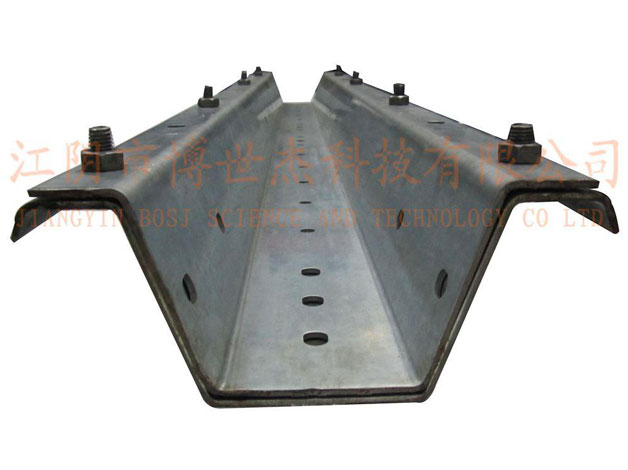

STEEL ROLL FORMING MACHINE

Overview of Steel Roll Forming Machine

Cold forming is a new technology and new technology for metal sheet forming, material saving, energy saving and high efficiency. By using this process, not only can high-quality steel products be produced, but also the cycle of product development can be shortened and production efficiency can be improved, thereby improving the market competitiveness of enterprises. Fifth, in the past half century, cold bend forming has developed into the most effective sheet metal forming technology. 35%~45% of the strip rolled in North America is processed by cold-bending into more products than steel used in the automotive industry.

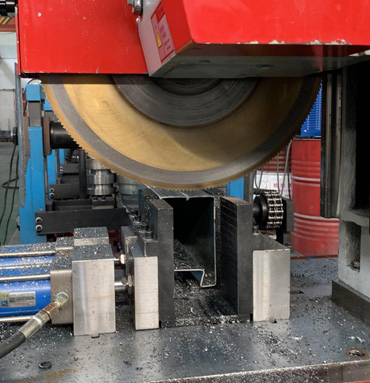

Steel Roll Forming Machine Operation:

First, before using the stell roll forming machine, be sure to check the machine first and make a complete set of protective steps.

Second, when using the machine, be sure to check whether the upper and lower molds are firm and fit together, and check the positioning device at each point to meet the processing requirements.

Third, you can let the machine idle for one to two minutes before use, and return the parts to the original position. Confirm that there are no defects and problems before proceeding to the next step.

Fourth, when manipulating the steel roll forming machine, it is best to be commanded by one person, and others are obeying the command. This avoids the problem of multi-person operation and confusion.

BOSJ established in 2004, as a professional china roll forming machine manufacturer,BOSJ has won a worldwide reputation in this field. Our products have broad markets in Southeast Asia, India, North and South America, Western Asia, Russia, and Australia. Want to know more, please contact us.

Send product request

Other supplier products

| CORRUGATED SHEET ROLL FORMING MACHINE | Metal roofing roll formeris Suitable for simple roof construction, it is the most economical system in thin metal roofing systems. It is widely use... | |

| Galvanized Steel Silo Upright Double Layer Roll Forming Machine | BOSJ estabilished in 2004, As one of theleading roll forming machine manufacturers in china,BOSJ has won worldwide reputation in this field. Our pr... | |

| LIGHT GAUGE STEEL FRAMING C PURLIN ROLL FORMING MACHINEE | BOSJ Light Gauge Steel Roll Forming Machine is suited to construct walls, floors and roofs for 1 – 3 level residential, modular and transport... | |

| PIPE ROLL FORMING MACHINE | The pipe roll forming machine is a high-quality, high-efficiency rounding device for winding carbon steel, stainless steel and non-ferrous metal pr... | |

| CORRUGATED SHEET ROLL FORMING MACHINE | Corrugated sheet roll forming machineis Suitable for simple roof construction, it is the most economical system in thin metal roofing systems. It i... |

Same products

| Cable Pulling Sock | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Pulling Sock CABLE PULLING SOCK: The is the most ideal tool designed for electrical a... | |

| Side Dragging Cable Grip | Seller: Hebei Long Zhuo Trade Co., Ltd | Side Dragging Cable Grip Side Dragging Cable Grip SGA/MGT/SK/MK is also called cable sock w... | |

| Cable Pulling Grips TG MG TGM TGK | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Pulling Grips TG MG TGM TGK Head Traction Cable Grip TG/MG/TGM/TGK Cable grips are a ... | |

| Cable Grip Supplier | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Grip Supplier Cable Grip: A Reliable Solution for Safe Cable Pulling and Handling A... | |

| Cable Roller Manufacturer | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Roller Manufacturer Cable Roller: Essential Equipment for Safe and Efficient Cable Ins... |