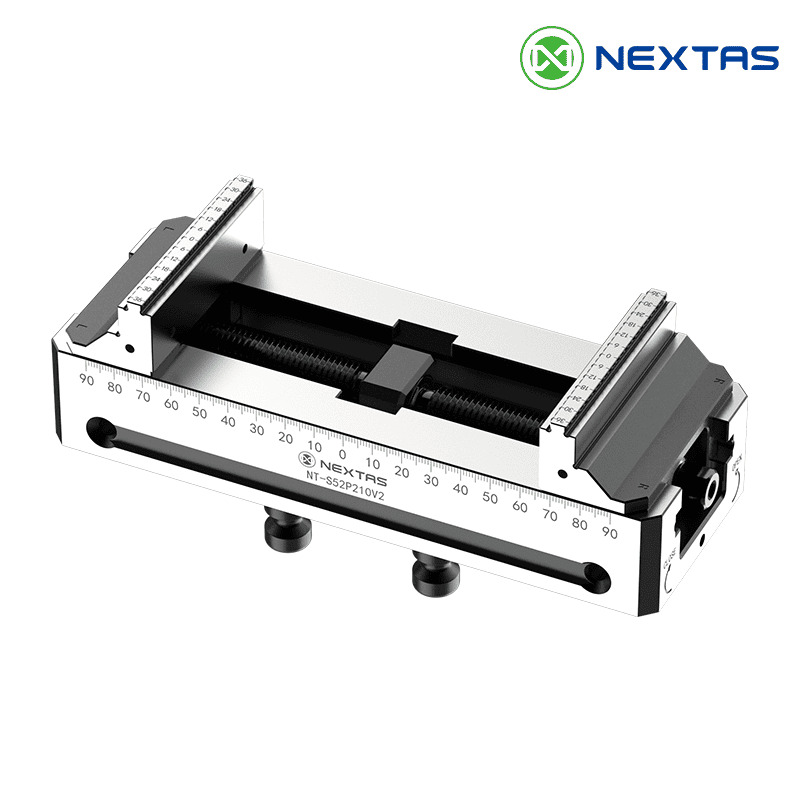

Self Centering Vise

Seller: Nextas Co.,Ltd

Self Centering Vise

Key Advantages

High precision: repeatability as tight as ≤ 0.005 mm ...

BDS Positioning Chuck

Seller: Nextas Co.,Ltd

BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that...

Quick Change Pallet System

Seller: Nextas Co.,Ltd

Quick Change Pallet System

Quick Change Pallet System

Quick Change Pallet System delivers m...