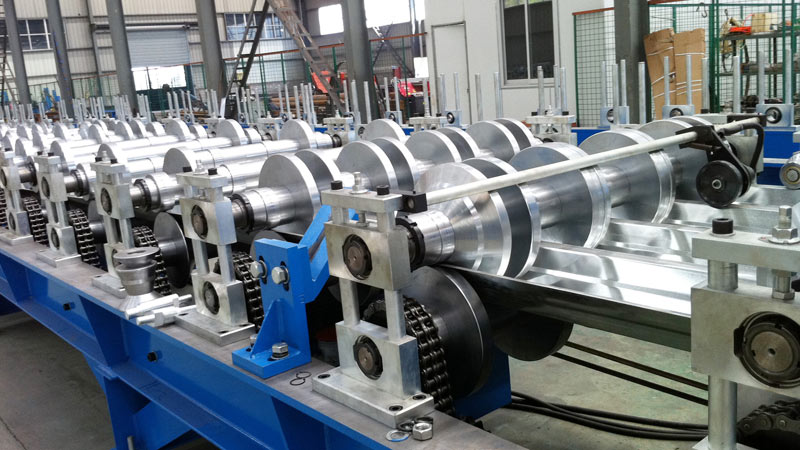

High Frequency ERW Pipe Mill Line

High frequency welded pipe mill Line is mainly used for making ERW welded steel pipes. ERW is short for Electric Resistance Welding. At present, ERW pipe occupies a decisive position in the field of conveying pipe in the world. Our high-frequency erw steel pipe mill is featured with the advantages of high production efficiency, low cost, material saving, and easy automation.

Main Technical Parameters of ERW Pipe Mill For Sale (For reference only, will be as requests)

A: suitable strip coils

1. Suitable material: Carbon steel coil;

Alloy Steel Coil; API5L X42-X80

(For reference only, will be as requests)

2. Suitable strip width range: 13mm-2261mm

3. Wall Thickness: 0.2mm-22mm

B. Finished products

1.Pipe O. D. φ4mm-φ720mm

2.Thickness: 0.2mm-22mm

3.Square tube: 6mmx6mm-600mmx600mm, thickness: 0.3mm-22mm

Length: 6m-12m

Length tolerance:+/-3mm

C.Equipment data (for reference only)

Production speed: 20-120m/min

Direction: Left to right or right to left from operator's side(as requests by customer)

Capacity: 10,000 ton/year-180, 000 ton/year

Electricity input power: 50kW-1400kW

Foundation: 40m–400m (length) x 3.8m-40m (width)

Weight: About 30ton–300ton.

Operator: 6-8 people (as size requests)

What is ERW Pipe?

Regarding its classification, ERW pipes can be roughly divided into 2 forms of ERW AC welding steel pipes and ERW DC welded steel pipes. And according to a different frequency, ERW seam-welded tubes can also be classified into low-frequency welding pipes, medium frequency welding pipes, and supercurrent welding pipes. Normally, high-frequency welding is mainly used in the production of thin-walled pipes or ordinary wall-thick ERW pipes, and high-frequency soldering is also divided into contact welding and induction welding. Currently, the ERW pipe is mainly used in tap water engineering, the petrochemical industry, the chemical industry, the electricity industry, agricultural irrigation, and urban construction. Concerning the significance of the ERW pipes in various industries, it is then of great importance to choose reliable ERW pipe manufacturing machines. And Hangzhou Roll Forming Technology can help you with that!

As a professional erw pipe mill factory, we provide tube mill line, steel coil upender, coil upender, square pipe forming machine, welded erw tube mill, hf tube mill, erw tube mill line, high frequency welded pipe mill, china downspout machine and etc. Contact us to know more.

Other supplier products

|

|

Large Diameter Spiral Pipe Mill |

A spiral pipe mill machine is used to roll the low carbon steel/ low alloy steel strip into a tube by a certain forming angle and further weld it i... |

|

|

High Speed Tube Mill Line |

High Speed Tube Mill Line is used to produce tube diameter between φ4mm to φ50mm. The top working speed of this tube mill line can reach as... |

|

|

CNC FOLDER |

Hangzhou Roll Forming Technology, a professional CNC folding machine supplier, has high-quality sheet metal cnc folder for sale. The numerical cont... |

|

|

Direct Square Tube Mill Line |

Direct Square Tube MillLine is mainly used to produce the square and rectangular tubes directly, from square to square or rectangular to rectangula... |

|

|

High Speed Metal Deck Roll Former |

Fully automatic, our high speed rollformer is designed with a Cassette-type platform and a quick-change machine base so as to better achieve multi-... |

All supplier products

Same products