Leaf Spring

Leaf spring is a very important part of a vehicle.

Ultraton semi trailer leaf springshave the advantages of good reliability, simple structure, short manufacturing process flow, low cost and greatly simplified structure. They are widely used and very popular.

It is known that the semi truck leaf springs are composed of many pieces of steel that are elastic, uniform in width and thickness, and of different lengths. Its function is to connect the frame and the axle with the form of suspension, which is exposed between the frame and axle to bear the impact of the wheel load on the axle, reduce the body's violent vibration, and maintain the ride stability and adaptability to different road conditions.

Leaf spring is a rectangular section of the long arc spring steel. Usually, the processing technology of automotive leaf spring is blanking, straightening, drilling, winding, quenching & medium tempering, shot blasting, assembly, precompression. In the most common semi trailer leaf springs configuration, the center of the arc provides the position of the axle, while the ring formed at either end is attached to the vehicle chassis.

For very heavy vehicles, leaf springs can be made from multiple blades stacked together, often with progressively shorter blades. Leaf springs can be used for positioning and a certain degree of damping as well as spring functions.

Flat rectangular steel plate is curved, with several pieces of stacked chassis with spring, one end is installed on the hanger with a tip, the other end is connected to the girder with a lifting lug, so that the spring can be telescopic, suitable for medium and large cargo trucks.

According to the principle test of motion mechanics, it is proved that when the motion frequency increases, the temperature of a steel piece will increase, the strength will decrease, and the stress concentration point will show strong lines and gradually expand and deepen, and the fatigue limit will be damaged. The same is true of leaf springs, except that they are more elastic and last longer than ordinary steel parts. Leaf spring fracture in addition to other reasons, the main reason is caused by poor lubrication, should cause the driver and technical management personnel to pay attention to timely lubrication of leaf spring, in order to reduce the friction dispersion stress and prevent the steel sheet surface from pulling, to reduce the invasion of dust, soil and water to prevent corrosion, and for cooling heat, prevent the decline of elastic strength.

Why Ultraton SemiTrailer?

Our container semi-trailer has a reasonable structure, reliable performance, sophisticated technology, and the full potential of the vehicle.

It is specially used for the transportation of various containers and can be used repeatedly for a long time with sufficient strength.

Ultraton has container transport semi trailers for sale, it depends on the customer's requirements for the size and configuration of the tonnage to sign the specific contract price.

Send product request

Other supplier products

| 3 Axles 55T Flatbed Container Transport Semi Truck Trailer | If you need more loading capacity, Ultraton's 3 axles 55T Flatbed Semi Trailer for standard size of container can meet your different need on conta... | |

| 30T Terminal Port Container Truck Semi Trailer | Ultron's 30T Container Terminal Semi Trailer is an ideal and practical way to handle containers by Low-speed tractors in specific areas such as ter... | |

| SEMI END DUMP TRAILER | The Ultratonsemi end dump truck and traileris equipped with an automatic dumping device, which can automatically dump at a certain angle for unload... | |

| Skeletal Semi Trailer | We have skeletal trailer for sale!What is skeletal trailer ? Skeletal Semi Trailer has no bottom plate and can only be used for transporting conta... | |

| Leaf Spring | As one of the top semi trailer suppliersin China, ULTRATONhas been working on supplying high quality semi trailers such as truck trailer and contai... |

Same products

| AEMK 588 Loader | Seller: AEMK MACHINE CO.,LTD | Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ... | |

| Quick Change Worktable | Seller: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

