Professional Excellent Biomass Pellet Machine Business Plan

Biomass pellets are widely used in various industries, such as power industry, heating industry and feeding industry, and so on. Besides these wide appliance, they are much comparative than other traditional fuel in cost, energy content and burning result or environment effectiveness. However, the technical process of biomass pellet is much complex, we should know for further developing professional excellent biomass pellet machine business plan.

1. Biomass Material Collection

we should take three main questions into consideration, the first one is factory service radius. The second one is supping form with which farmer provided to factory. The last one taken to been consideration is moisture content of the biomass material, in other words, the degree of material are winded, exposed and dehydrated by wind or sun.

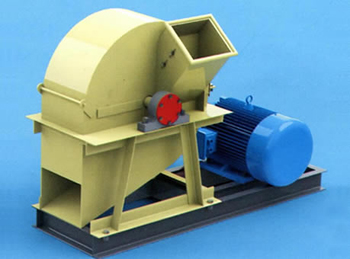

2. Biomass Material Crushing

If they are sawdust or rice husk, it does not need to be crush. But it is essential to be crushed for straw material by crushing machines. The crushing degree is determinate by the pellets size.

3. Biomass Material Drying

The biomass material’s moisture content is required as 8%-20%, if the material is too dry, which can be easy to make the biomass pellet carbonization or fracturing. In the opposite, if it is too wet, which will cause a larger quantity of water vapor.

4. Pre- pelletizing Process

Pre-pelletizing is in order to boost productivity, that is, before pelletizing, the material are pre-pelletized to extract gas, reduce volume and increase density.

5. Heating Process

The purpose of heating process is exist into two roles, in one aspect, which make the ligation soft with the effect of adhesive. In the other aspect, which get the raw material soft to easy for pelletizing. Besides these purpose, which also impact the working efficiency of machine, for the rod forming machine, if the heating temperature is too high, which will result into pellets lower density, and thereby, it will make the pellets easy break.

6. Shaping Process

This process is carried out into sleeve, its inner diameter is much bigger than pellets diameter, so as to biomass pellets eliminate partial stress, with the lowing of temperature, making the pellets shape fixed.

With the assumption that you are facing dilemma of above mentioned description, please refer to, and contact us though leaving message by . And of course, we looking forward establishing mutual relationship with you on the professional excellent biomass pellet machine business plan.

Contact Infomation

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

Send product request

Other supplier products

| Biomass Pellet Plant for Hot Sale/Biomass Pellet Plant Supplier | Biomass Pellet Plant for Hot Sale/Biomass Pellet Plant Supplier Biomass pellet is a kind of clean fuel which is made of various agro-waste and fore... | |

| Reliable Wood Chipper Price/Wood Chipper Supplier | Reliable Wood Chipper Price/Wood Chipper Supplier Introduction Based on wood processing industrial development and special requirements, reliable w... | |

| Small Straw Pellet Mill for Sale/Small Straw Pellet Mill Supplier | Small straw pellet mill for sale/small straw pellet mill supplier is a machine that takes products and compact them into pellets. There are two mai... | |

| Wood Pellet Production Line Price/Wood Pellet Plant Manufacturer | Wood is one of the most popular raw materials for pellets production in the world. We have rich experience in wood pellets processing from the diff... | |

| Hot Selling Superior Small Wood Sawdust Pellet Mill | There are countless hot selling superior small wood sawdust pellet mill suppliers on the internet, some are manufacturers, and some others are trad... |

Same products

| HSC Paper Sheeting Machine | Seller: Suzhou Paper Saw King Technology Co.,Ltd | HSC Paper Sheeting Machine Product Description HSC Paper Sheeting Machineincorporates an advanc... | |

| Bottom Feed Slitting Rewinder | Seller: Suzhou Paper Saw King Technology Co.,Ltd | Bottom Feed Slitting Rewinder Product Description The bottom feed slitting rewinderreceives pap... | |

| HX Tape Laminating Slitting Rewinder | Seller: Suzhou Paper Saw King Technology Co.,Ltd | HX Tape Laminating Slitting Rewinder Product Description The HX Tape Laminating Slitting Rewind... | |

| Full Servo Band Saw Paper Slitter | Seller: Suzhou Paper Saw King Technology Co.,Ltd | Full Servo Band Saw Paper Slitter Product Description The Full Servo Band Saw Paper Roll Slitte... | |

| Z1500 Circular Saw Paper Roll Slitter | Seller: Suzhou Paper Saw King Technology Co.,Ltd | Z1500 Circular Saw Paper Roll Slitter Main Characteristics Z1500 Circular Saw Paper Roll Slitte... |