Reliable Biomass Pellet Production Line Manufacturer

Biomass pellet fuel is used under the conditions of the pressure roller and ring die of sawdust, straw and other raw materials caused by extruding. The density of raw material, generally about 130 kilograms/stere, forming of the grain density is more than 1100 kilograms/stere, transportation, storage is extremely convenient, at the same time, the fuel performance greatly improved. Compared with other biomass energy technology, biomass pellet fuel technologies are easier to implement mass production and use, use the convenience of biomass granule can be comparable to gas, fuel and other energy. So, the use of reliable biomass pellet production line with national industrial policy, has good economic and social benefits.

Biomass raw materials containing cellulose, hemicellulose, and wood main element. Because structure is loose, density is small, when the external force, the raw material will rearrange the location, mechanical deformation, plastic deformation stage, the elastic and viscoelastic cellulose molecules between winding and twisted, volume was reduced, the density increases.

The Main Equipment of Reliable Biomass Pelle Production Line:

1. The Bucket Elevator

In this project at the entrance of the pellet machine, particles at the exit of the machine before packing must have material conveying equipment, we according to the characteristics of the material and process characteristics, choose the bucket elevator. Bucket elevator machine has the cross sectional area is small, cover an area of an area small, transport system layout is compact, hoisting height is big, good sealing, etc.

2. The Counterflow Cooler

Squeeze out the temperature of the particles in 55 ℃ to 65 ℃, so in front of the packaging must be dry and cool. According to the characteristics of the larger particles, using the counterflow cooler, it mainly cold wind through the surface of material, in order to achieve the purpose of drying and cooling. Material in the process of cooling, in static state, the need to pay attention to the choice of air as opposed to a material flow direction, in order to achieve the effect of the cooling uniformity.

3. Biomass Pellet Machine

The biomass pellet machine is the core of equipment system, its technical performance fit and unfit quality directly affects the whole system. Through on the relationship between the molding pressure and density of pellet fuel and normal temperature conditions, the researches on the mechanism of the density forming types according to different raw materials we choose different ring die parameters, thus can obtain the high density of pellet fuel of low energy consumption of the molding conditions.

.jpg)

As a professional reliable biomass pellet production line manufacturer in China, Henan Fote Heavy Machinery Co. Ltd. provides various high quality biomass pellet plant and biomass pellet machine. Welcome to contact or visit.

Contact Infomation

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

Send product request

Other supplier products

| Latest Advanced Ring Die Rice Husk Pellet Mill for Sale | Rice husk, the main by-product from rice milling, is the most suitable raw material for pelletizing . Therefore, the rice husk pellet mill has good... | |

| New Design Efficient Wood Pellet Mill for Sale | In terms of use, wood pellets are becoming more and more popular in a large scale. To exemplify just a few, they can be used in municipal buildings... | |

| High Efficient and Quality Coconut Shell Pellet Mill for Sale | If you have decided that you going to buy pellet mills, then I am very sure that you must have many questions to ask about the pellet mills. One of... | |

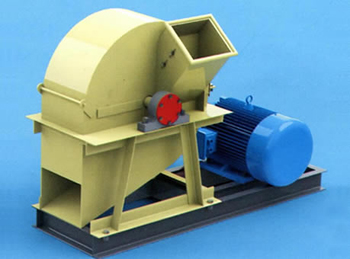

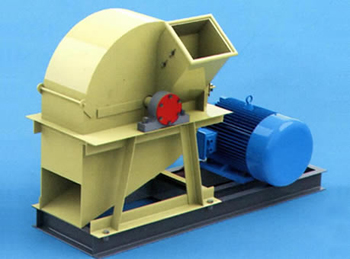

| Reliable Wood Chipper Price/Wood Chipper Supplier | Reliable Wood Chipper Price/Wood Chipper Supplier Introduction Based on wood processing industrial development and special requirements, reliable w... | |

| Wood Chipper Shredder for Sale/Wood Chipper Price | For proper working of biomass briquette press and drying machine in the biomass briquetting machine, size of biomass waste is important. Wood chipp... |

Same products

| HSC Paper Sheeting Machine | Seller: Suzhou Paper Saw King Technology Co.,Ltd | HSC Paper Sheeting Machine Product Description HSC Paper Sheeting Machineincorporates an advanc... | |

| Bottom Feed Slitting Rewinder | Seller: Suzhou Paper Saw King Technology Co.,Ltd | Bottom Feed Slitting Rewinder Product Description The bottom feed slitting rewinderreceives pap... | |

| HX Tape Laminating Slitting Rewinder | Seller: Suzhou Paper Saw King Technology Co.,Ltd | HX Tape Laminating Slitting Rewinder Product Description The HX Tape Laminating Slitting Rewind... | |

| Full Servo Band Saw Paper Slitter | Seller: Suzhou Paper Saw King Technology Co.,Ltd | Full Servo Band Saw Paper Slitter Product Description The Full Servo Band Saw Paper Roll Slitte... | |

| Z1500 Circular Saw Paper Roll Slitter | Seller: Suzhou Paper Saw King Technology Co.,Ltd | Z1500 Circular Saw Paper Roll Slitter Main Characteristics Z1500 Circular Saw Paper Roll Slitte... |