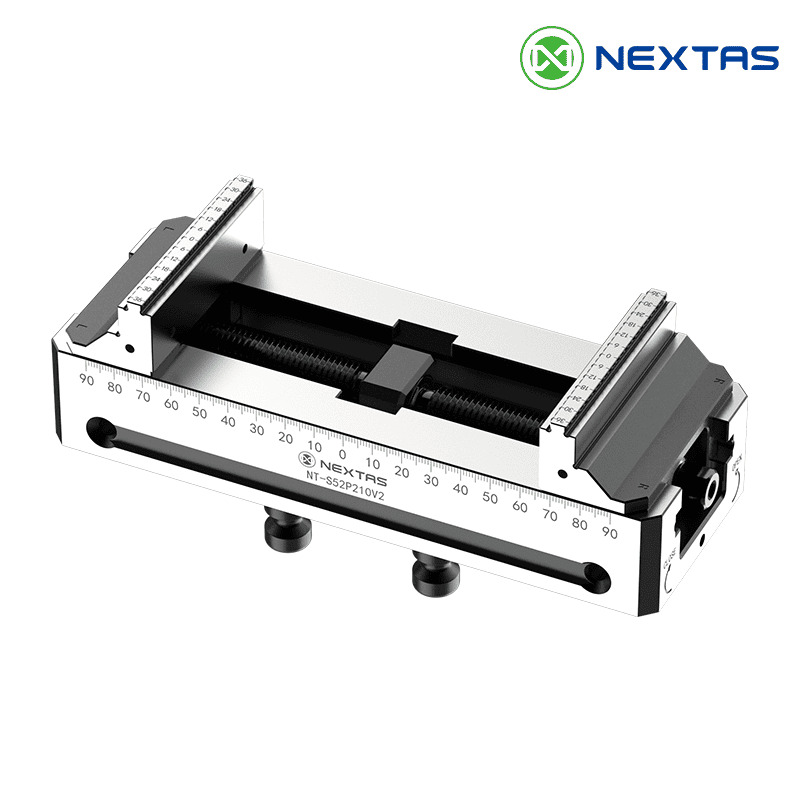

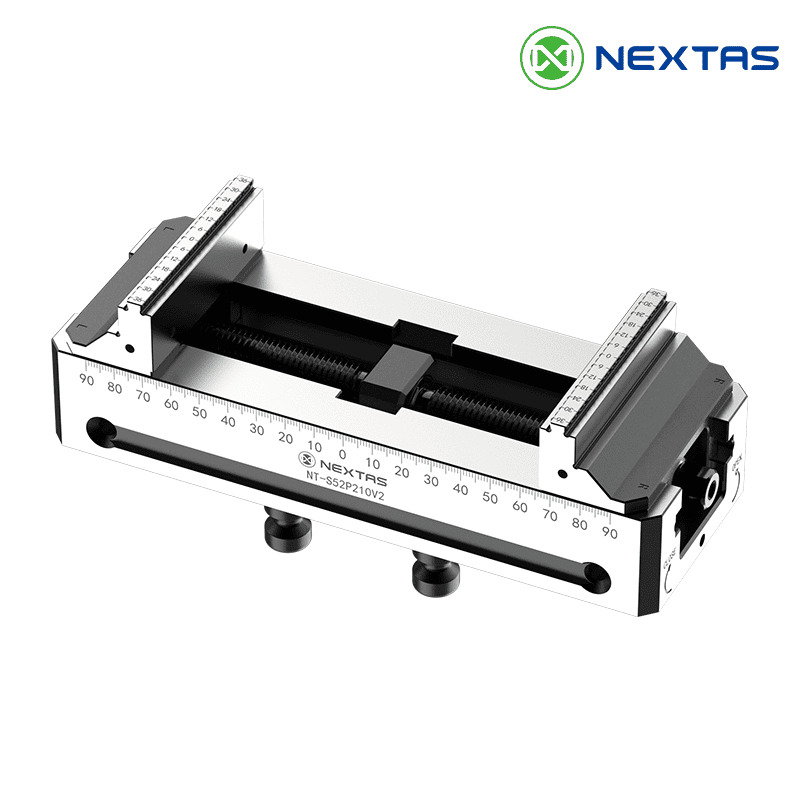

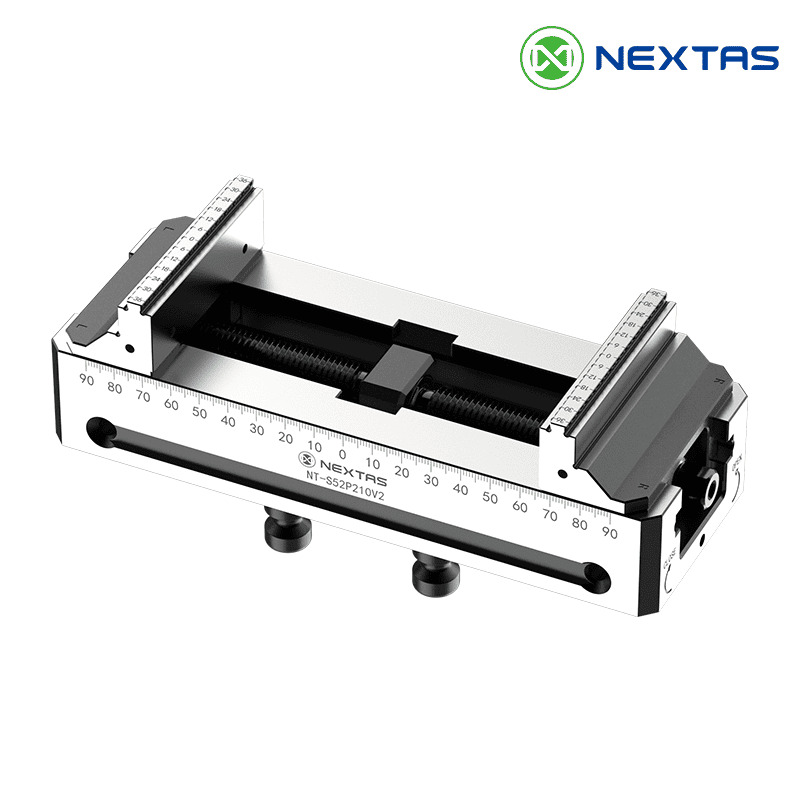

| Self Centering Vise | Seller: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Seller: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Seller: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |